- 1 Introduction

- 2 Installation

- 2.1 System Requirements

- 2.2 Software Installation

- 2.3 Configuring Python Scripting Support

- 2.4 Configuring the IBM Rational DOORS Integration

- 2.5 Uninstall INCHRON Tool-Suite

- 2.6 Re-install INCHRON Tool-Suite

- 3 Basics

- 4 Projects

- 5 Online Help

- 6 System Modeling

- 6.1 Modules

- 6.2 Module System

- 6.2.1 Concept of Module System

- 6.2.2 Adding and Removing System Elements

- 6.2.3 Drag & Drop and Copy & Paste

- 6.2.4 Project Information

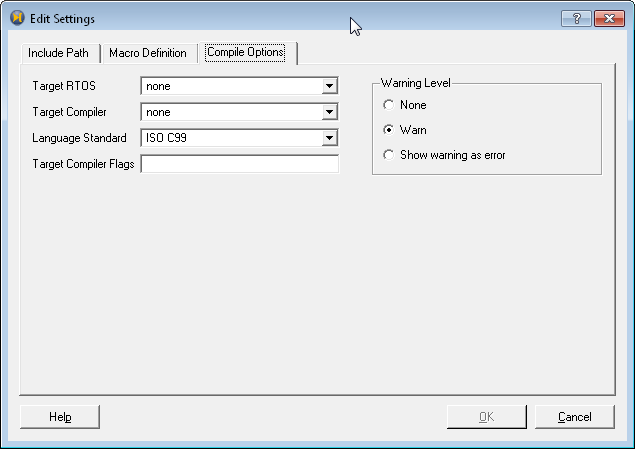

- 6.2.5 Compiler And Preprocessor Options

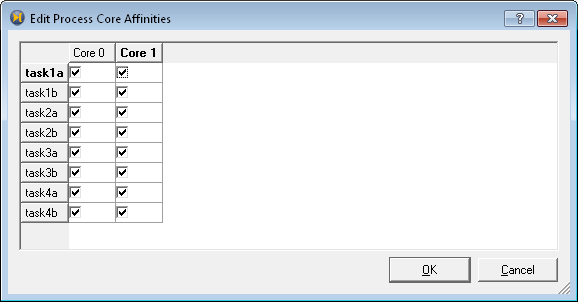

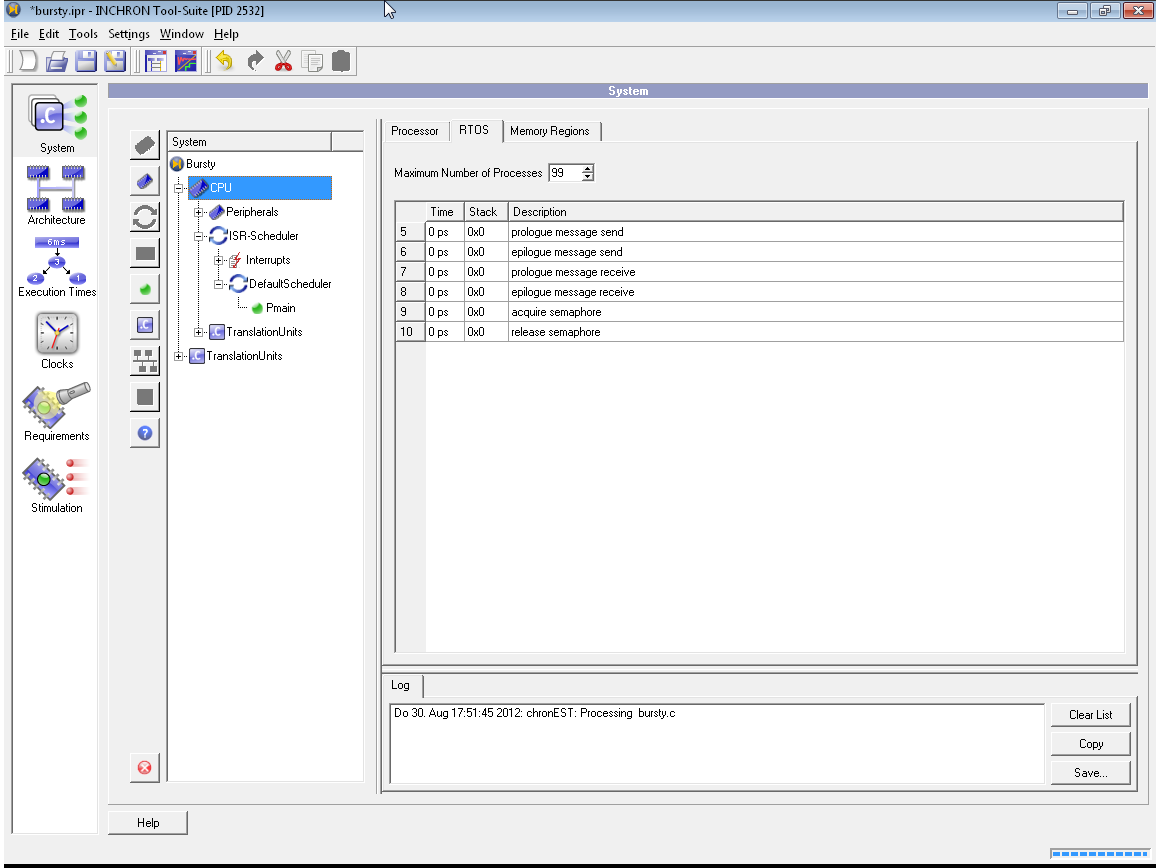

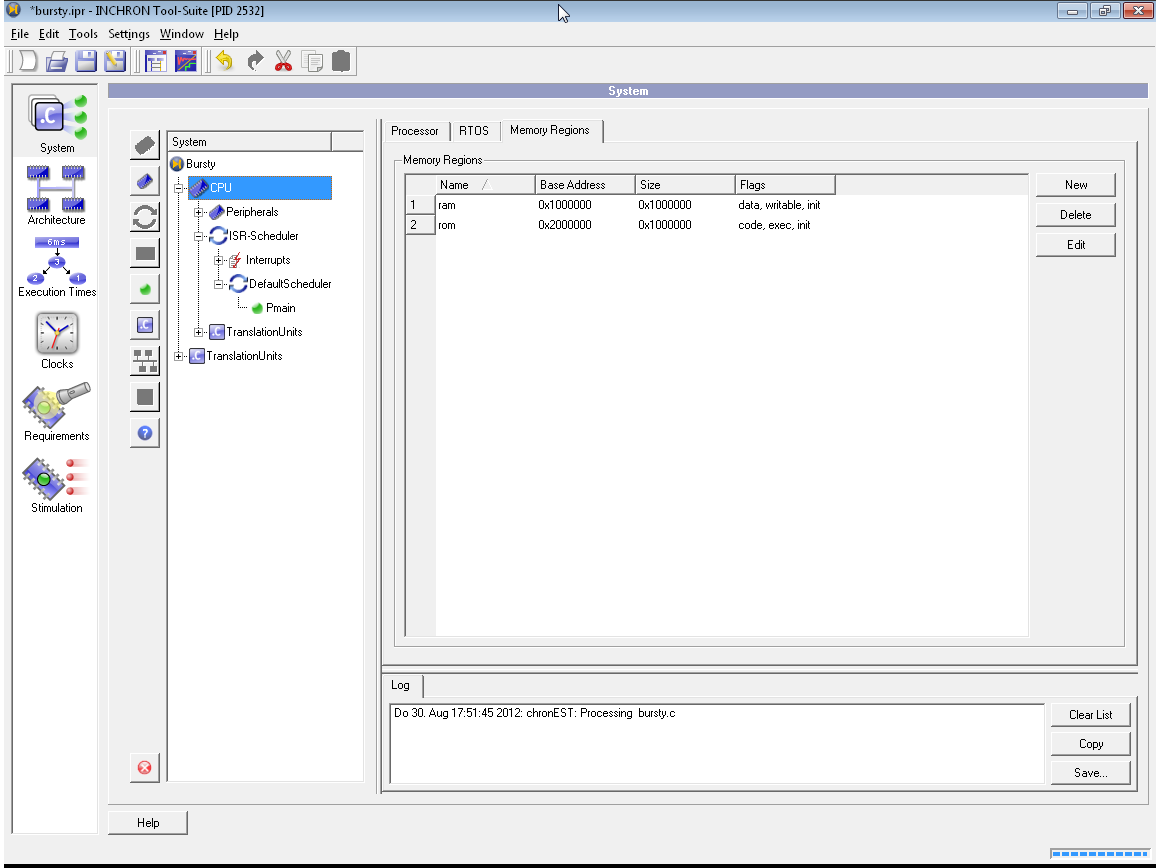

- 6.2.6 Microprocessors

- 6.2.7 Peripheral Components

- 6.2.8 Add Source Files

- 6.2.9 Scheduler

- 6.2.10 Defining Processes

- 6.2.11 Modeling AUTOSAR Runnables

- 6.2.12 Modeling Process Dependencies

- 6.2.13 Event Chains

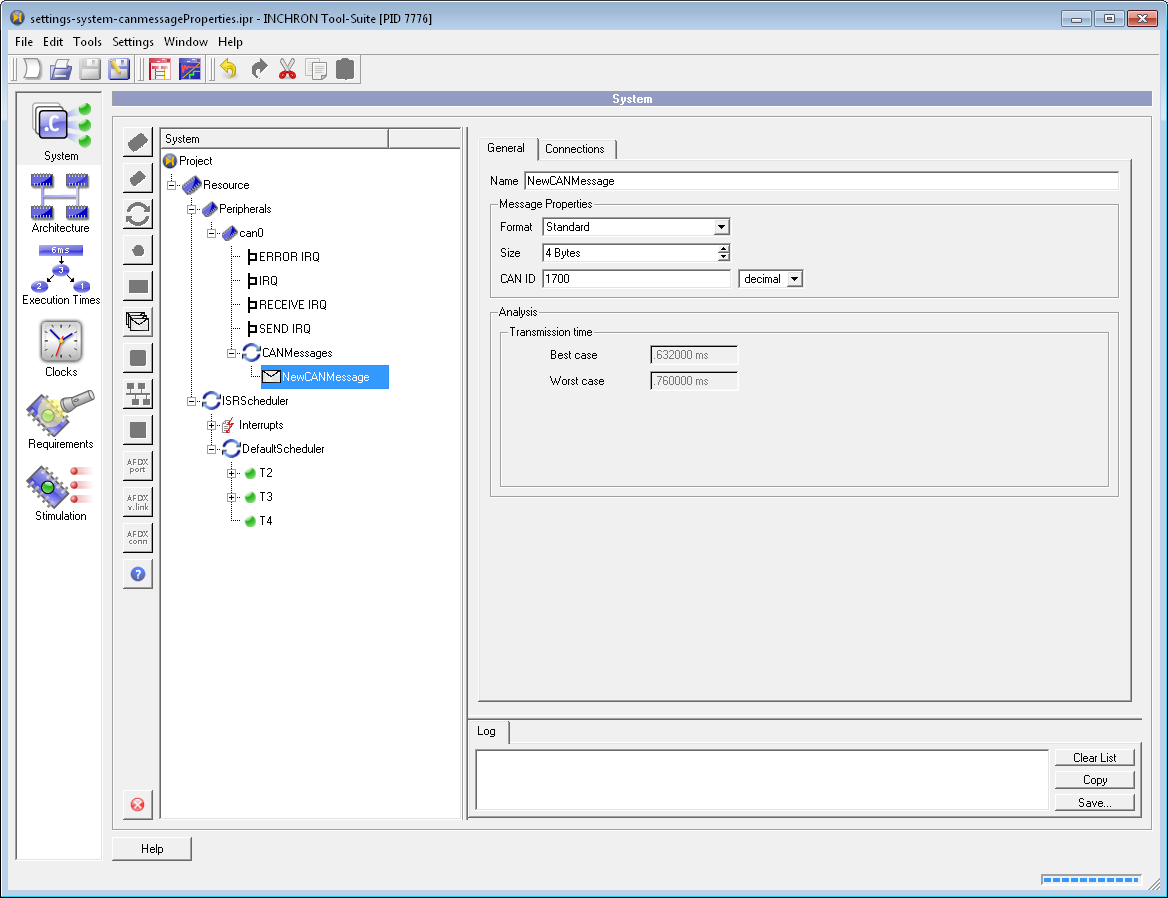

- 6.2.14 Rest Bus Model

- 6.3 Module Architecture

- 6.4 Module Execution Time

- 6.5 Module Clocks

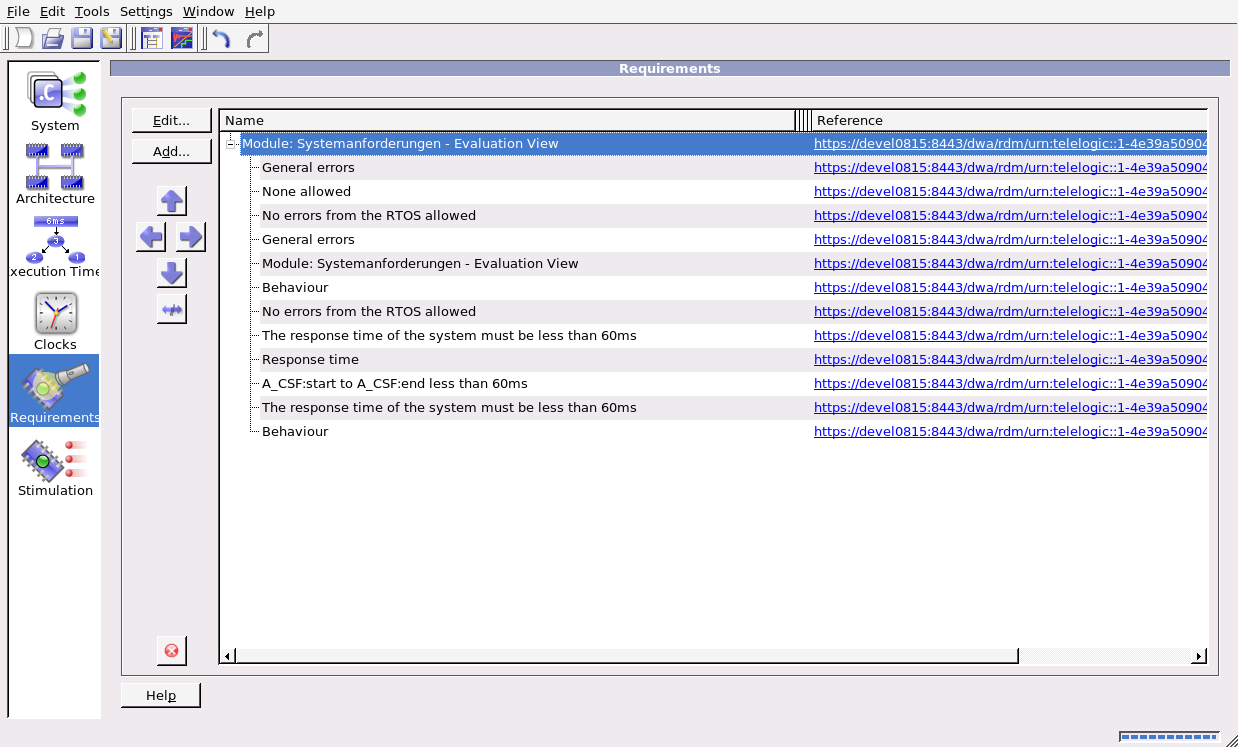

- 6.6 Module Requirements

- 6.6.1 Concept of Module Requirements

- 6.6.2 Requirement Types

- 6.6.3 Process Net Execution Time Requirement

- 6.6.4 Event Net Execution Time Requirement

- 6.6.5 Net Slack Time Requirement

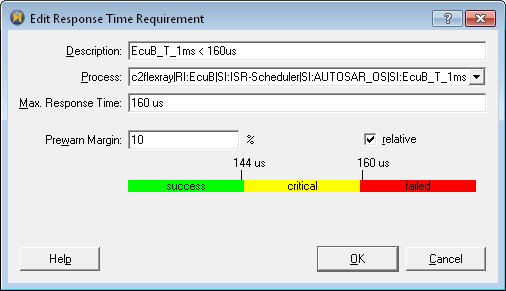

- 6.6.6 Response Time Requirement

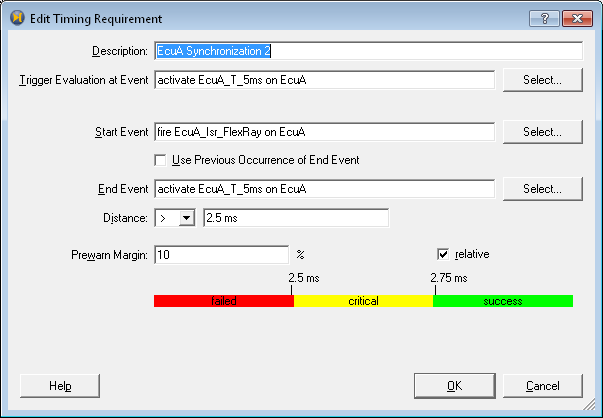

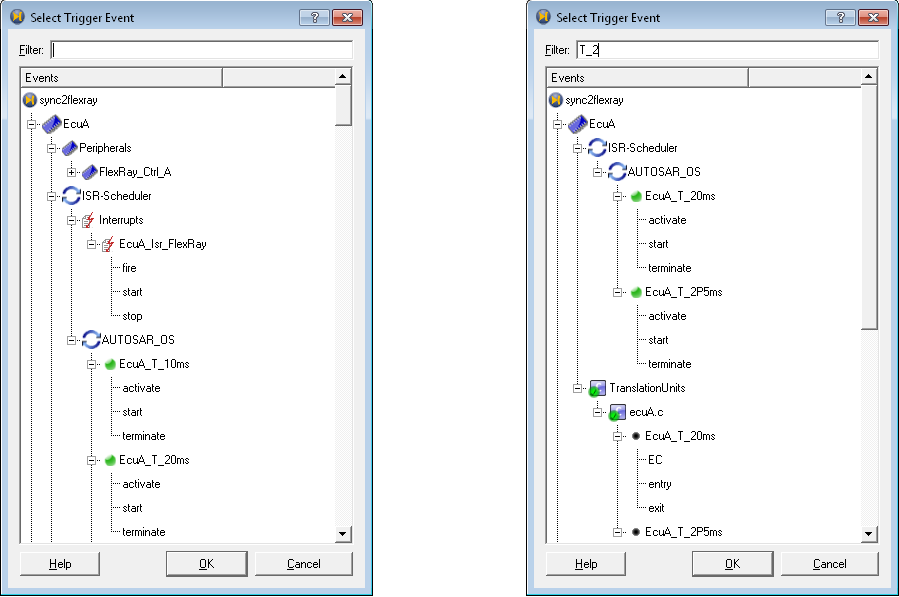

- 6.6.7 Event Timing Requirement

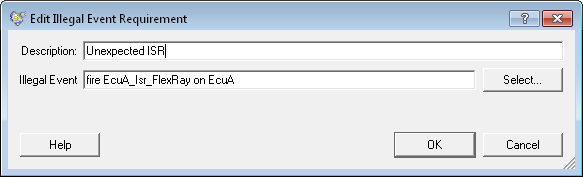

- 6.6.8 Illegal Event Requirement

- 6.6.9 RTOS Failure Requirement

- 6.6.10 Event Periodicity Requirement

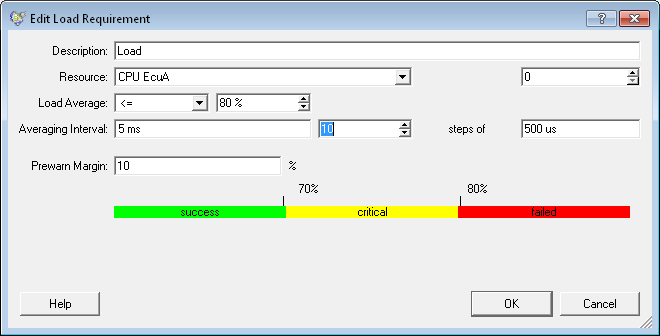

- 6.6.11 Load Requirement

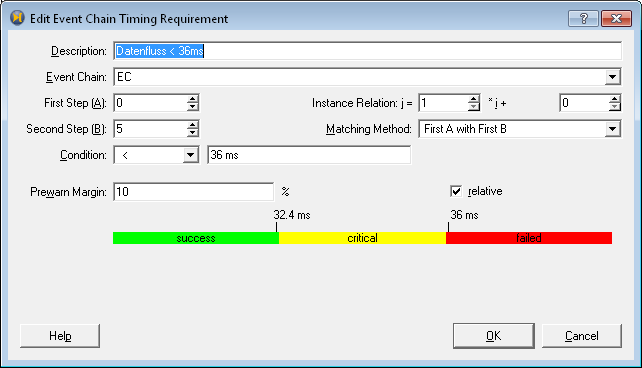

- 6.6.12 Event Chain Timing Requirement

- 6.6.13 Import and Export of Requirements

- 6.7 Module Stimulation

- 6.7.1 Concept of Module Stimulation

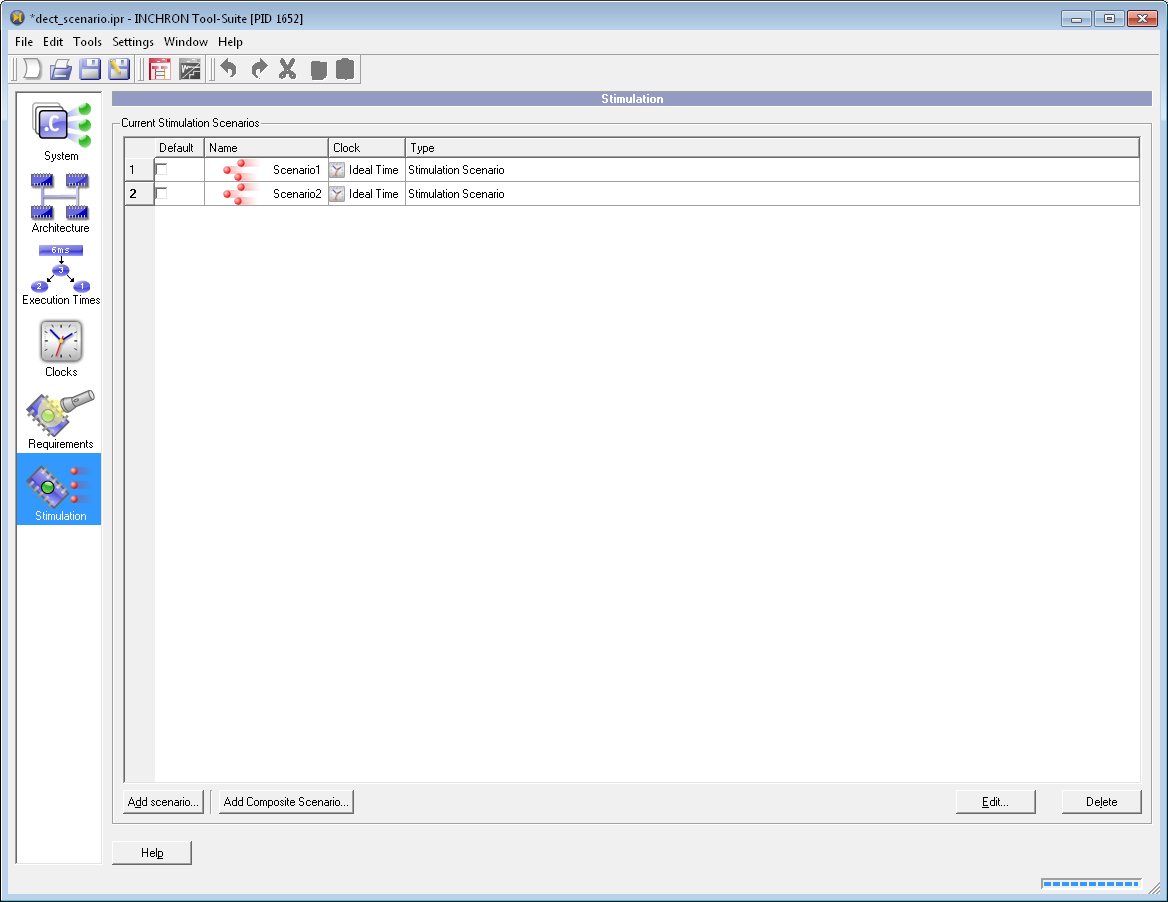

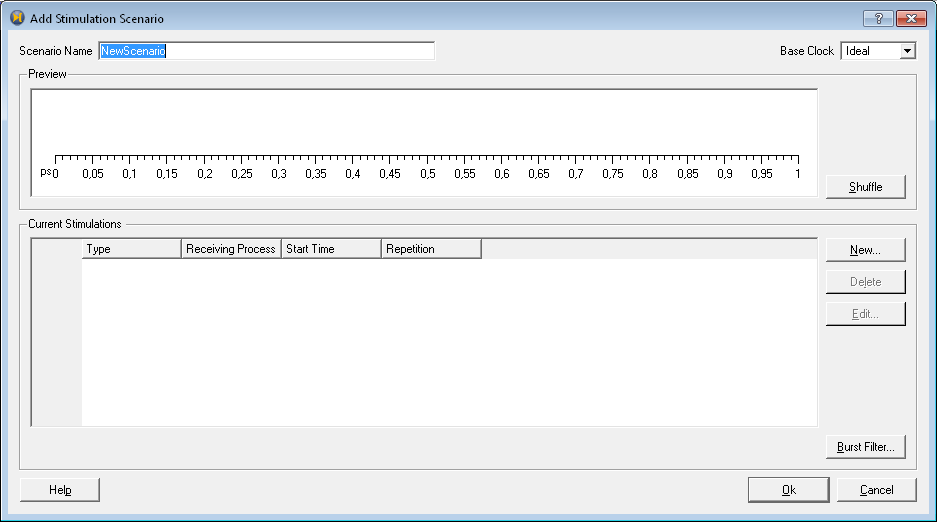

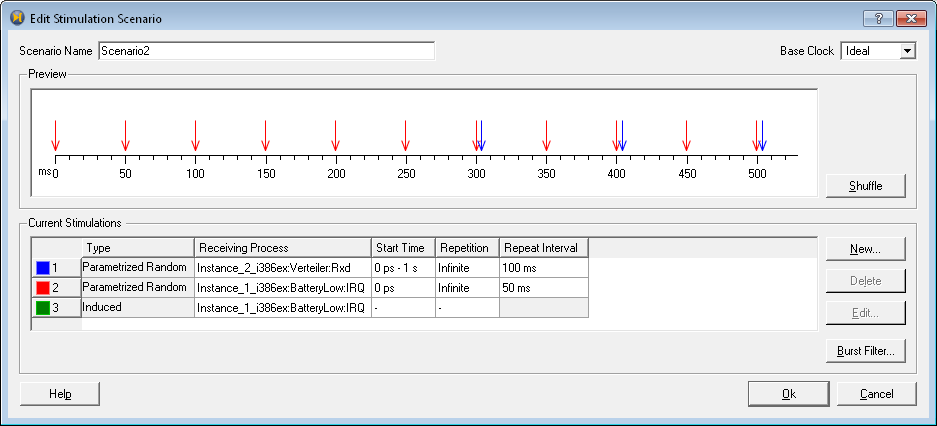

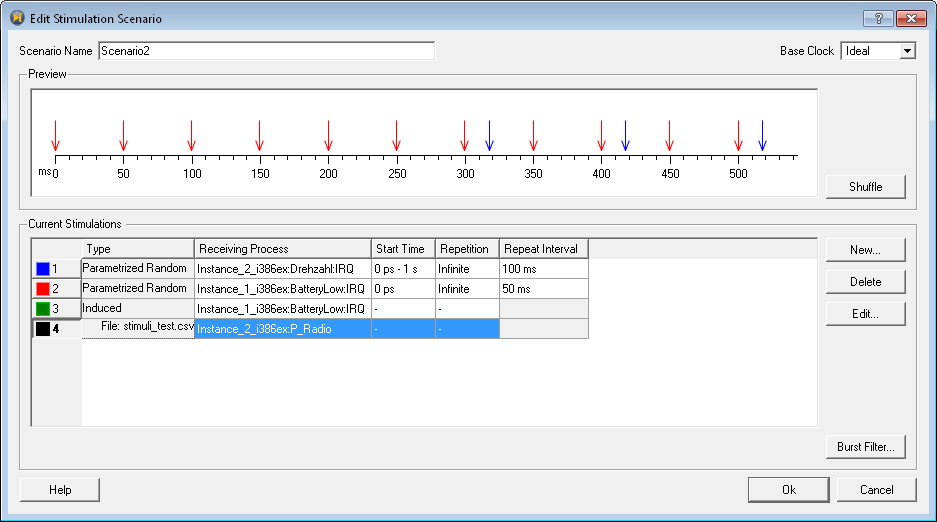

- 6.7.2 Defining a Stimulation Scenario

- 6.7.2.1 Stimulation Scenario Parameters

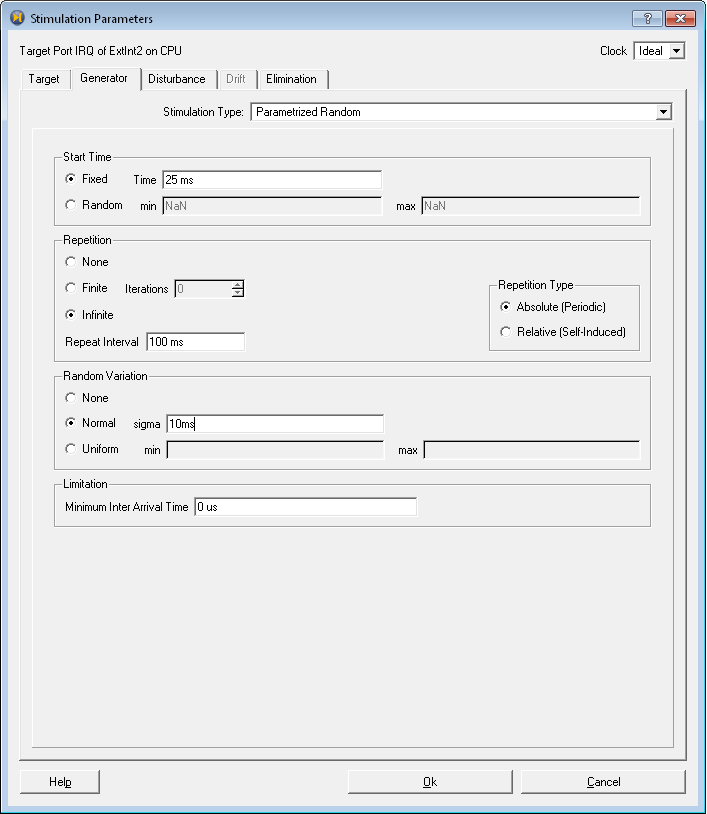

- 6.7.2.2 Stimulation Generators

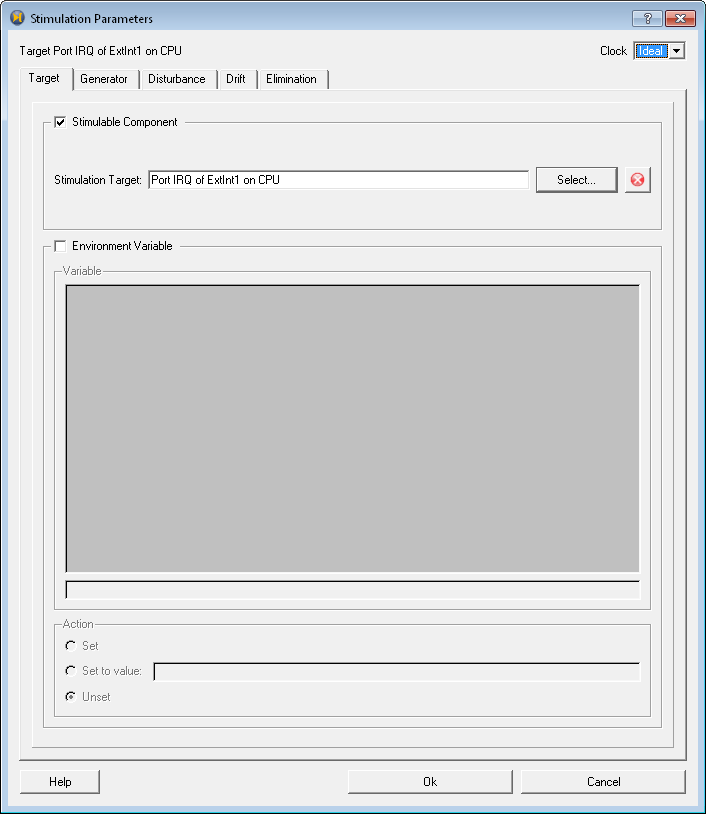

- 6.7.2.3 Selecting the Target

- 6.7.2.4 Configuring the Stimulation Generator

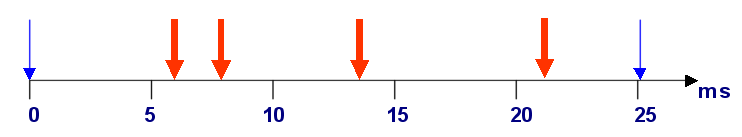

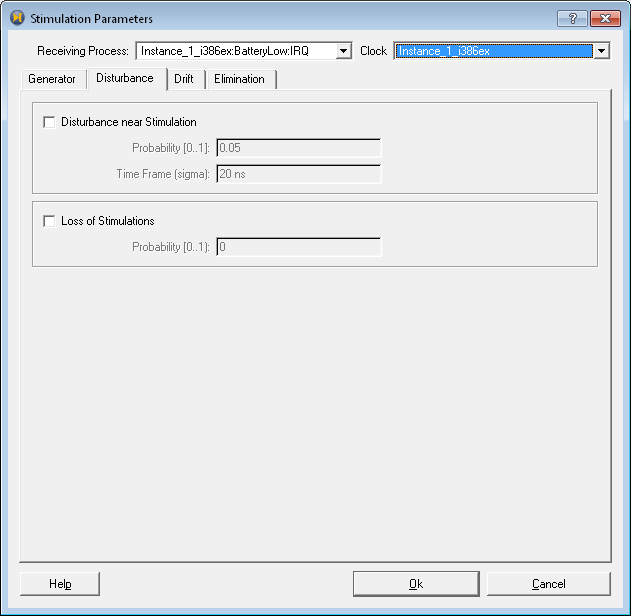

- 6.7.2.5 Stimulation Parameters - Disturbance

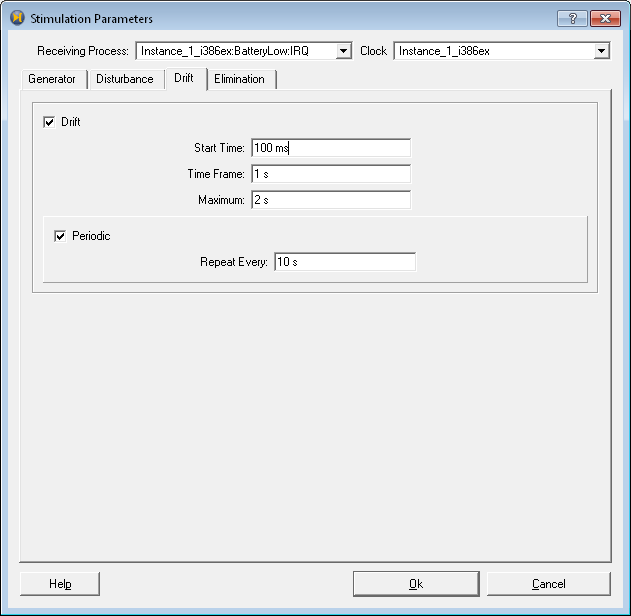

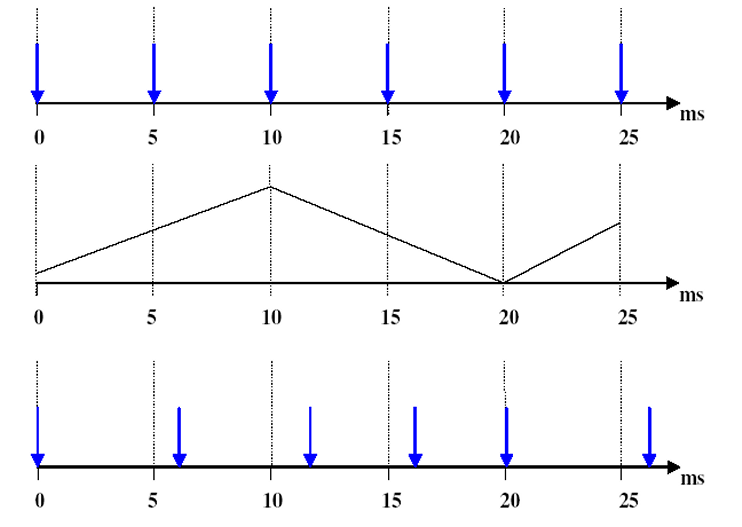

- 6.7.2.6 Stimulation Parameters - Drift

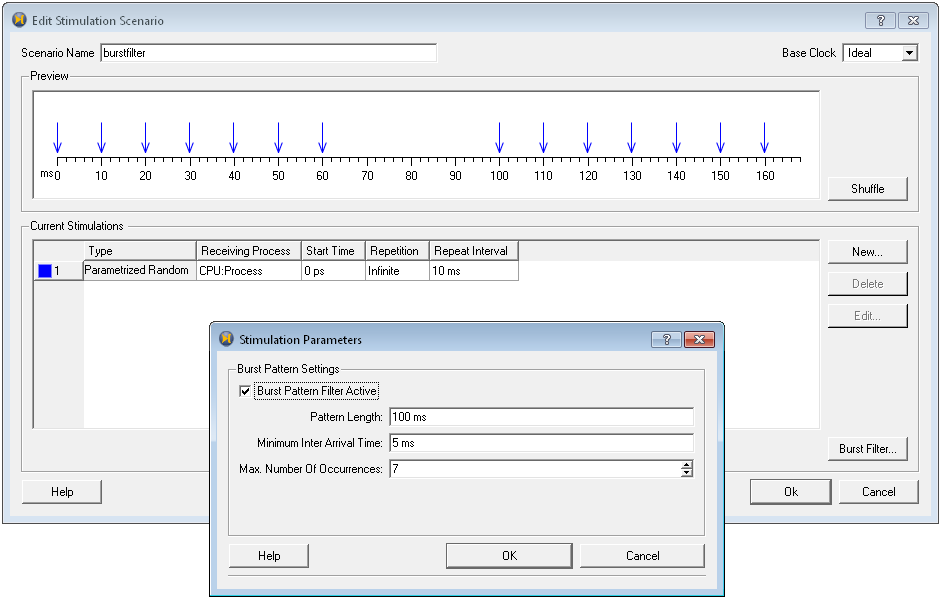

- 6.7.2.7 Limiting Stimulations with a Burst Filter

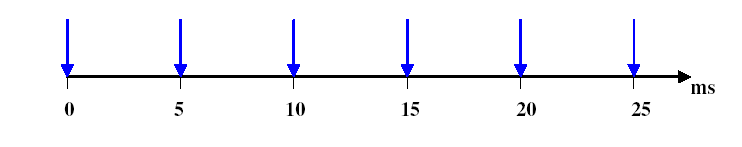

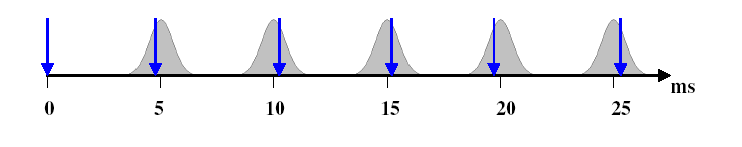

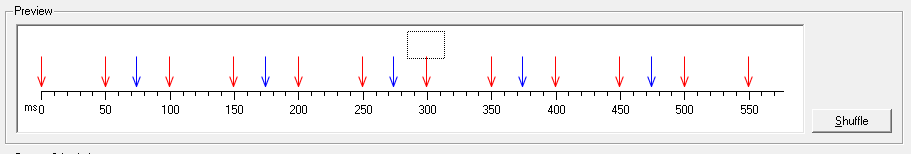

- 6.7.2.8 Stimulation Preview

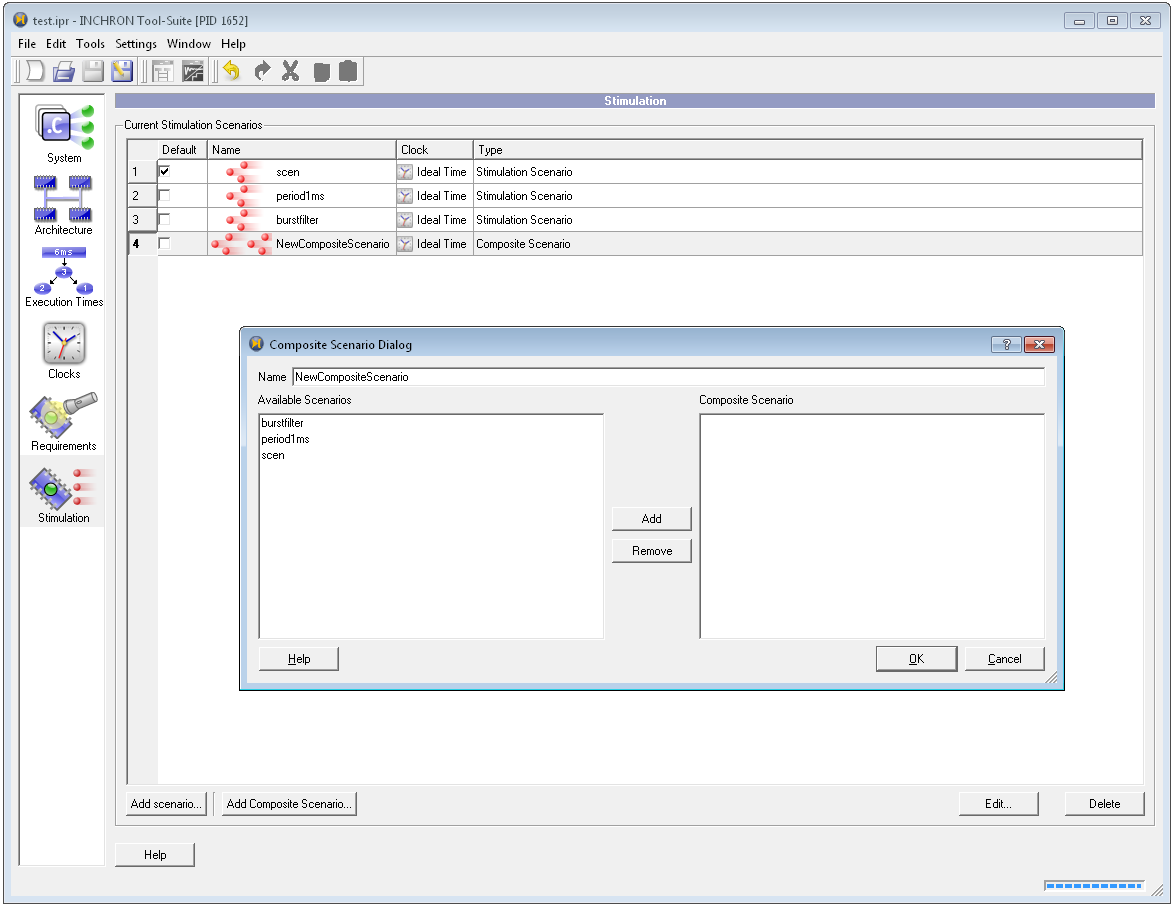

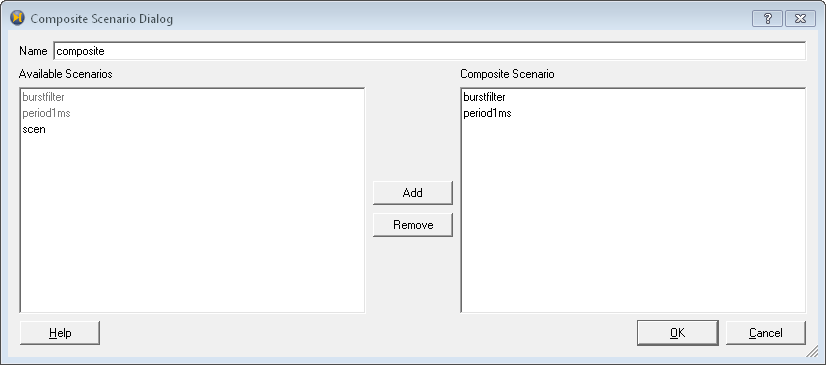

- 6.7.3 Composite Scenario

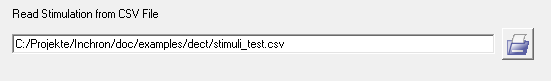

- 6.7.4 Import and Export of Scenarios

- 7 Simulation

- 7.1 The Simulation Concept

- 7.2 Running a Simulation

- 7.3 Automatic Breakpoints

- 7.4 Environment Variables

- 7.5 Stimulation

- 7.6 Real-Time Requirements

- 7.7 Visualization

- 7.7.1 Time Range Filter

- 7.7.2 View Profiles

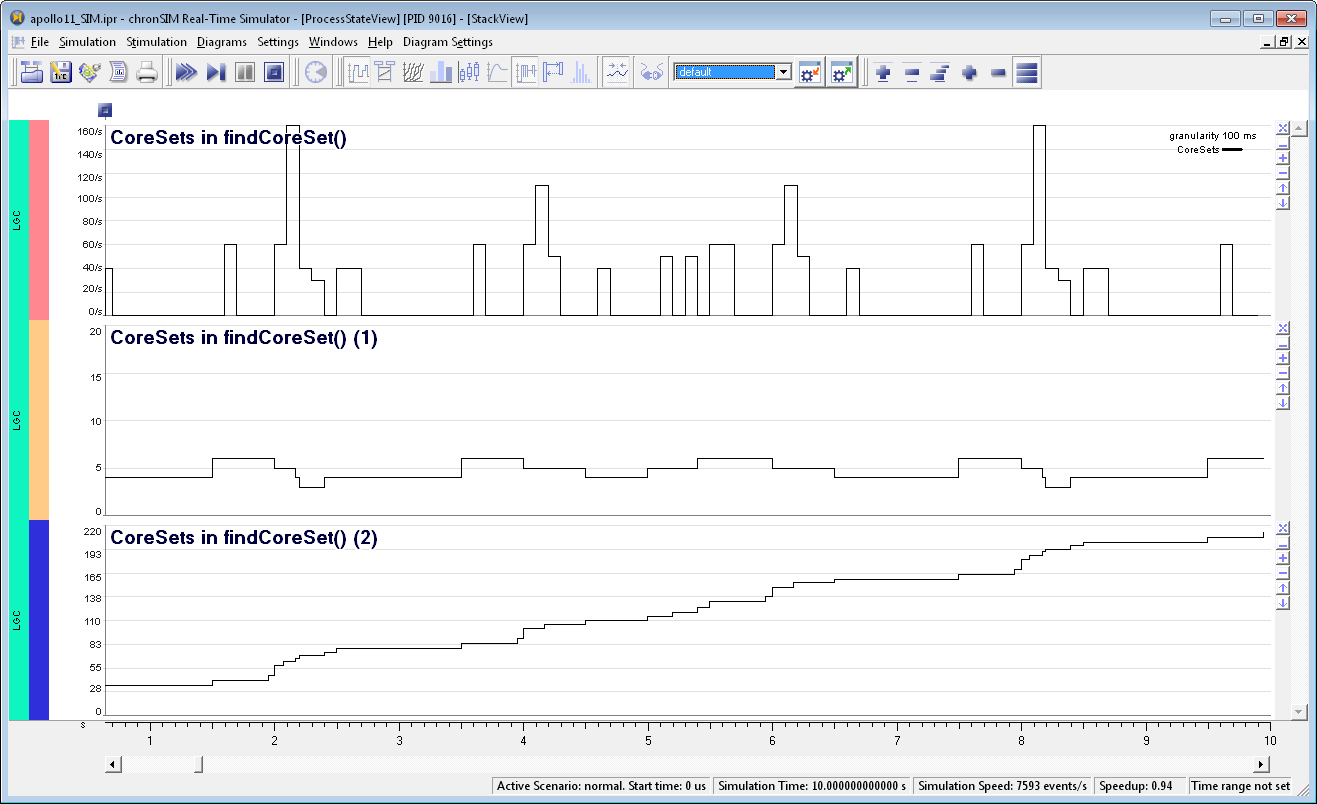

- 7.7.3 Statistics View

- 7.7.4 Diagram Types

- 7.7.5 x/t Diagrams

- 7.7.6 Diagram Usage

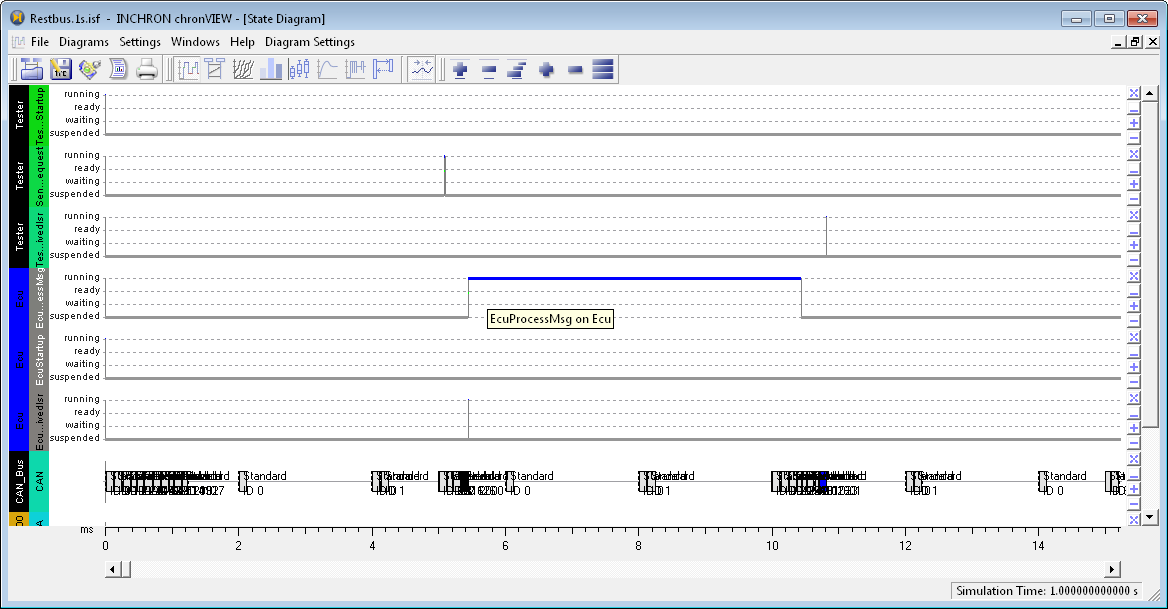

- 7.7.7 State Diagram

- 7.7.8 Gantt Diagram

- 7.7.9 Sequence Diagram

- 7.7.10 Event Chain Diagram

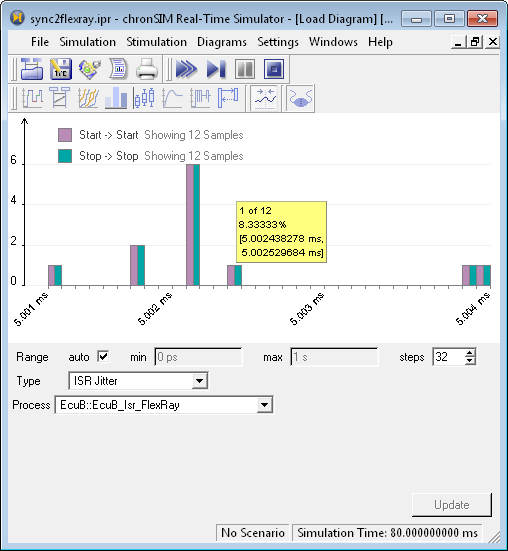

- 7.7.11 Histogram

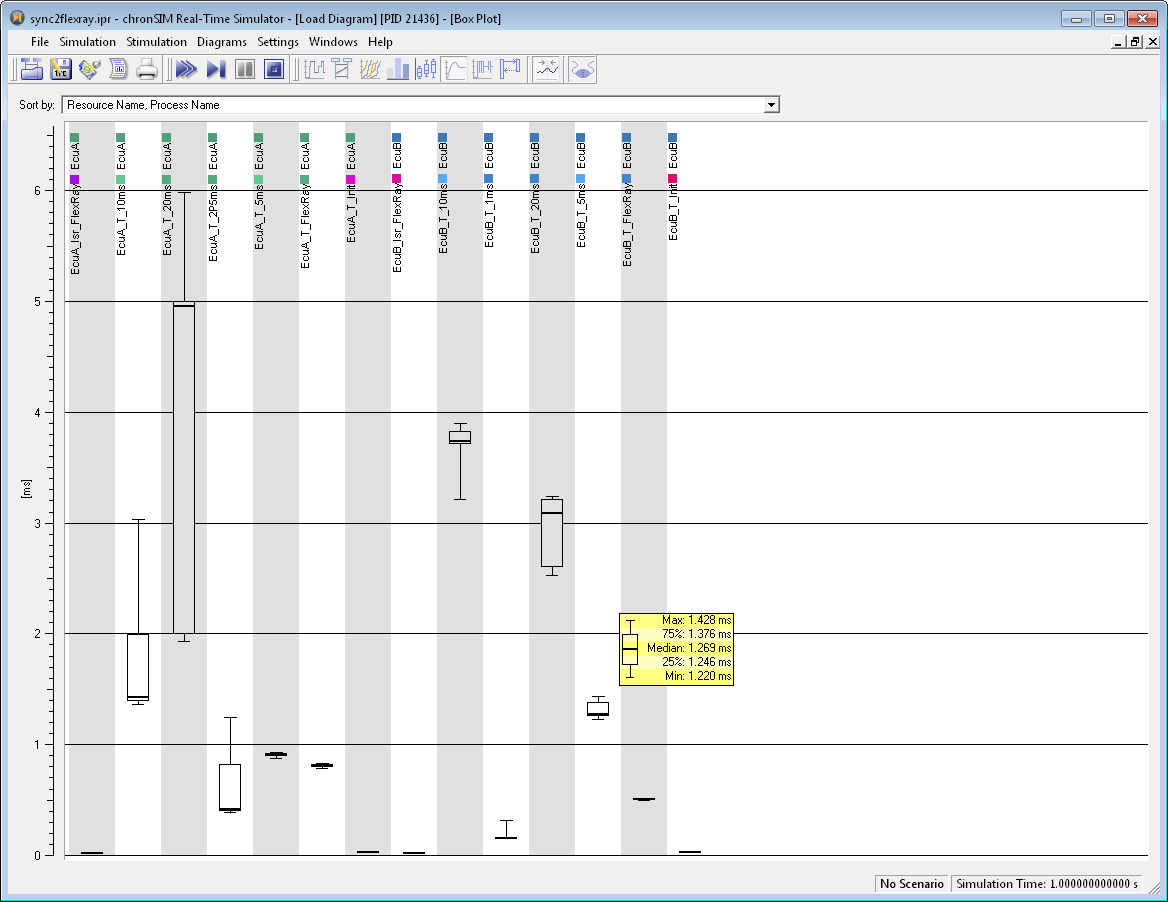

- 7.7.12 Box Plot Diagram

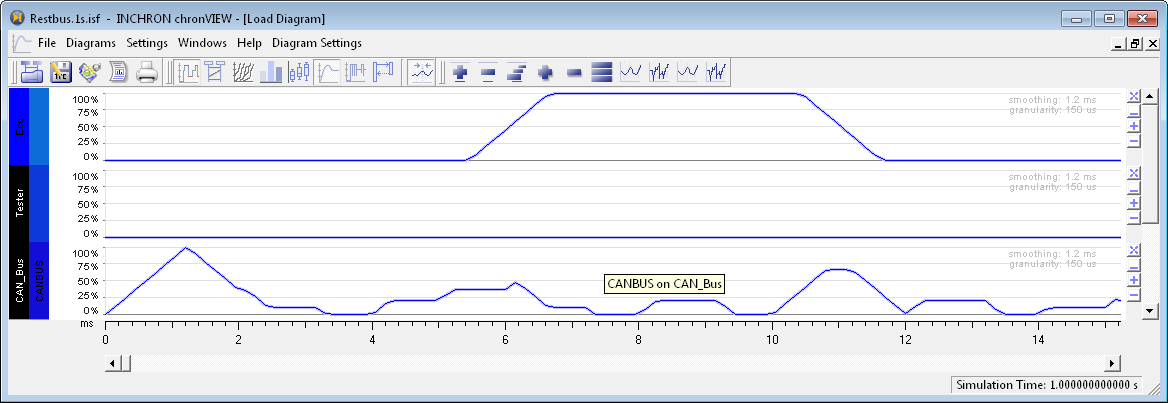

- 7.7.13 Load Diagram

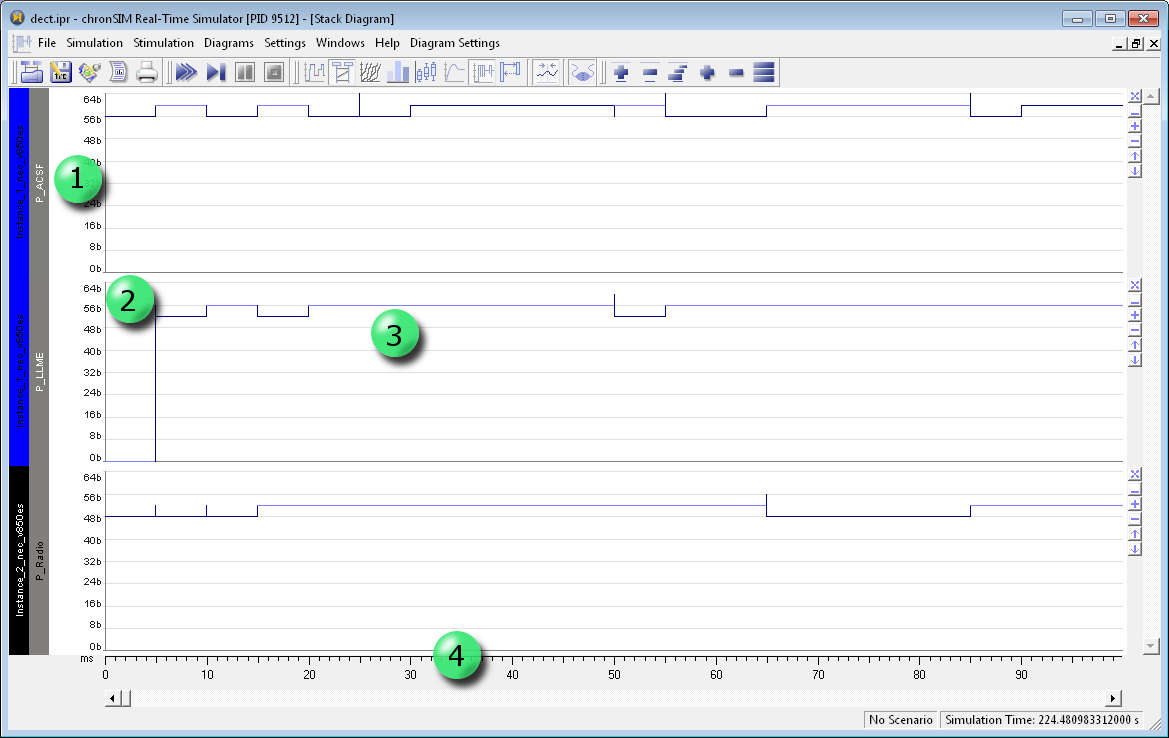

- 7.7.14 Stack Diagram

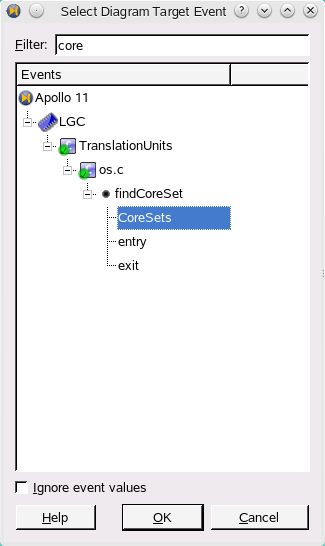

- 7.7.15 Event Diagrams

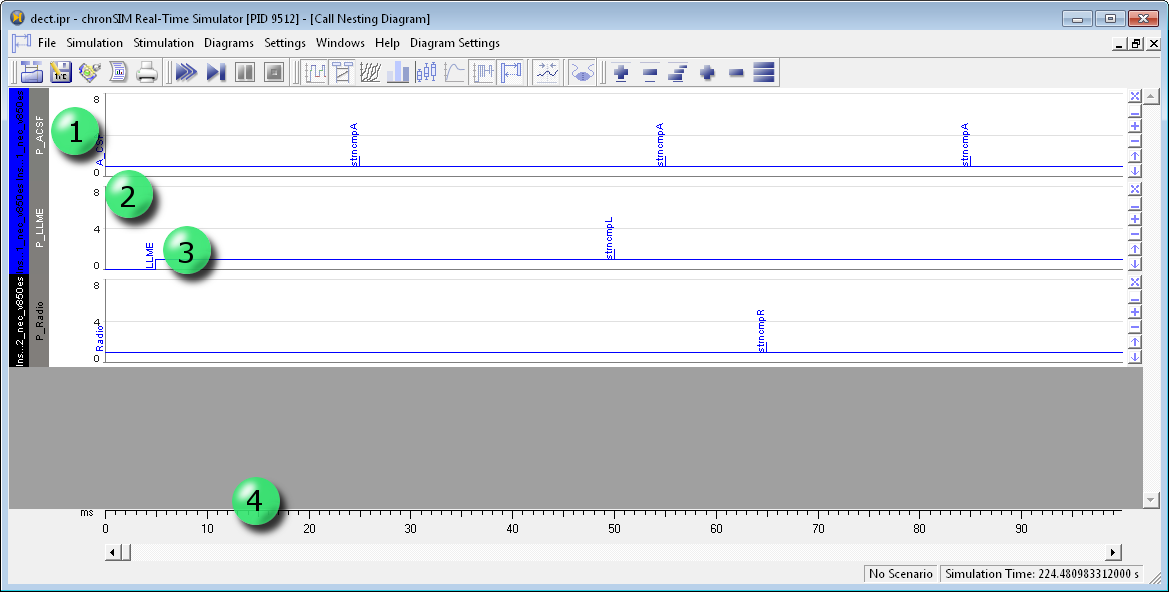

- 7.7.16 Nesting Diagram

- 7.7.17 Console View

- 7.8 Saving and Loading Trace Files

- 7.9 Export of Stimulation Scenarios

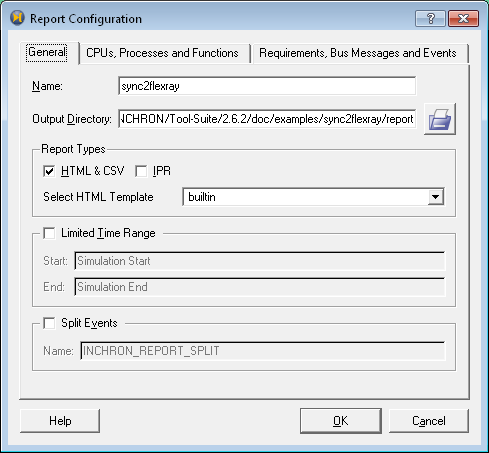

- 7.10 Reporting

- 8 Validation

- 9 Optimization

- 10 Interactive Design of Dynamic Architectures

- 11 Integration with IBM Rational Software

- 12 Subversion Integration

- A Technical Data

- A.1 Target Systems

- A.2 Load Calculation

- A.3 INCHRON Tool-Suite File Formats

- A.3.1 File Format of INCHRON Projects

- A.3.2 File Format of INCHRON Target Models

- A.3.3 File Format of Stimulation Scenarios

- A.3.4 File Format of Requirements

- A.3.5 File Format of View Profiles

- A.3.6 File Formats for Stimulation Data

- A.3.7 File Formats for Simulation Traces

- A.3.8 File Format for Reports

- A.3.9 File formats for Data Exchange

- A.4 Third Party Software

- A.5 Compiler

- B INCHRON Tool-Suite Command Line Tools

- C Peripheral Components

- Index

INCHRON Tool-Suite Software Version 2.9

User Manual #

Copyright © 2006, 2007, 2008, 2009, 2010, 2011, 2012, 2013, 2014, 2015, 2016, 2017, 2018 INCHRON GmbH, Potsdam

- 1 Introduction

- 2 Installation

- 3 Basics

- 4 Projects

- 5 Online Help

- 6 System Modeling

- 7 Simulation

- 8 Validation

- 9 Optimization

- 10 Interactive Design of Dynamic Architectures

- 11 Integration with IBM Rational Software

- 12 Subversion Integration

- A Technical Data

- B INCHRON Tool-Suite Command Line Tools

- C Peripheral Components

- Index

- 2.1 The INCHRON Tool-Suite Setup is Being Loaded

- 2.2 INCHRON Tool-Suite Installation Question

- 2.3 INCHRON Tool-Suite Setup Welcome Page

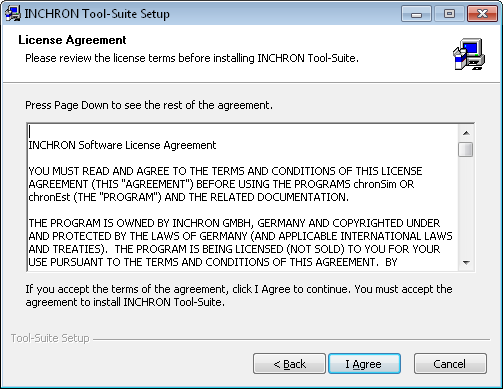

- 2.4 INCHRON Tool-Suite Software License Agreement

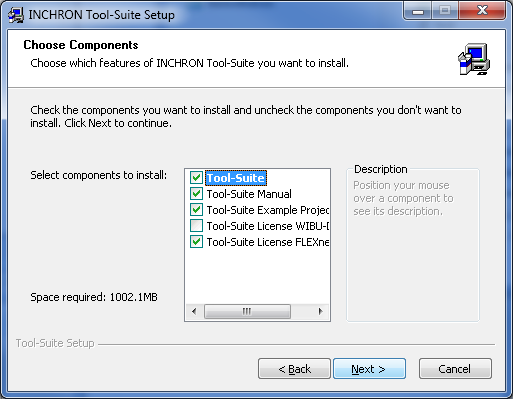

- 2.5 Selection of Software Modules for Installation

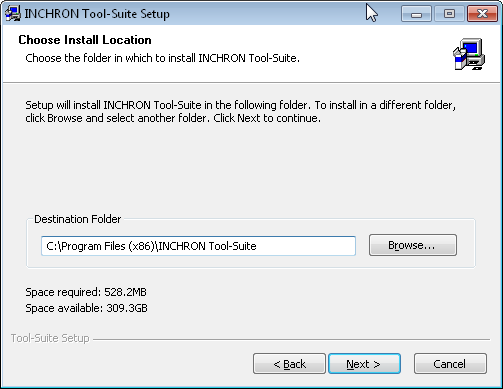

- 2.6 INCHRON Tool-Suite Installation Path

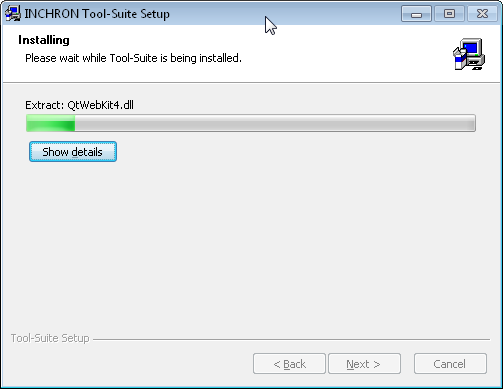

- 2.7 Installation Progress

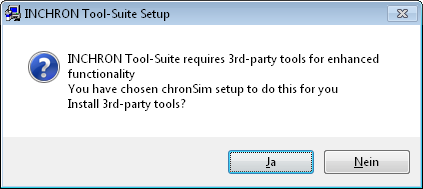

- 2.8 Installation of 3rd Party Tools

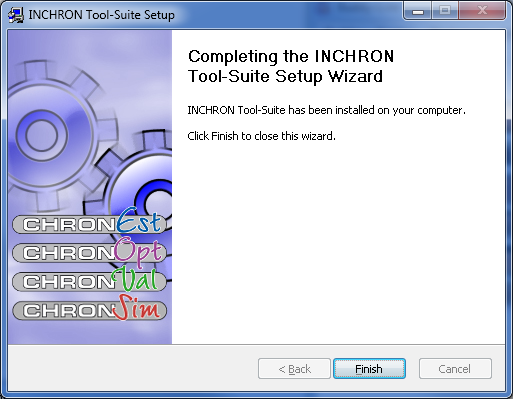

- 2.9 The Installation is Complete

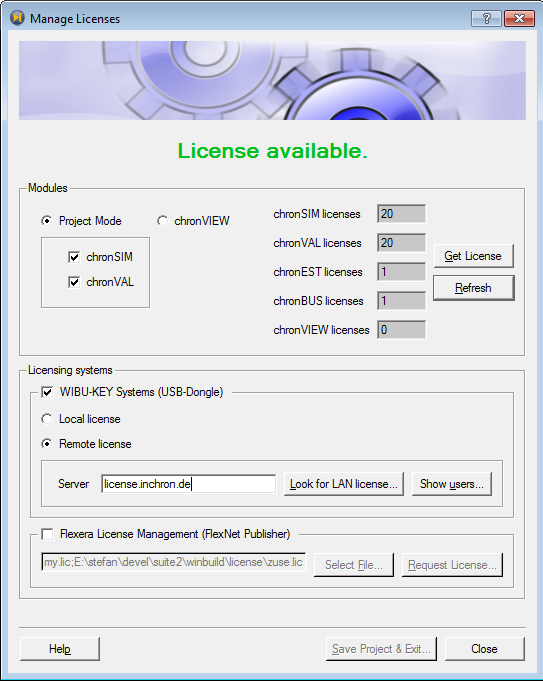

- 2.10 Manage Licenses Dialog

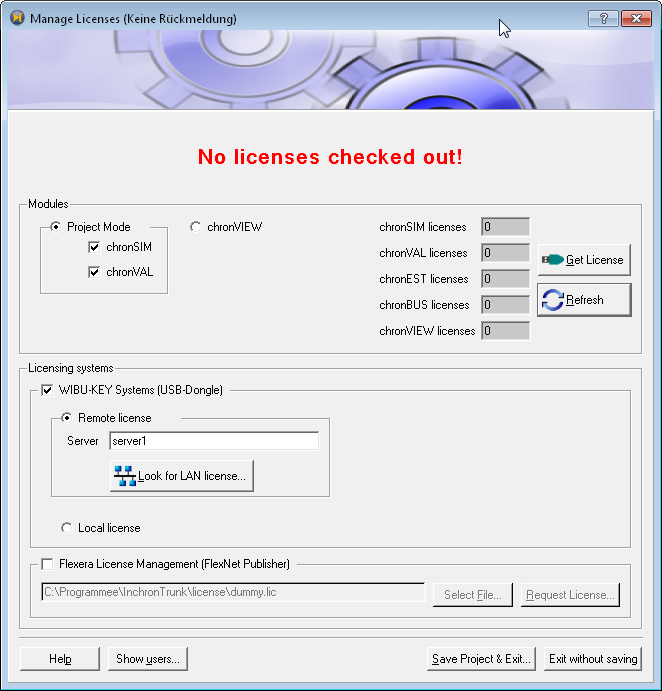

- 2.11 Manage Licenses Dialog

- 2.12 Valid WIBU-KEY License

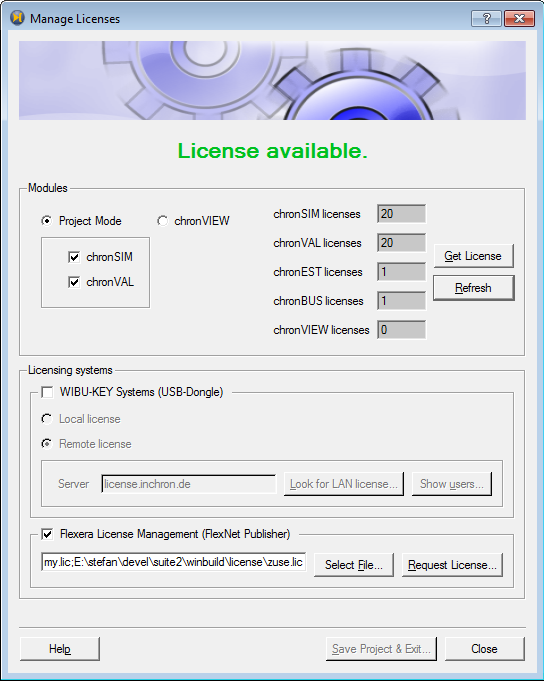

- 2.13 Manage Licenses Dialog with Activated FLEXlm License

- 2.14 Request License Dialog

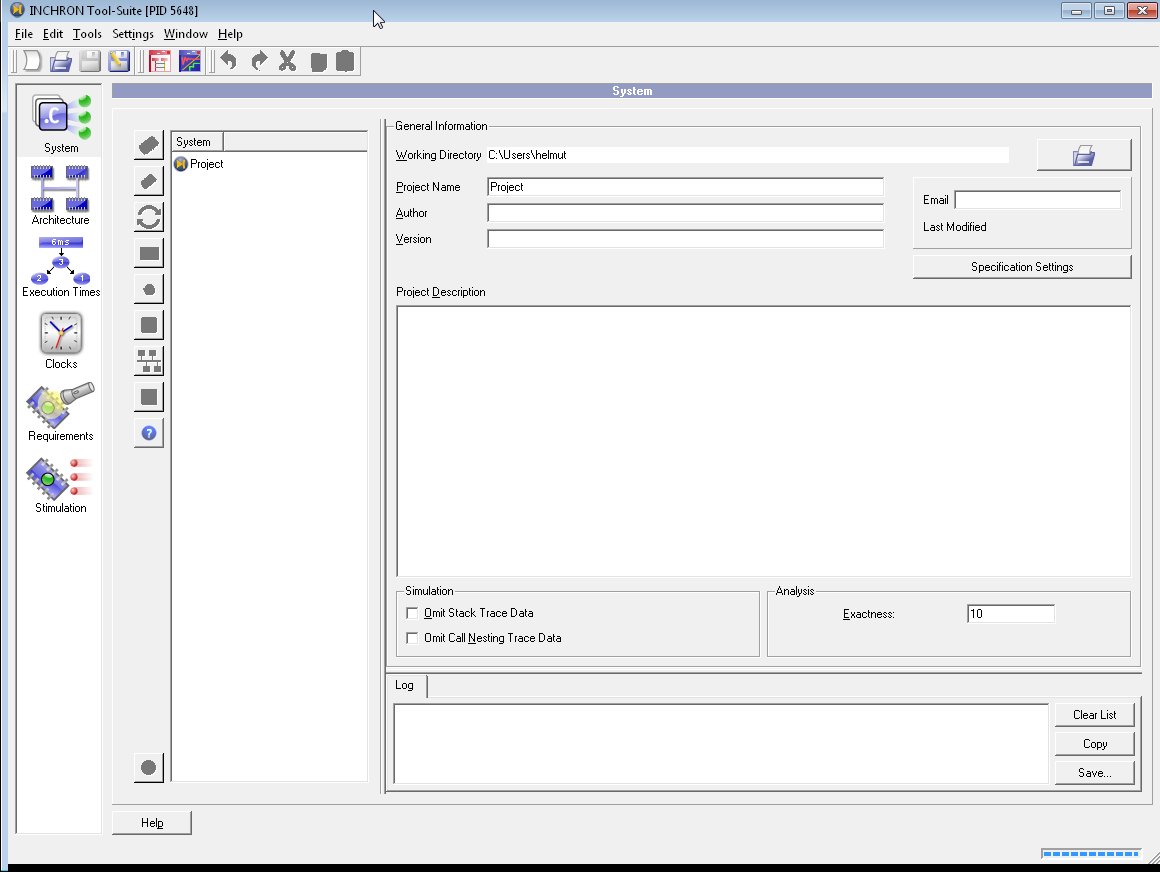

- 2.15 INCHRON Tool-Suite Project Window

- 2.16 INCHRON Tool-Suite Project Window with Example Project

- 2.17 Progress Dialog During Simulation Preparation

- 2.18 INCHRON Tool-Suite Real-Time Simulator Window

- 2.19 Simulation generation failed

- 2.20 State Diagram Window During Simulation

- 2.21 Install wizard for the INCHRON Tool-Suite Python Addon

- 2.22 The Initial Configuration Page

- 2.23 The top section of the Configuration Page

- 2.24 The General section of the Configuration Page

- 2.25 The DOORS Web Access section of the Configuration Page

- 2.26 The bottom section of the Configuration Page

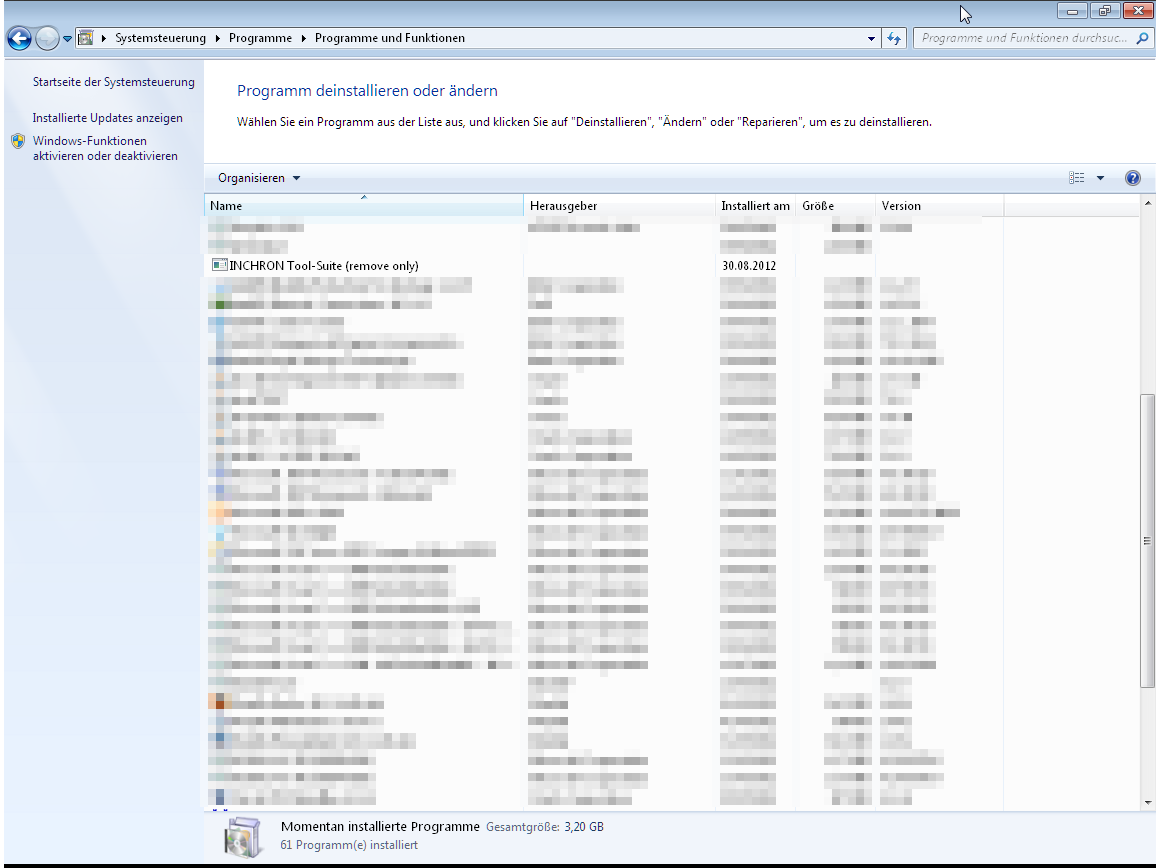

- 2.27 Windows Deinstallation Window

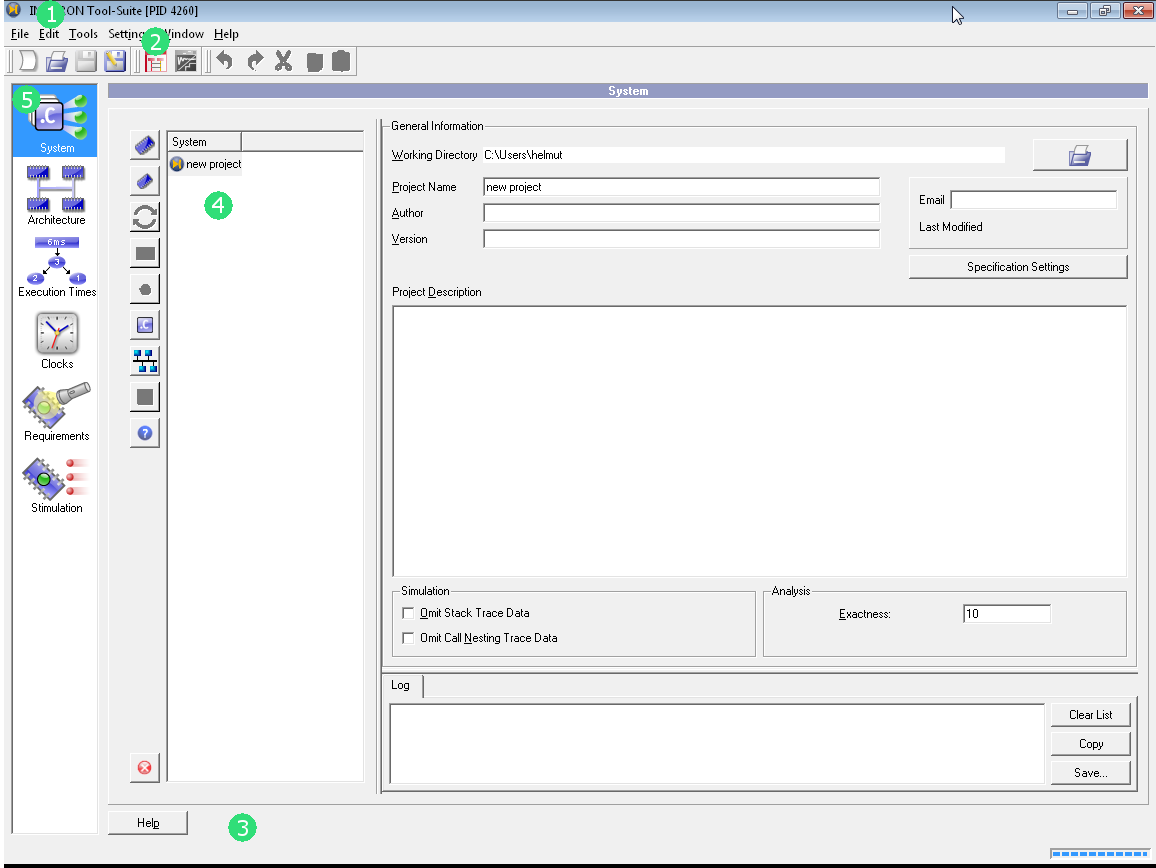

- 3.1 The INCHRON Tool-Suite project mode window

- 3.2 chronSIM Real-Time Simulator window

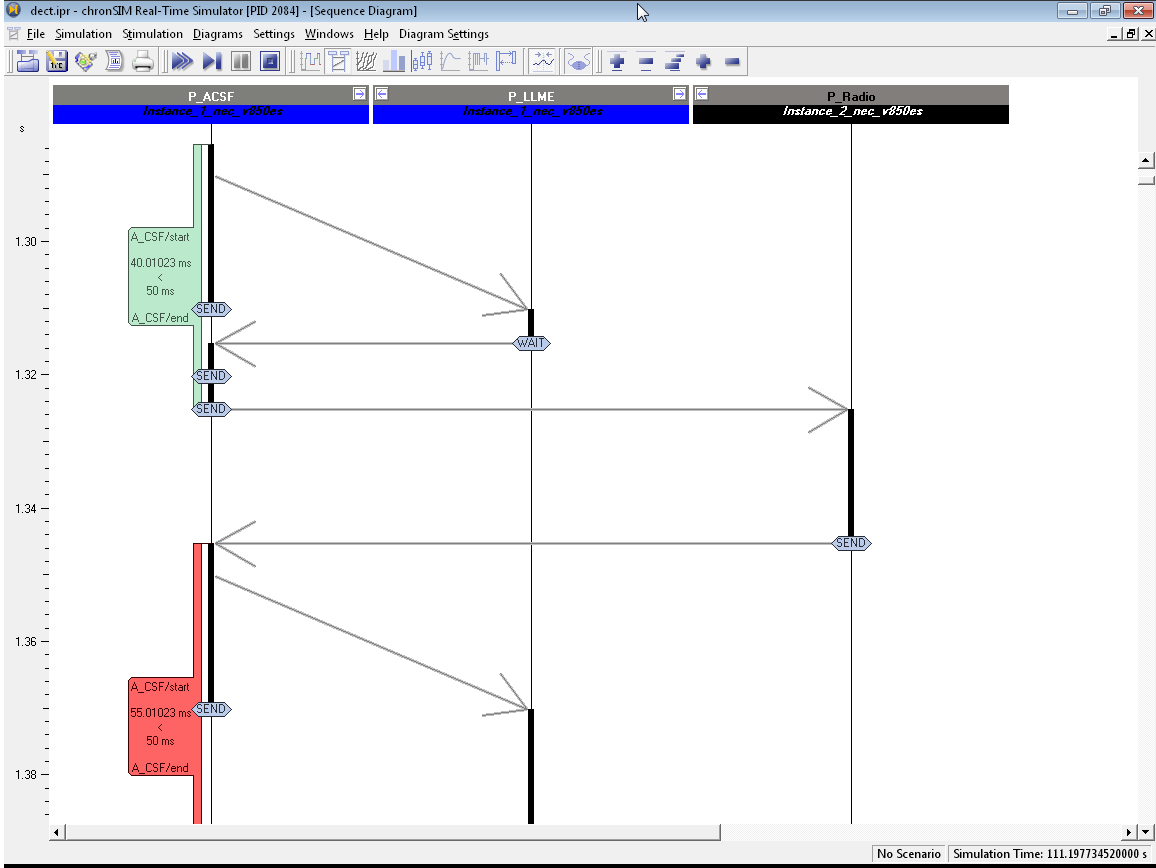

- 3.3 Sequence Diagram With Three Processes

- 3.4 State Diagram With Three Processes

- 3.5 Simulation Control Window

- 3.6 The chronVAL Validation windows

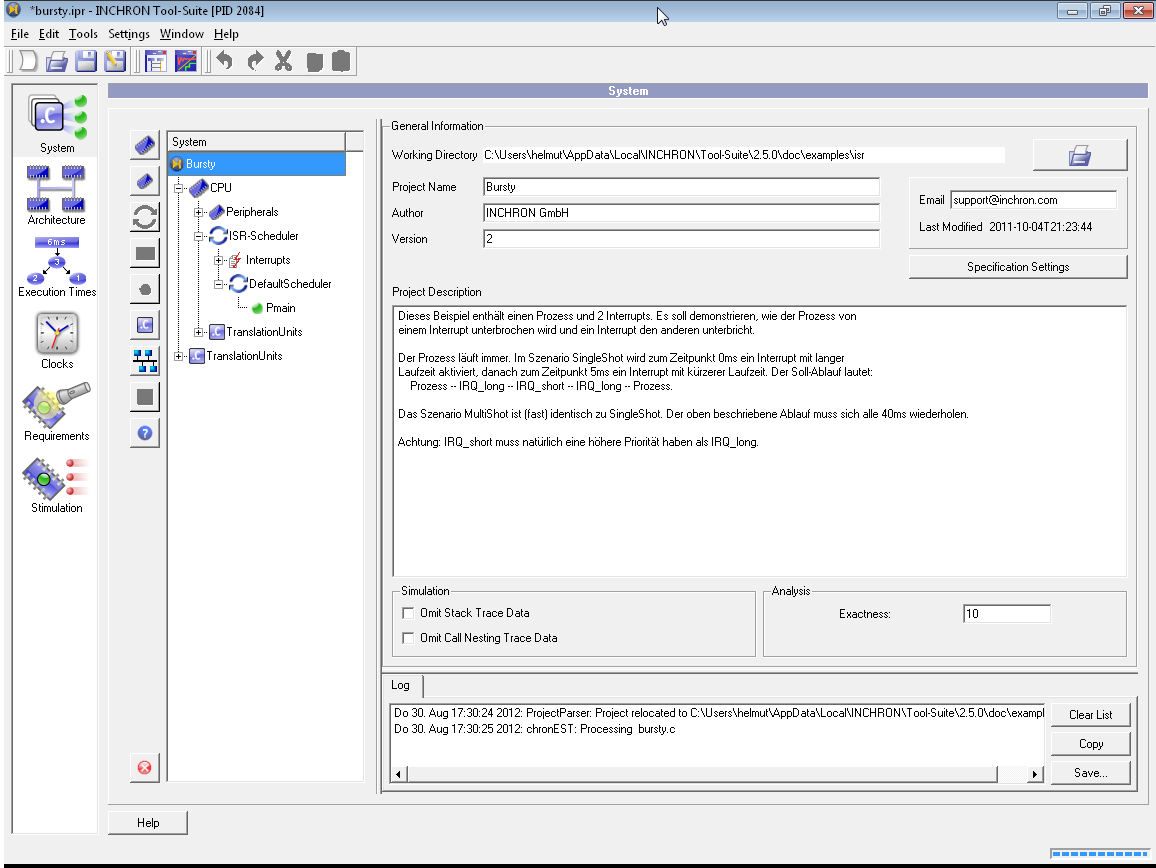

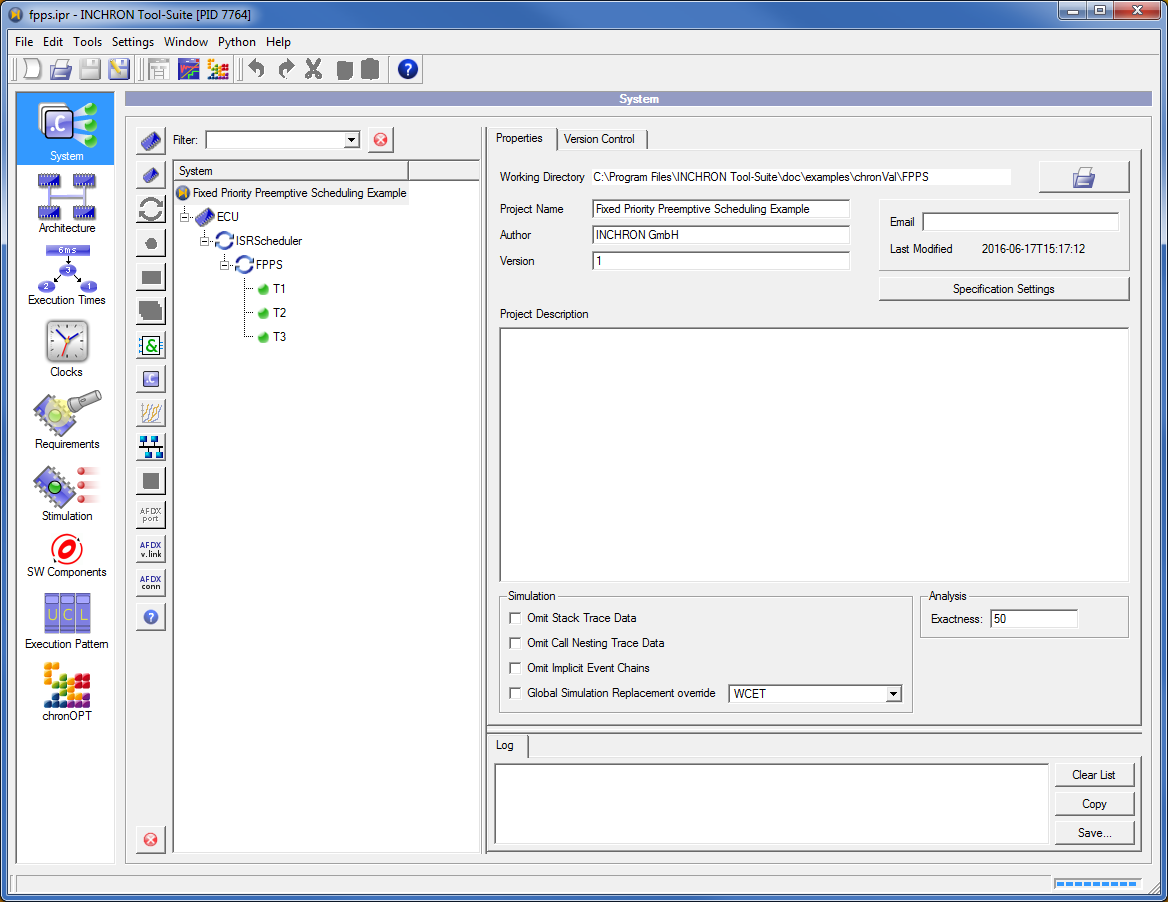

- 4.1 Example of Project General Settings

- 4.2 General Settings Dialog

- 4.3 Tool-Suite Update Settings

- 4.4 Tool-Suite Update Status

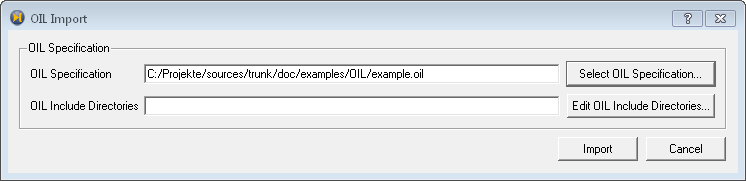

- 4.5 OIL Import dialog

- 4.6 OIL File Selection Dialog.

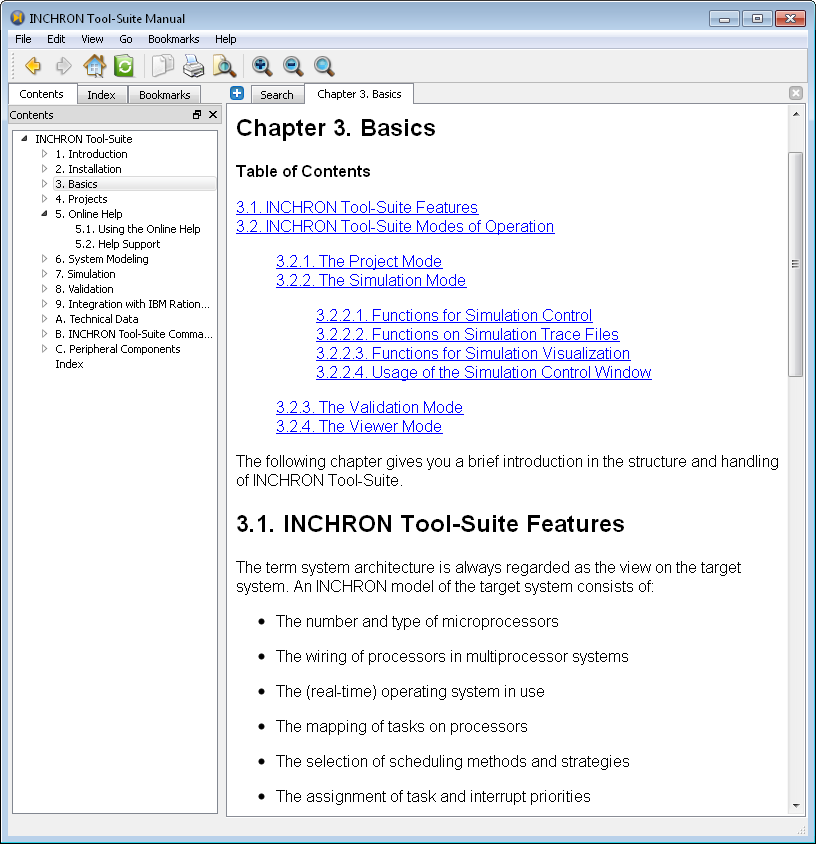

- 5.1 INCHRON Tool-Suite Help Window

- 6.1 Areas of the Project Window

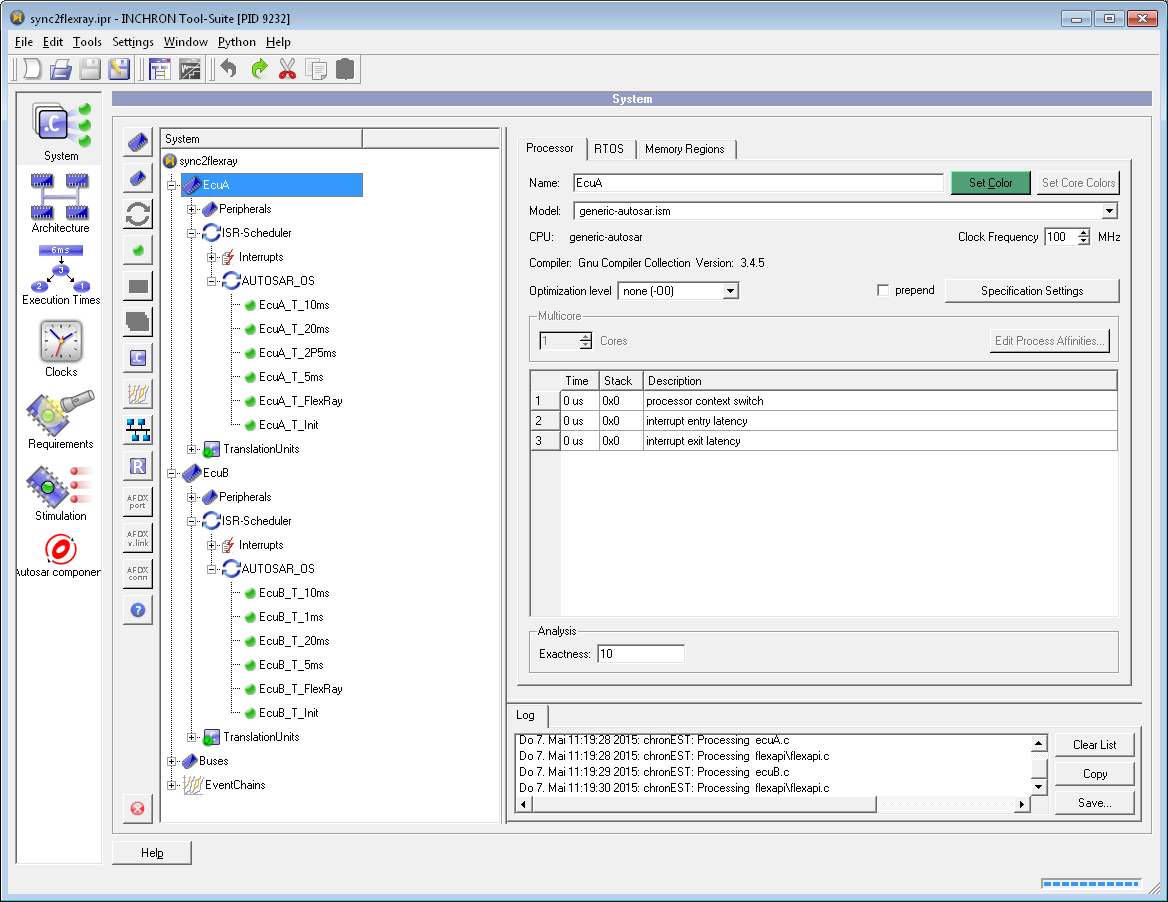

- 6.2 Module System

- 6.3 A typical system grouped by container elements, shown open and closed

- 6.4 Global Project Properties

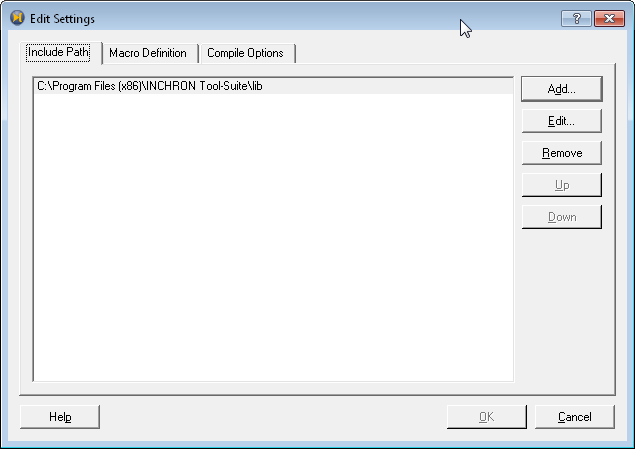

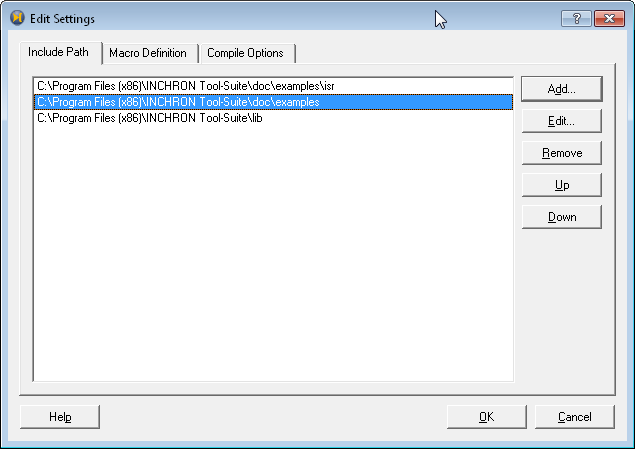

- 6.5 Include Path Settings

- 6.6 Global Includes

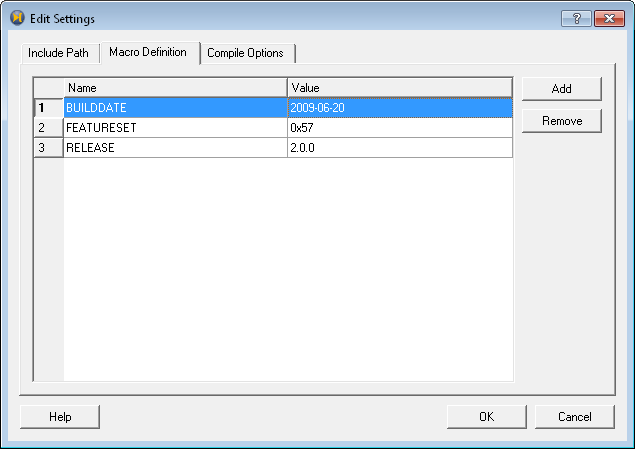

- 6.7 Global Macro Definitions

- 6.8 Compile Options

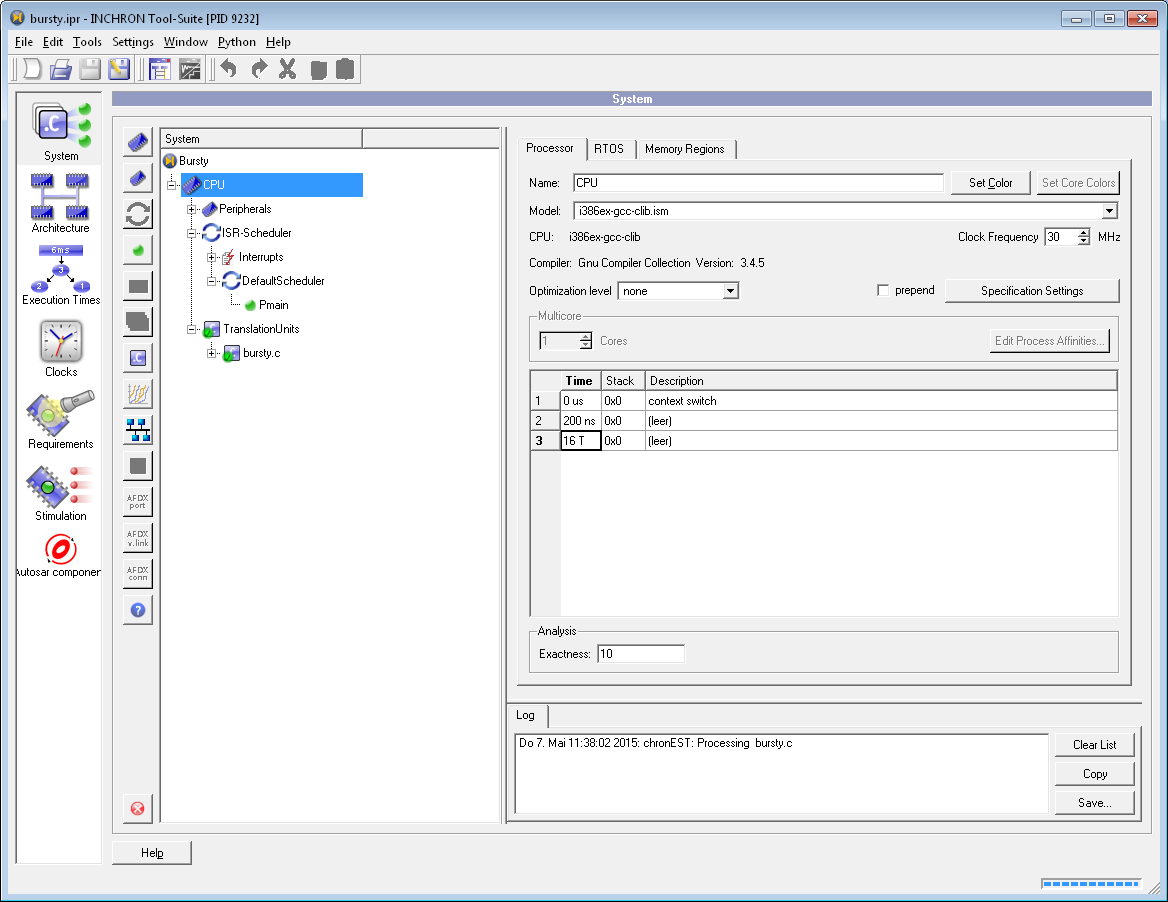

- 6.9 Microprocessor Properties

- 6.10 Edit Process Core Affinities Dialog

- 6.11 RTOS Properties

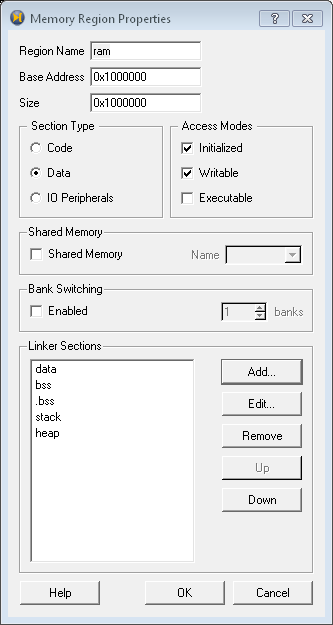

- 6.12 Memory Region Settings

- 6.13 Memory Region Properties Dialog

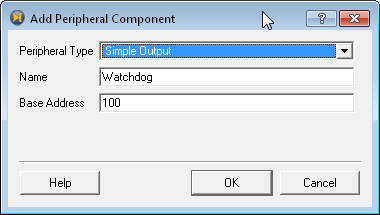

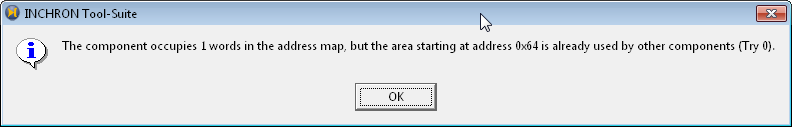

- 6.14 Selection of Peripherals

- 6.15 Error Message on Address Conflict

- 6.16 Message Properties

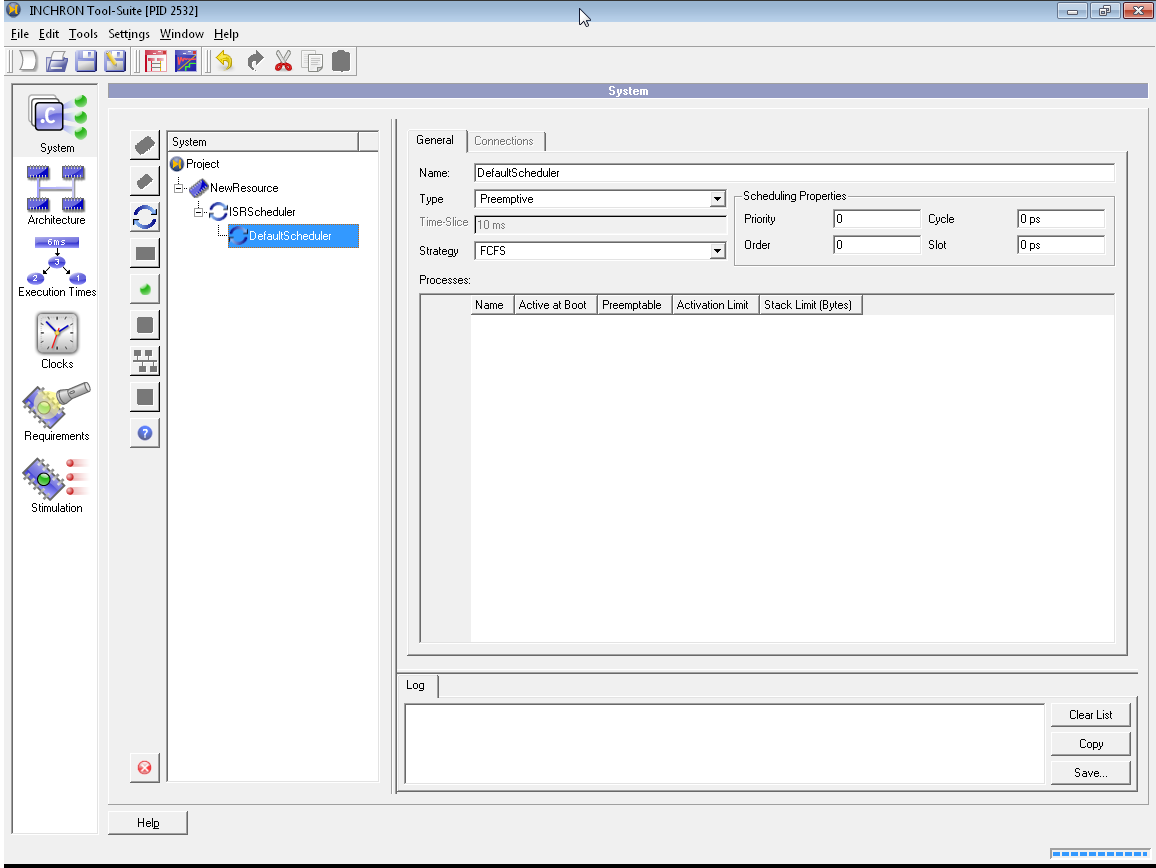

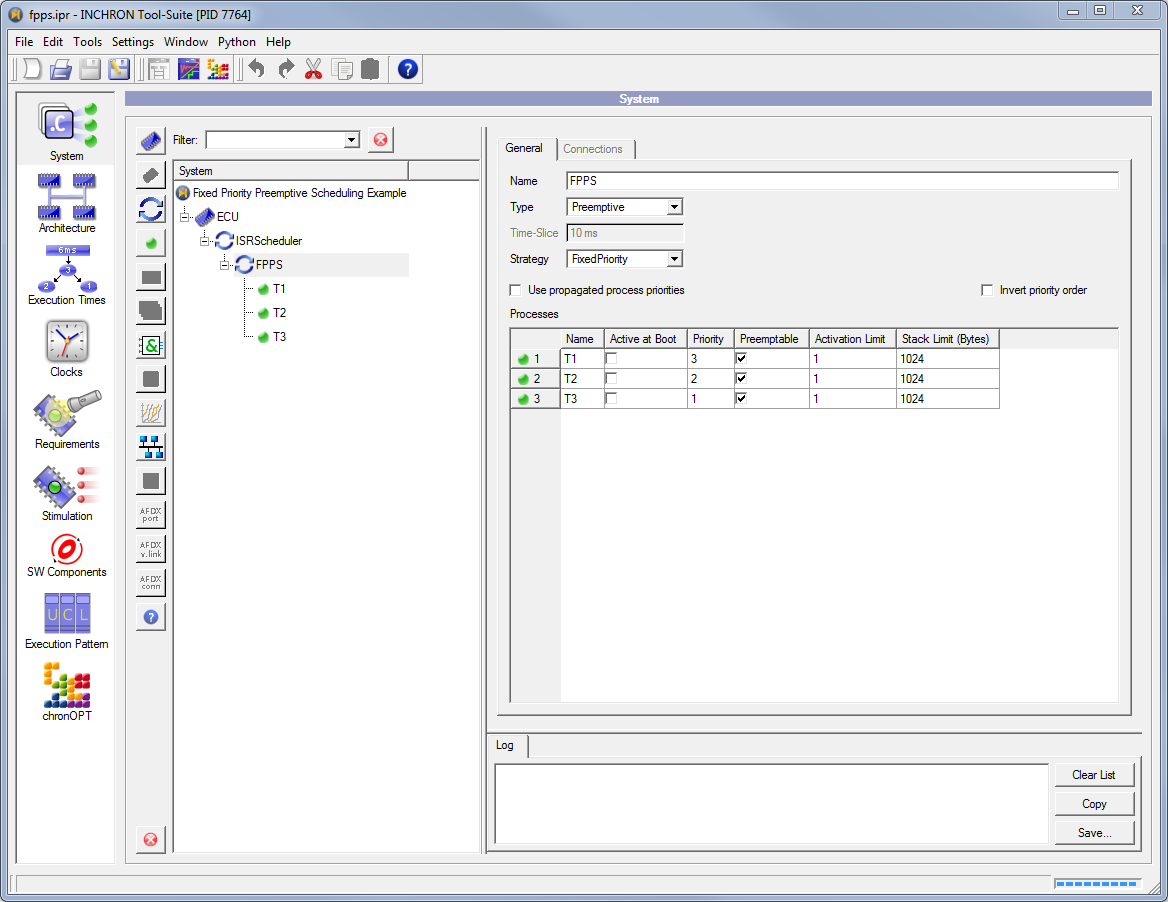

- 6.17 Scheduler Properties

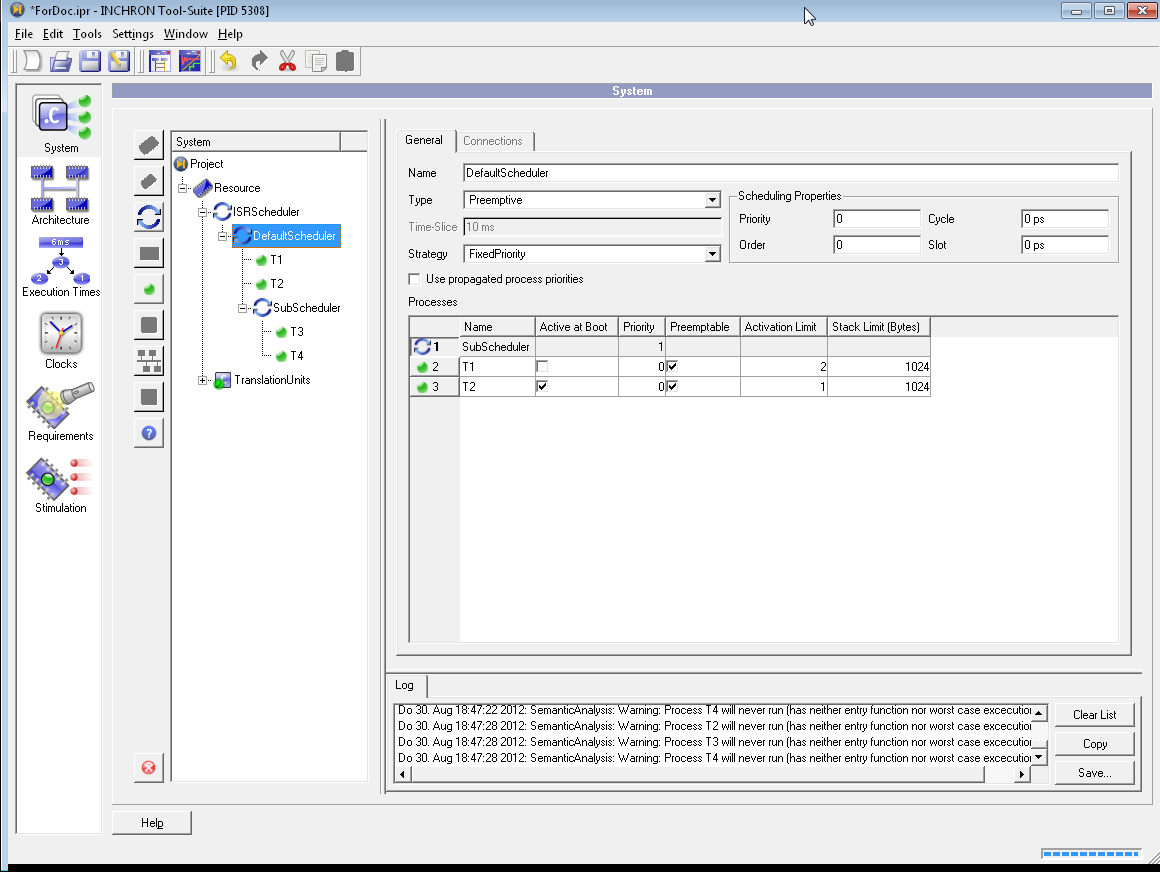

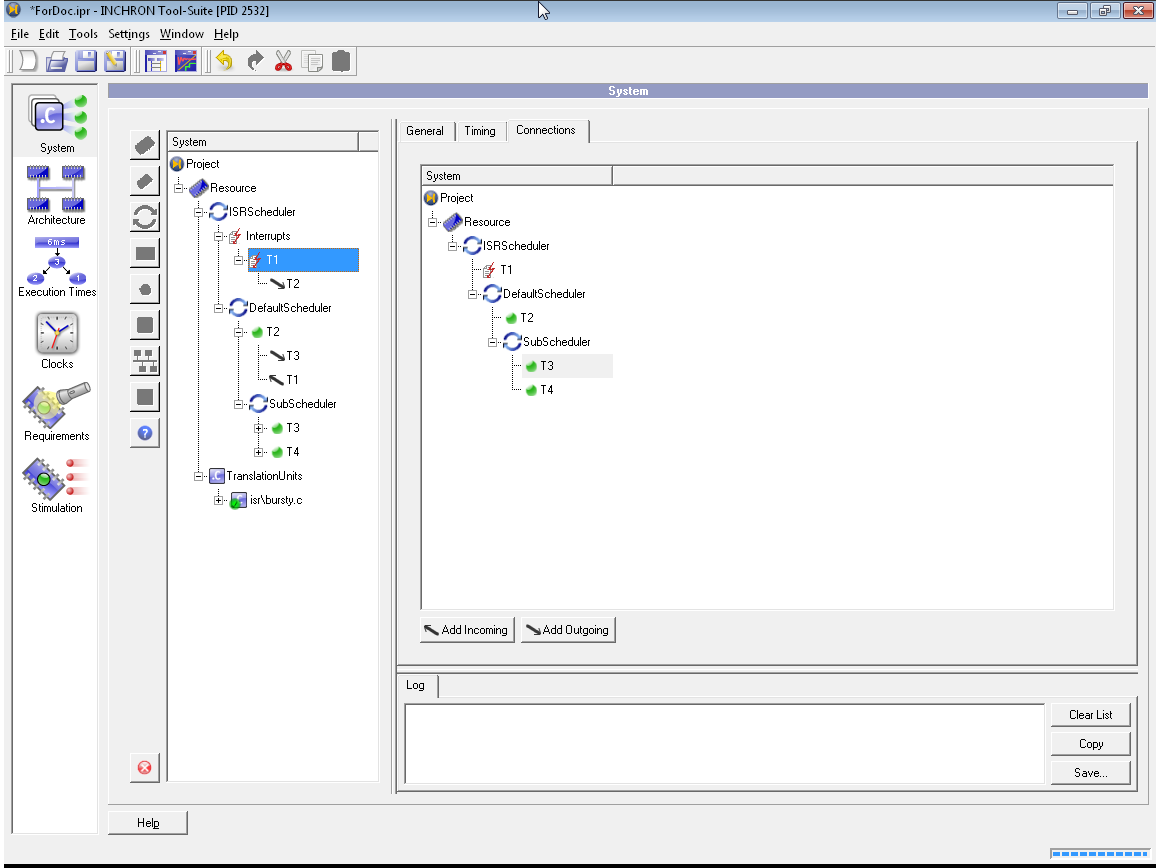

- 6.18 Scheduler with two processes and a sub-scheduler

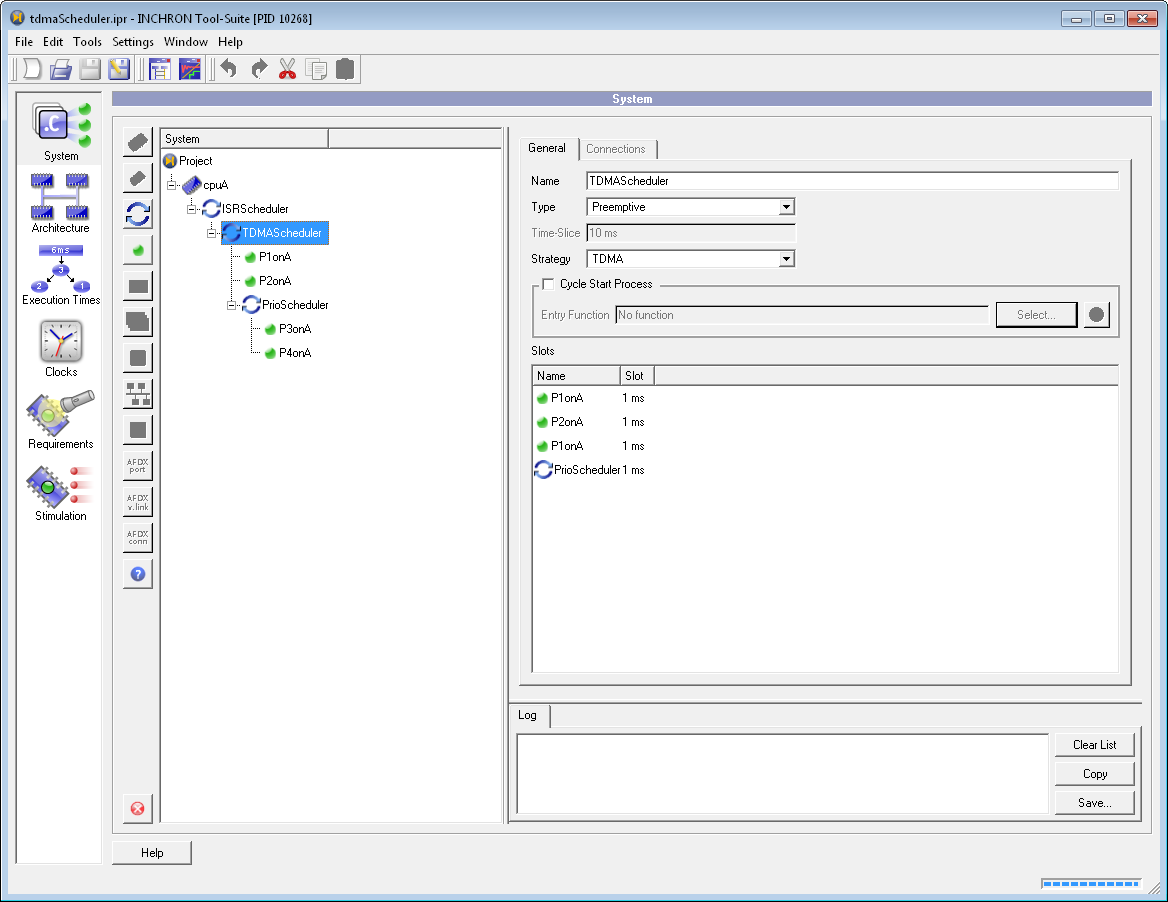

- 6.19 Property Widget of a TDMA Scheduler

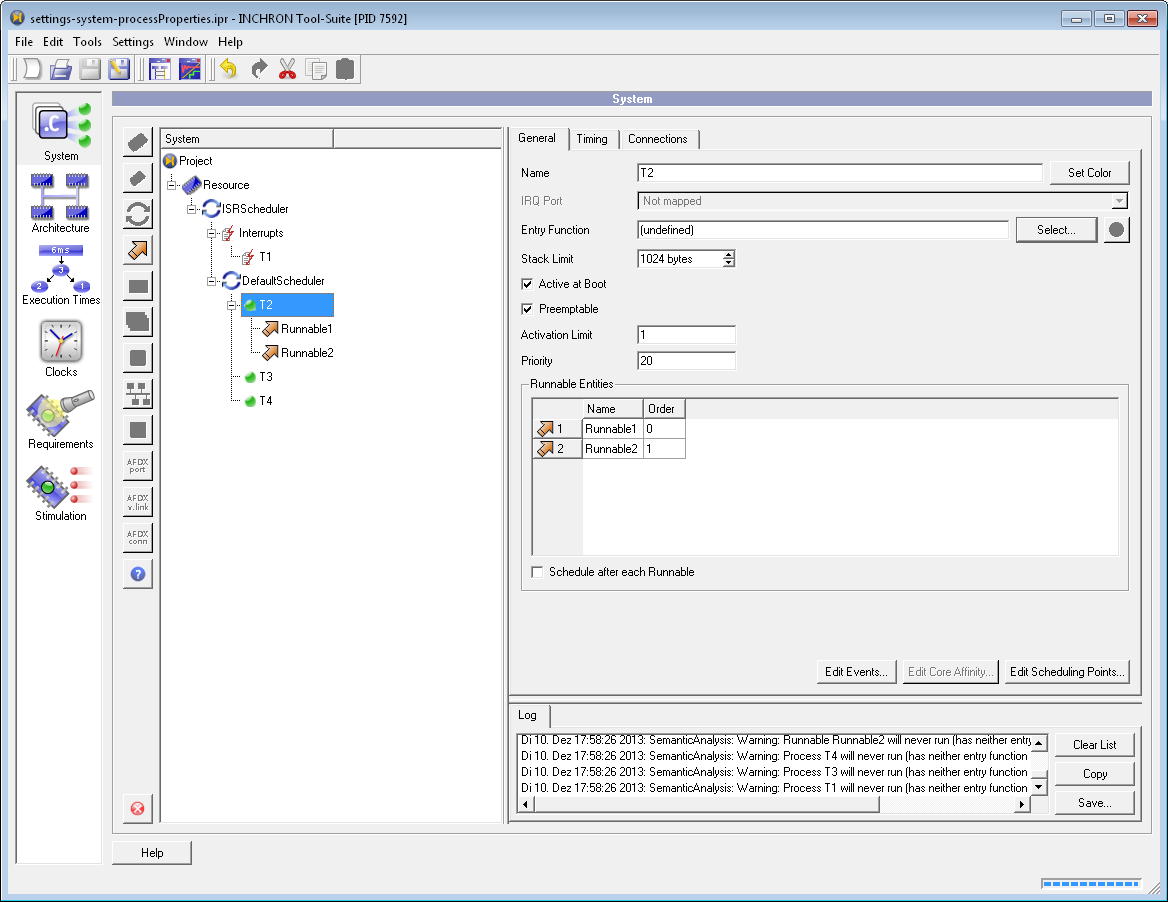

- 6.20 Process Properties

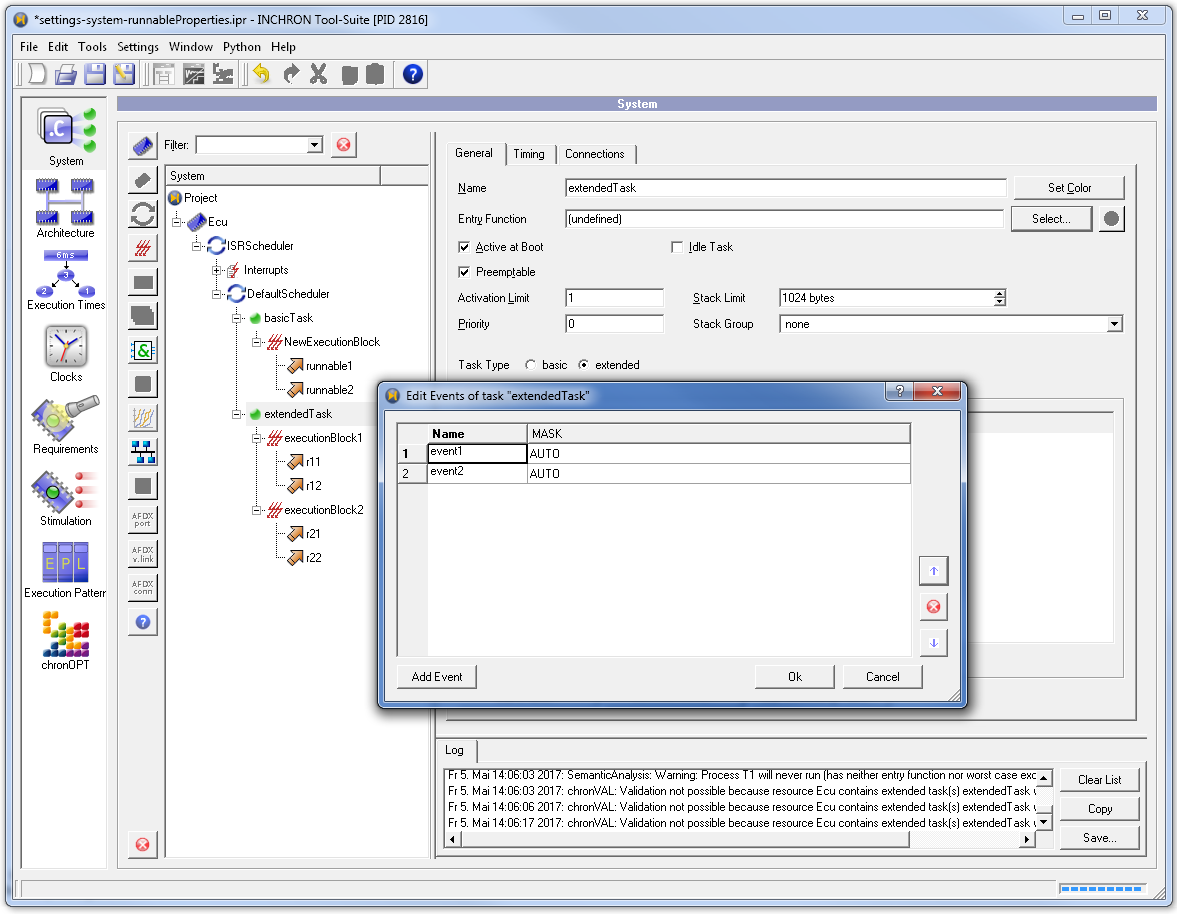

- 6.21 Edit Events Dialog for a task

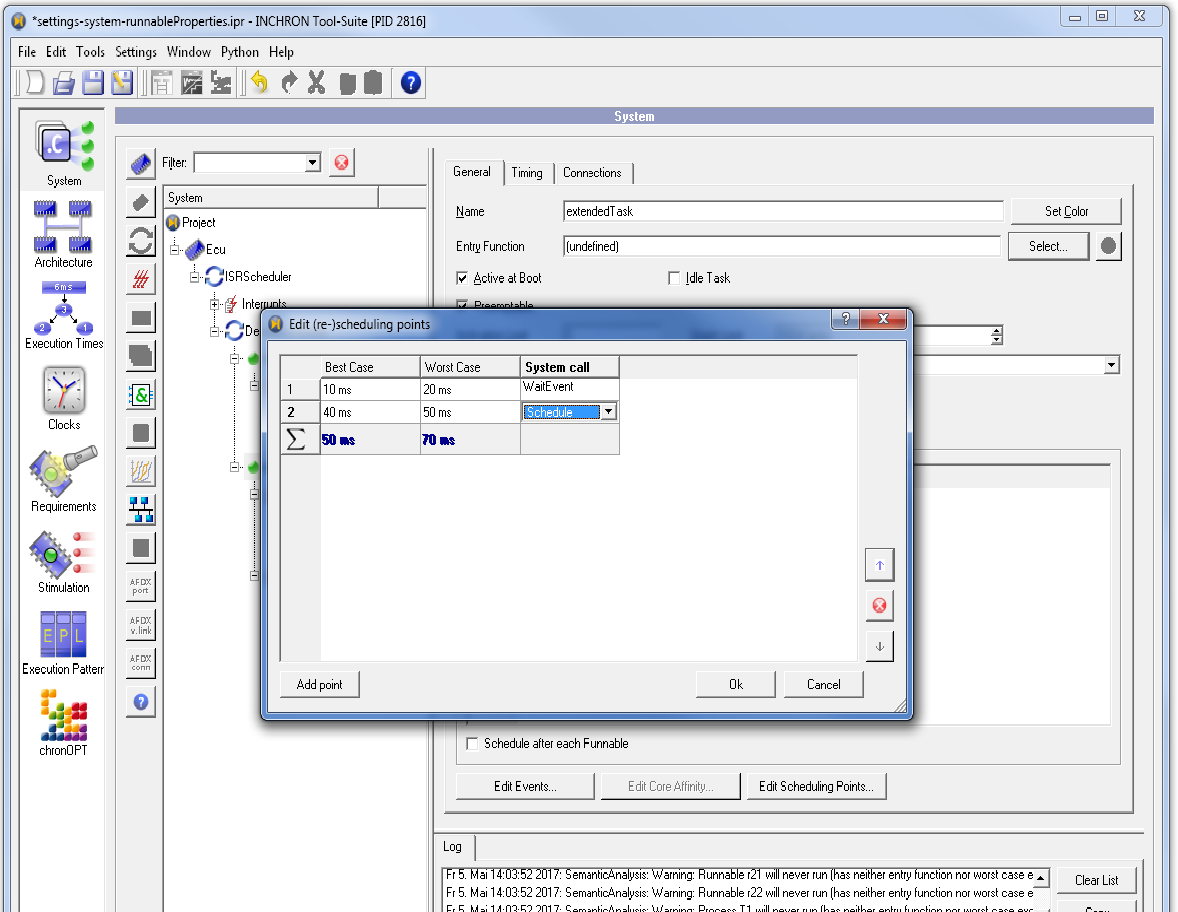

- 6.22 Edit Scheduling Points Dialog

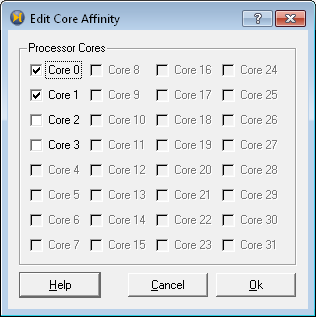

- 6.23 Edit Core Affinity Dialog

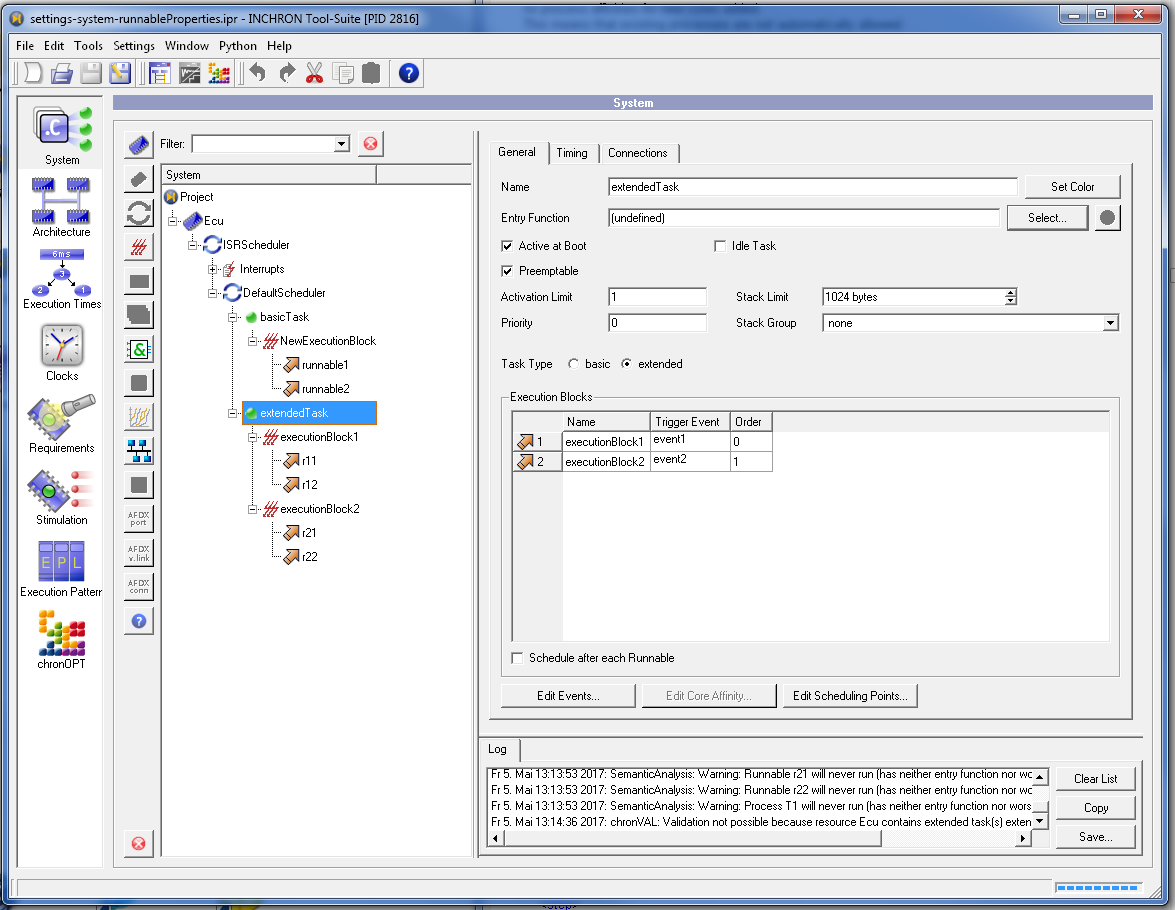

- 6.24 Extended Task with Two Execution Blocks

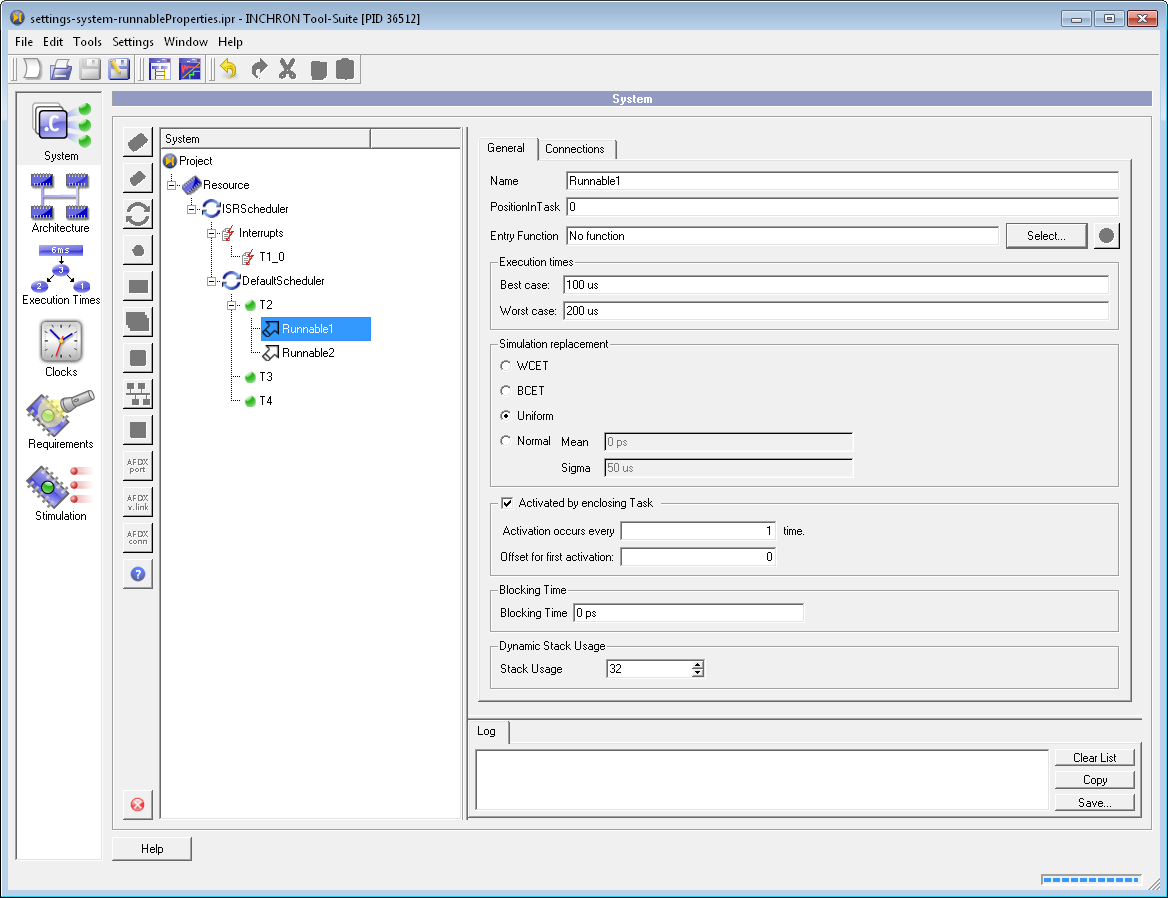

- 6.25 Runnable Properties

- 6.26 Process Dependencies

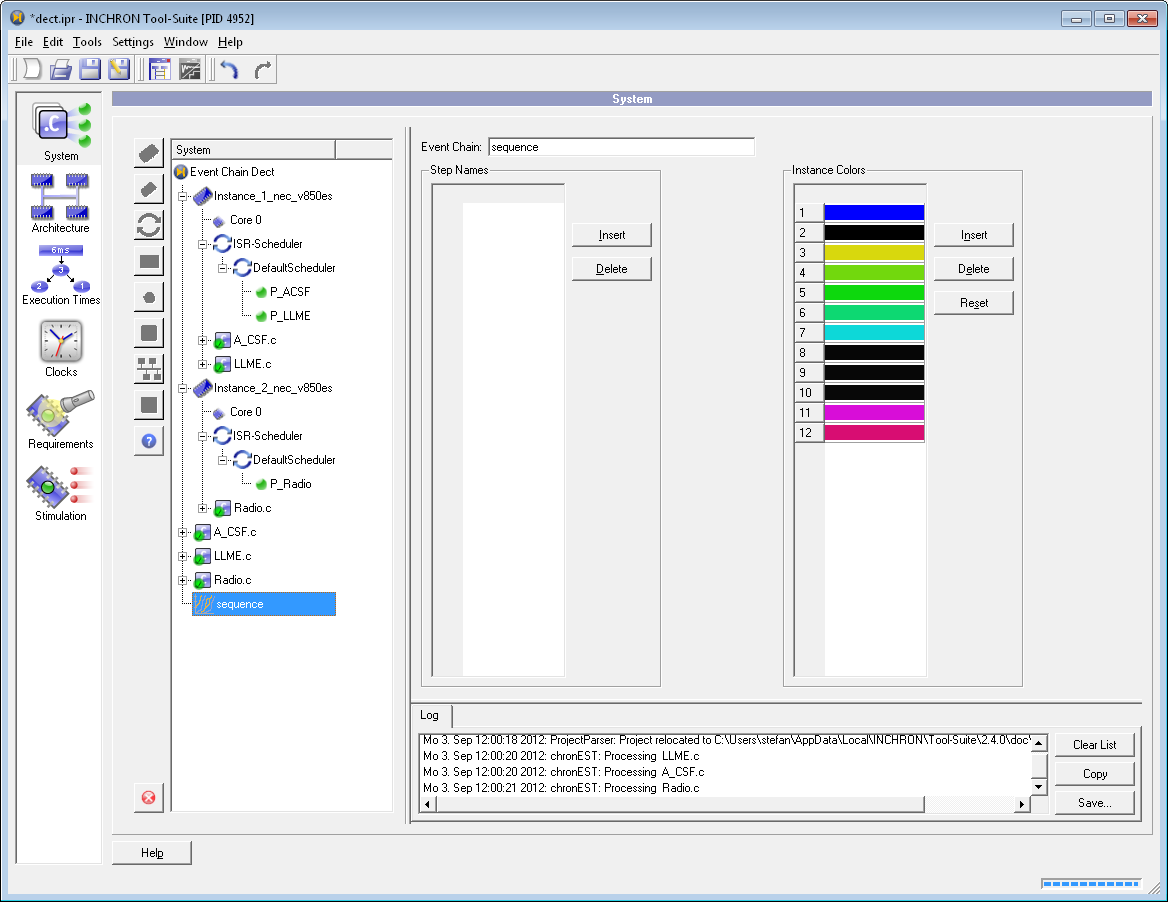

- 6.27 Event Chain Properties

- 6.28 Module Architecture With Rest Bus

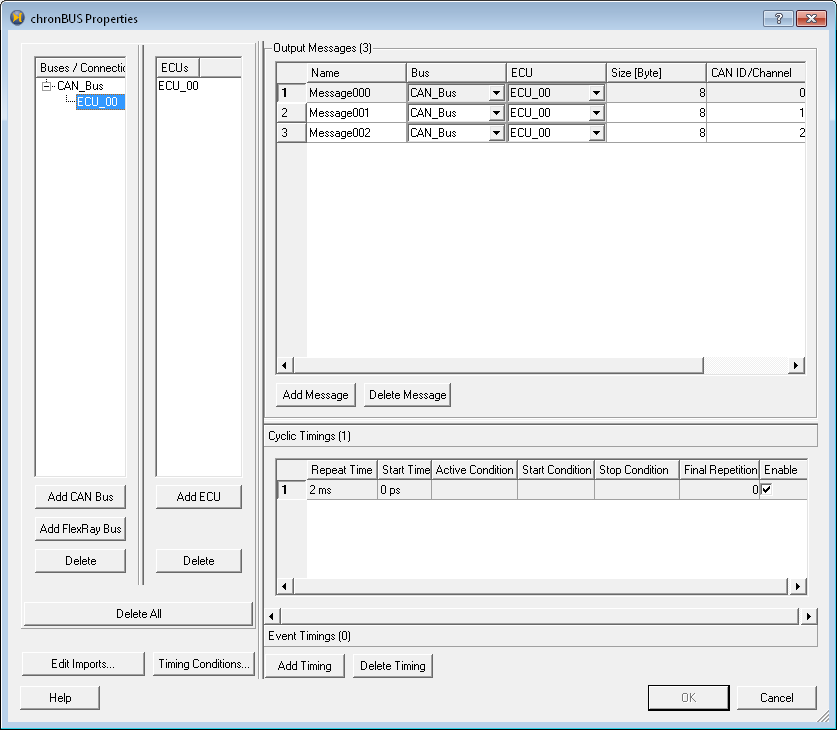

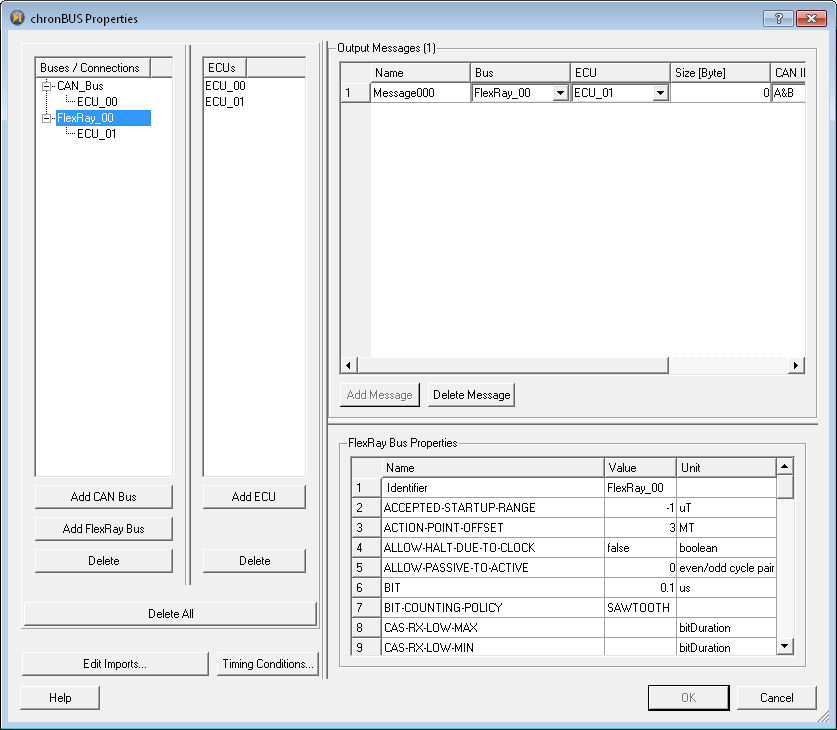

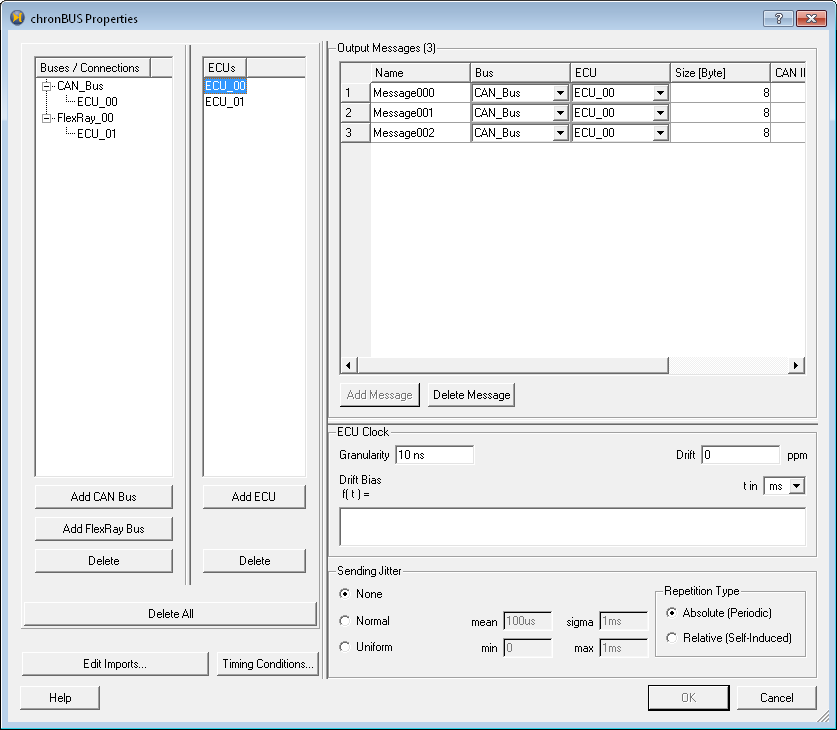

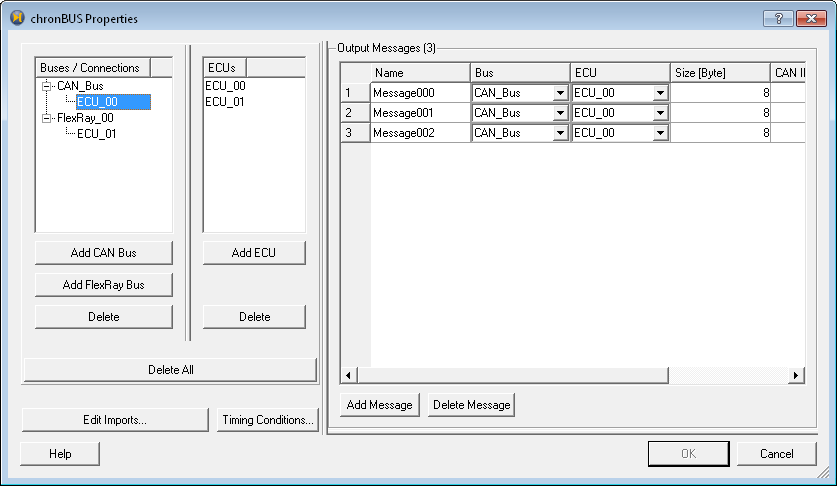

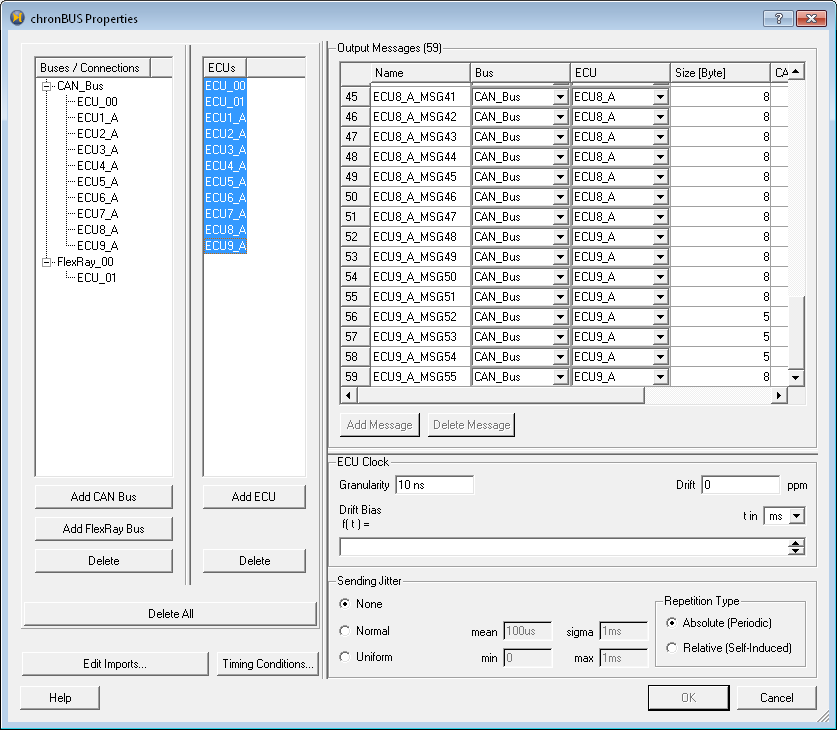

- 6.29 Rest Bus Configuration Dialog

- 6.30 Rest Bus - Bus Properties

- 6.31 Rest Bus - ECU Properties

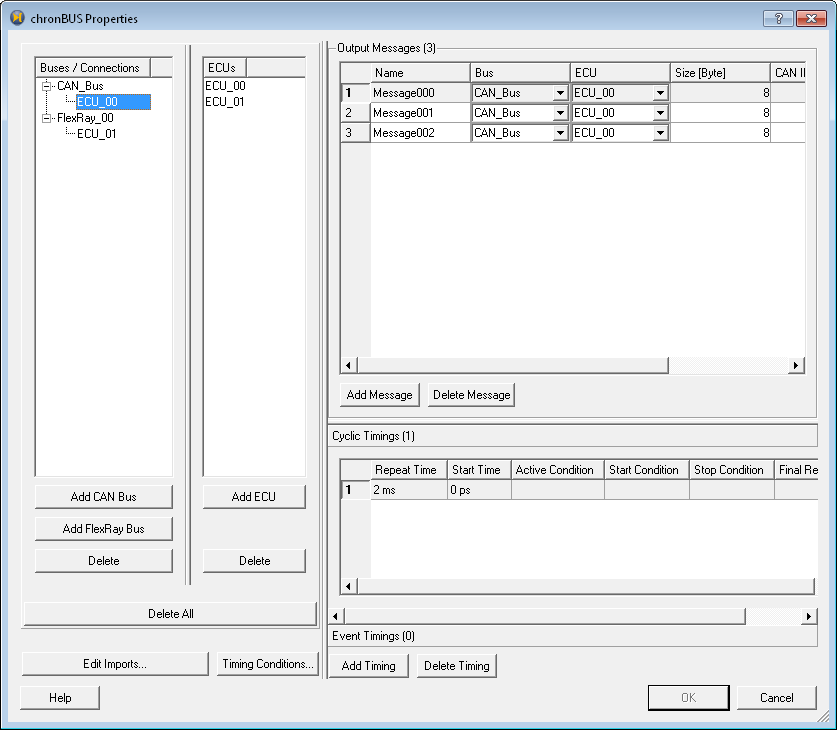

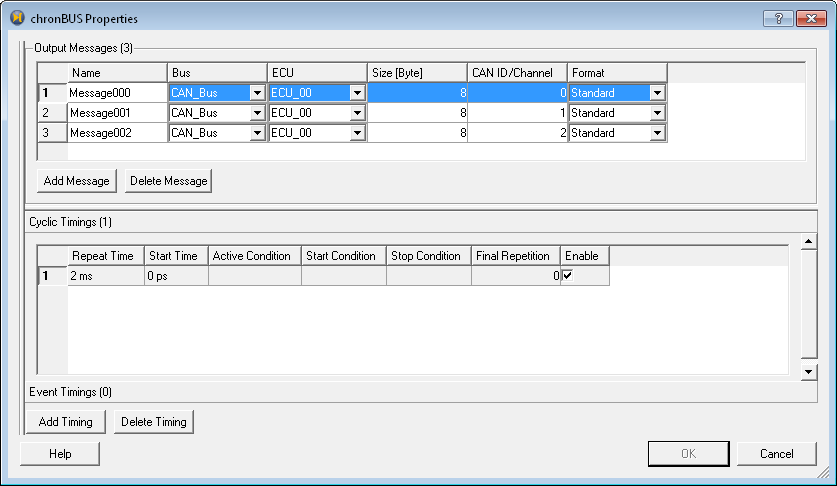

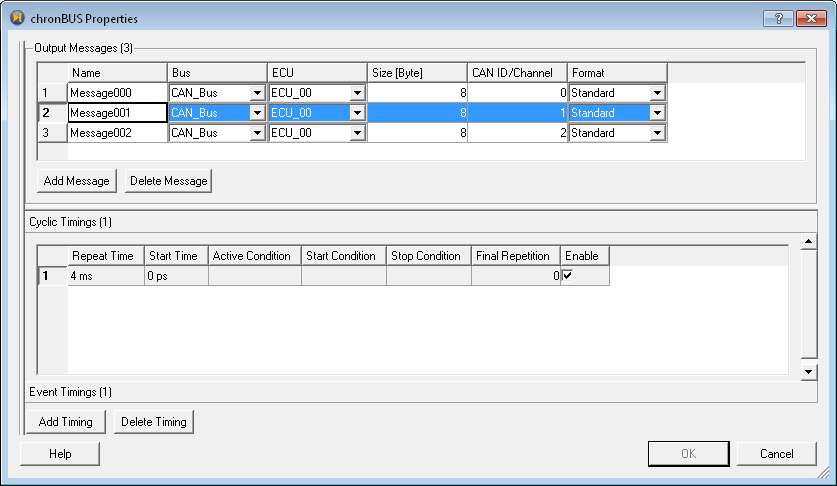

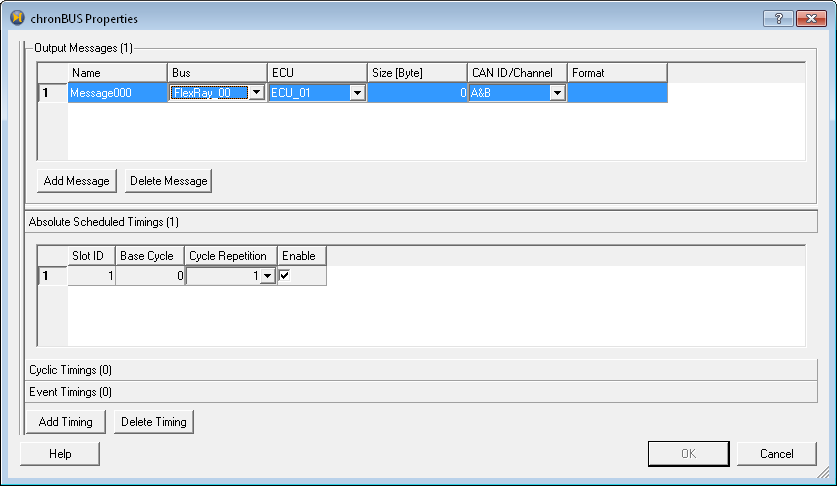

- 6.32 Output-Messages Table

- 6.33 Cyclic Timings Table

- 6.34 Event Timing-table

- 6.35 Absolute Scheduling Timing Table

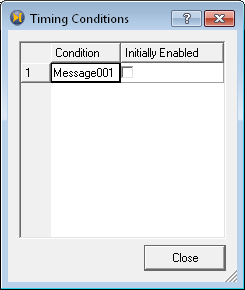

- 6.36 Timing Condition Dialog

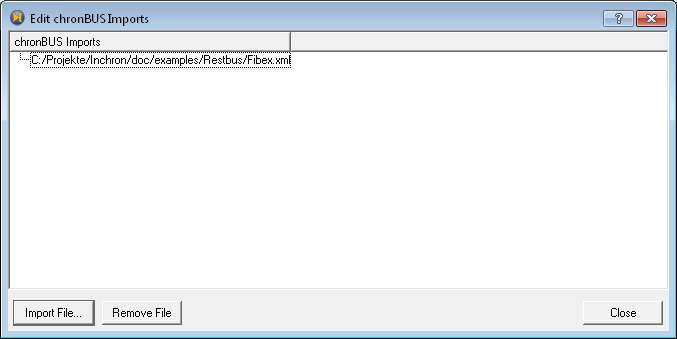

- 6.37 List of Imports

- 6.38 Rest Bus Model

- 6.39 State Diagram

- 6.40 Load Diagram

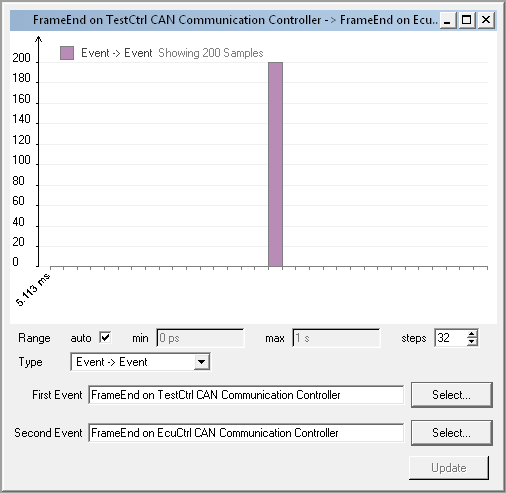

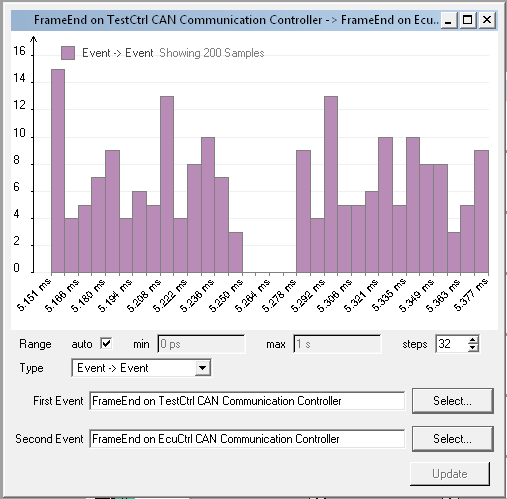

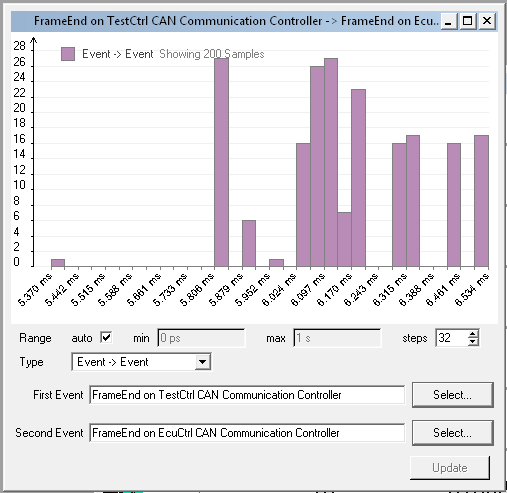

- 6.41 Histogram: Latencies without and with Rest Bus

- 6.42 Histogram: Latencies After FIBEX Import

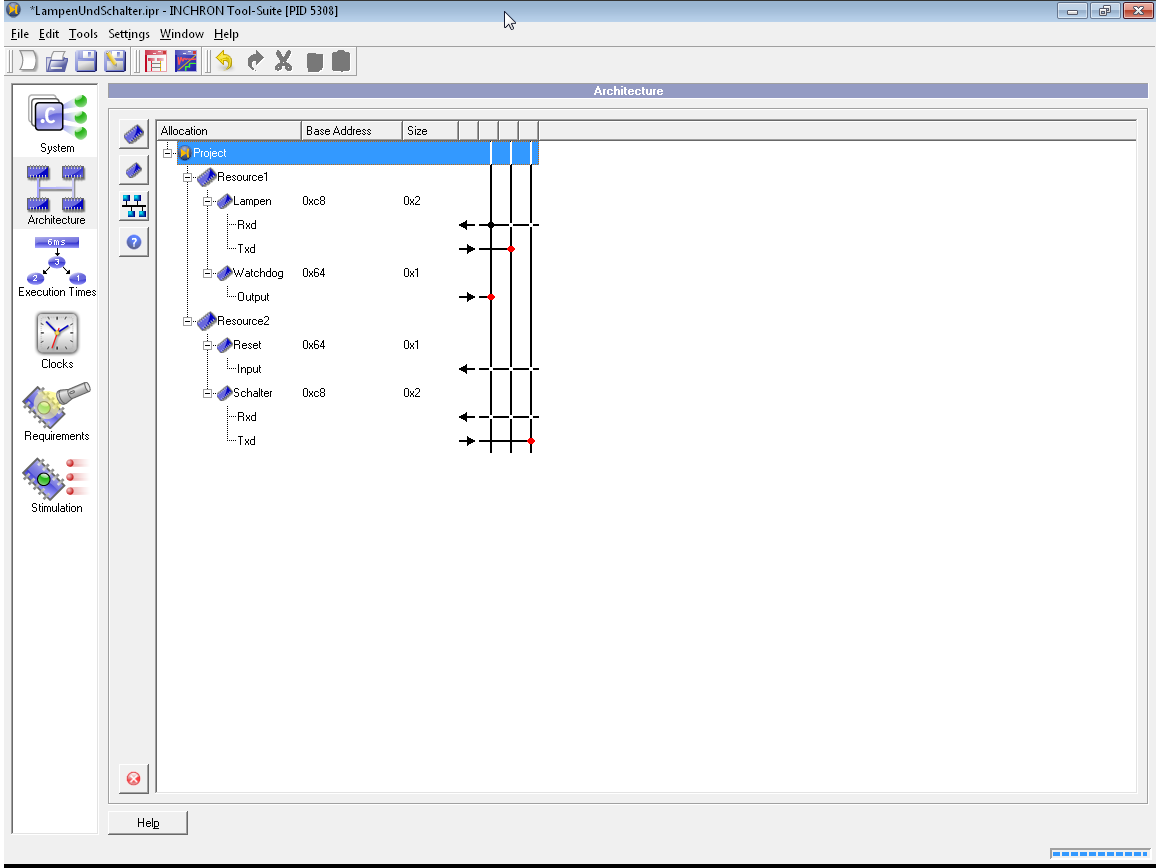

- 6.43 Architecture View with Port Connection Matrix

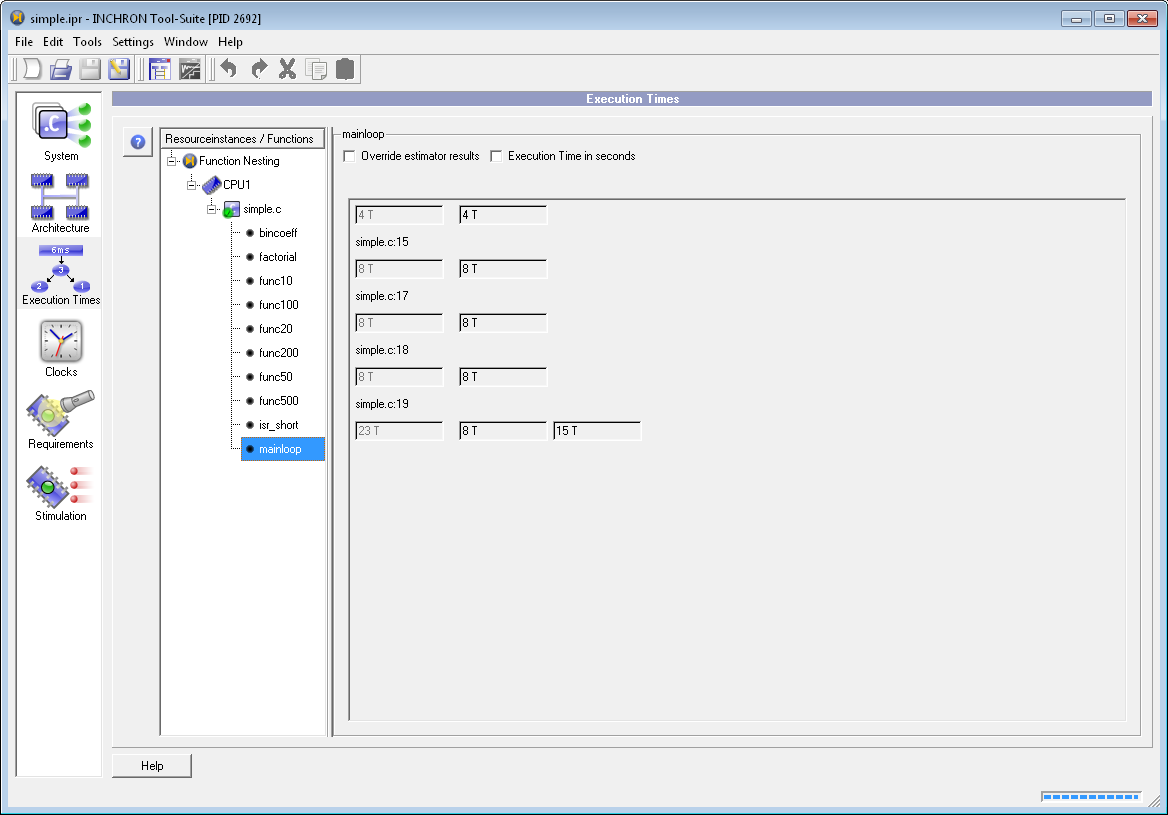

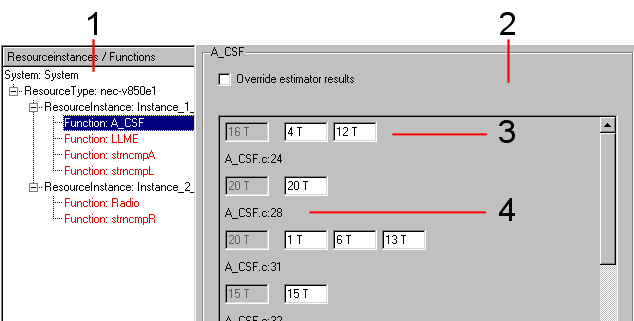

- 6.44 Module Execution Time

- 6.45 Module Execution Time

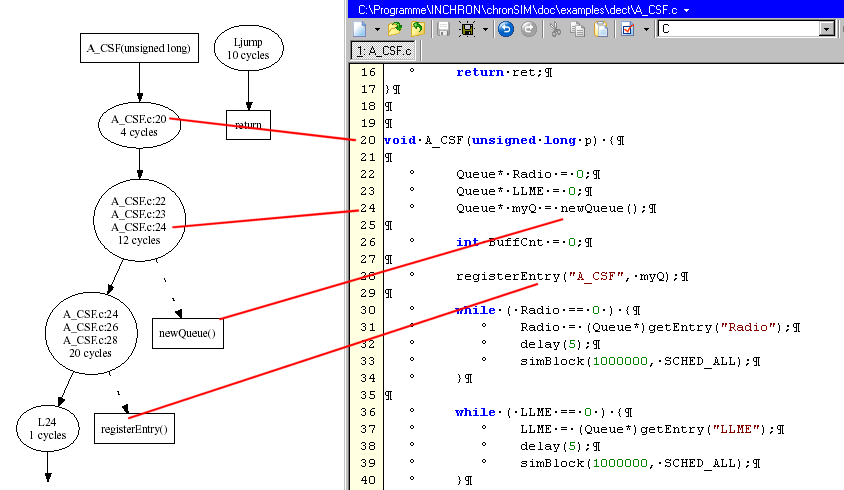

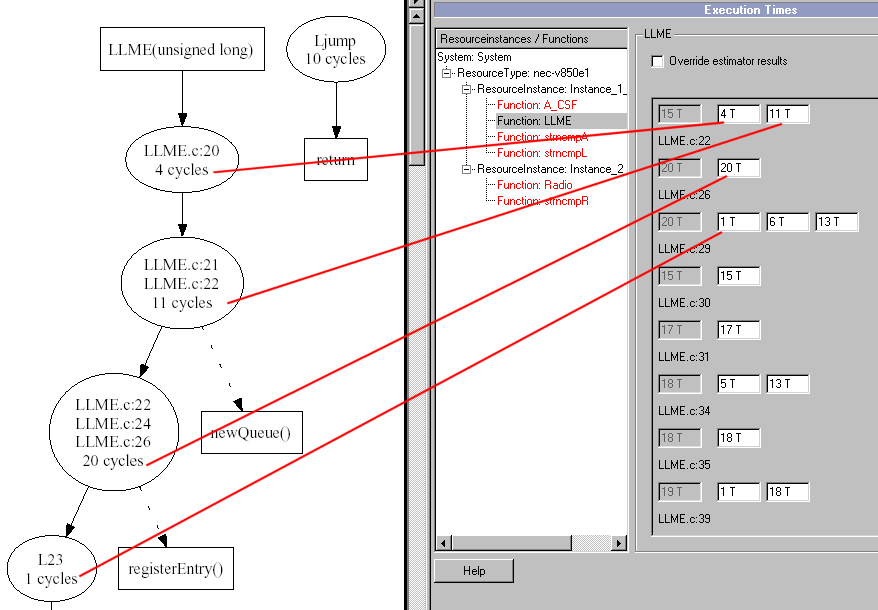

- 6.46 Control Flow Graph Nodes and Corresponding Source Code Basic Blocks

- 6.47 Control Flow Graph Nodes and corresponding Execution Times

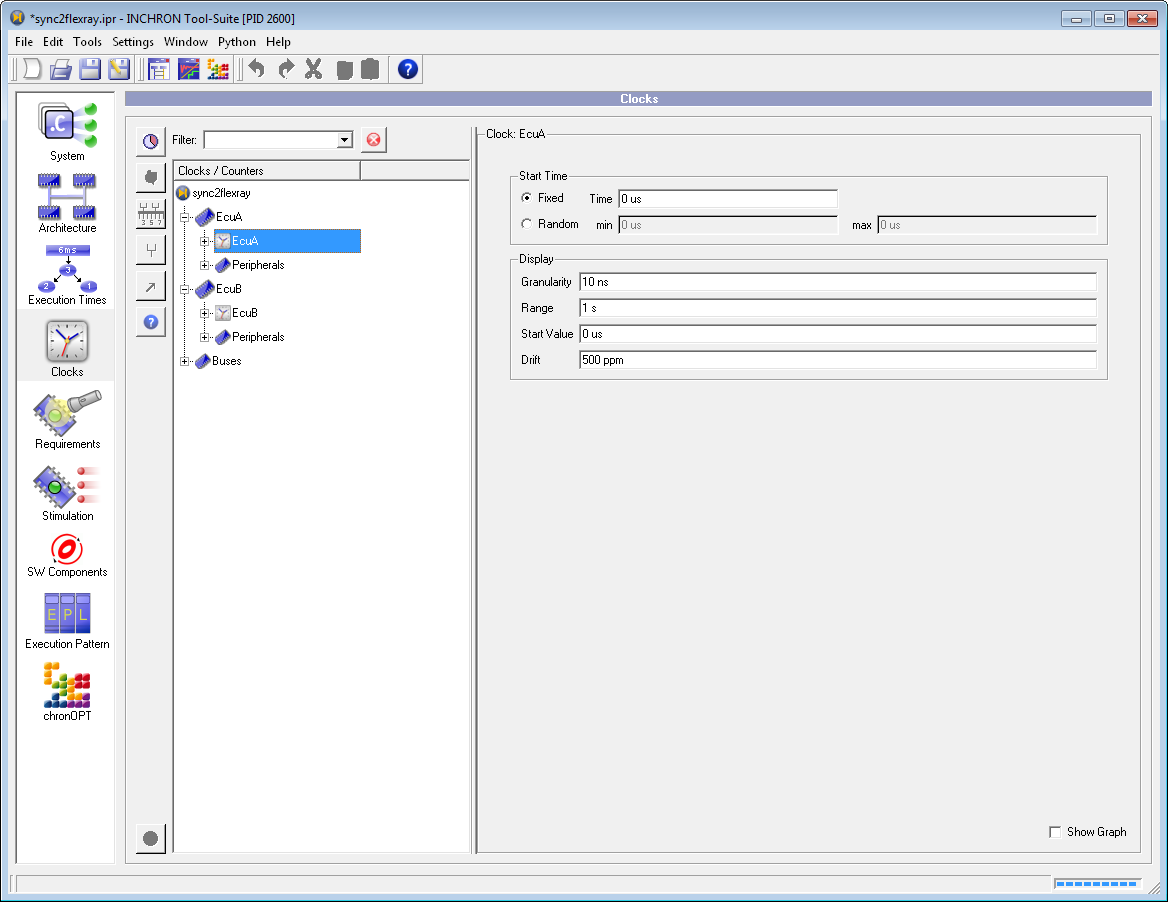

- 6.48 Module Clocks

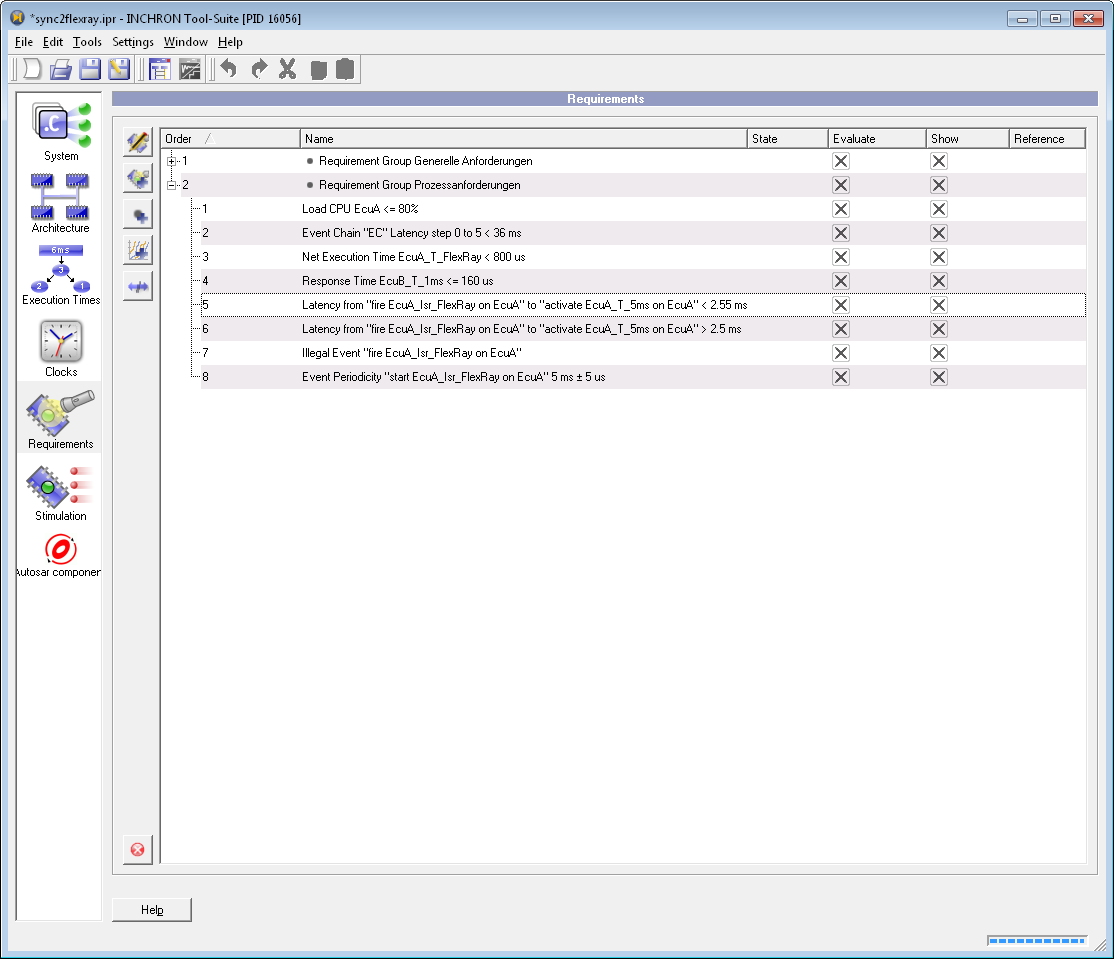

- 6.49 Module Requirements

- 6.50 Process Net Execution Time Requirement

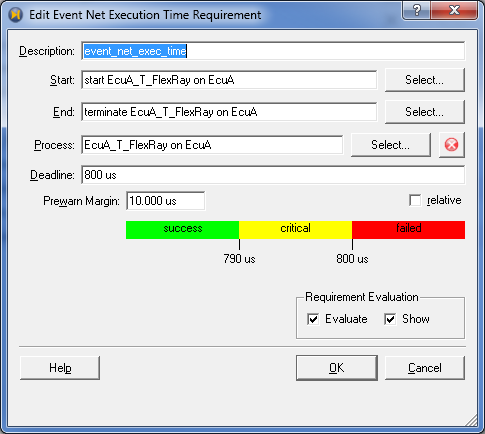

- 6.51 Event Net Execution Time Requirement

- 6.52 Net Slack Time Requirement

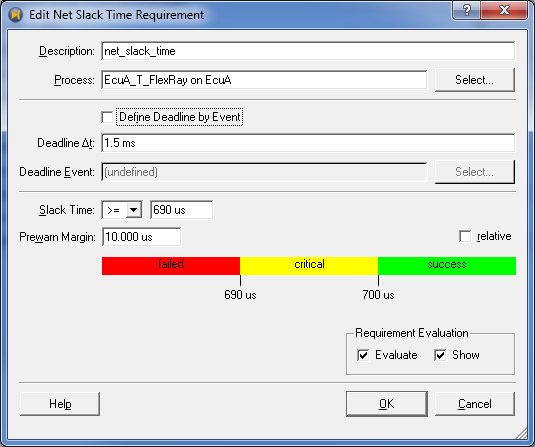

- 6.53 Response Time Requirement

- 6.54 Event Timing Requirement

- 6.55 Object Selection Dialog - unfiltered versus filtered event tree

- 6.56 Illegal Event Requirement

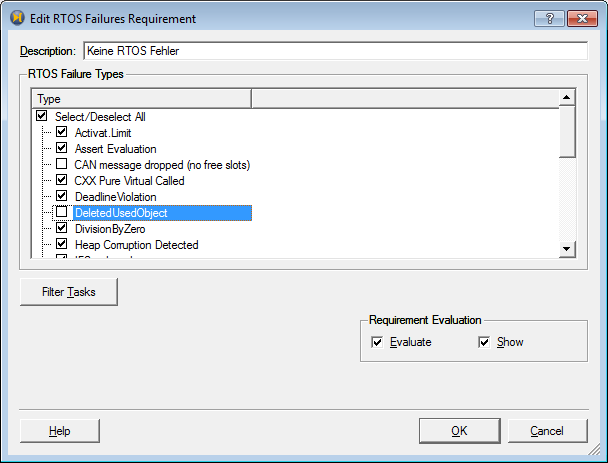

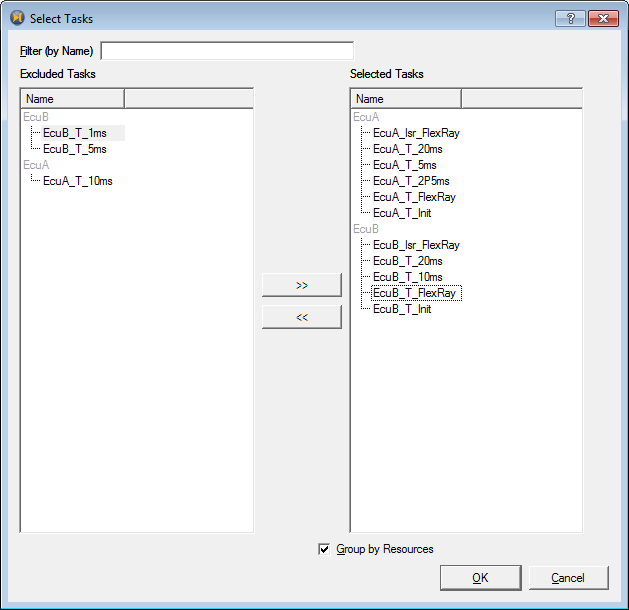

- 6.57 RTOS Failure Requirement - type selection

- 6.58 RTOS Failure Requirement - task selection

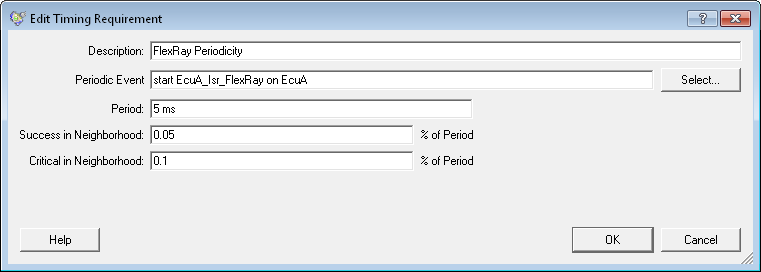

- 6.59 Event Periodicity Requirement

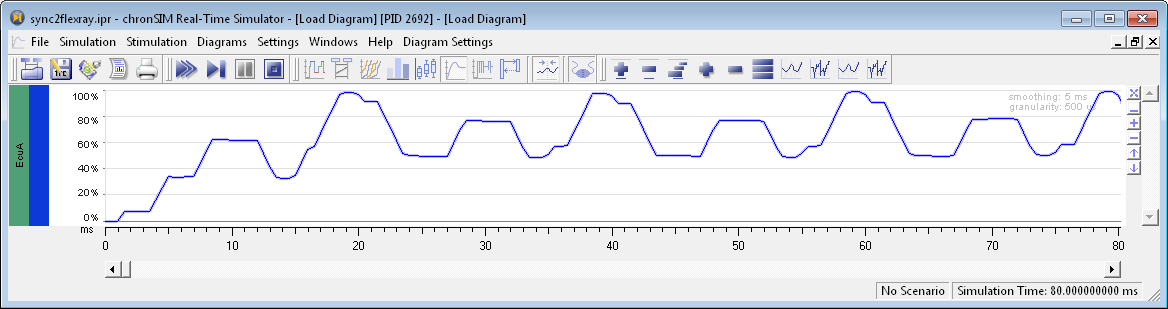

- 6.60 Load Diagram

- 6.61 Load Requirement

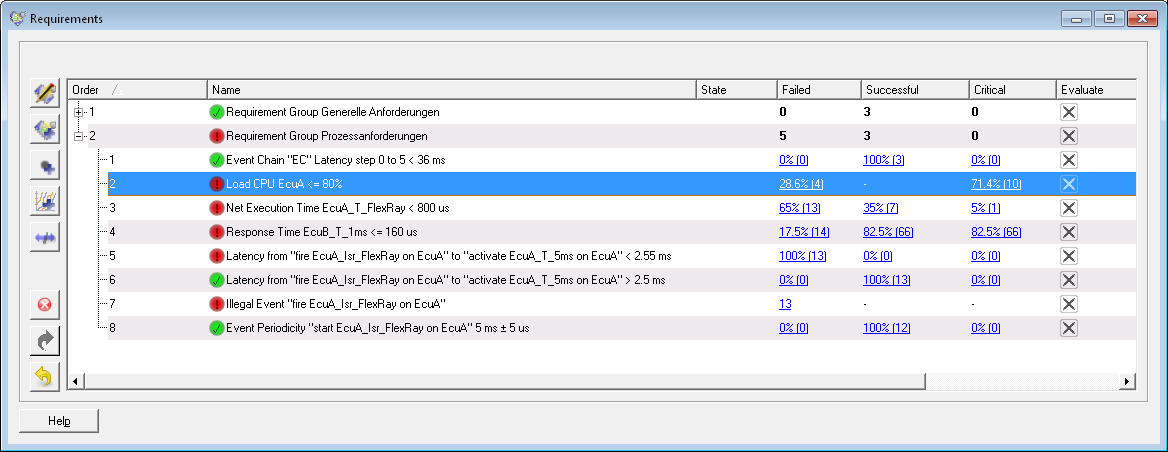

- 6.62 Requirements Overview

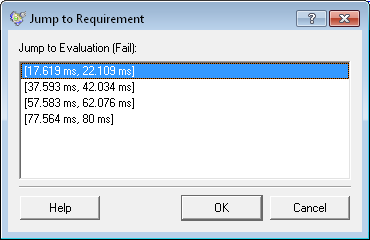

- 6.63 Load Requirement Evaluations

- 6.64 Event Chain Timing Requirement

- 6.65 Module Stimulation

- 6.66 Add Stimulation Scenario Dialog

- 6.67 Tab Target

- 6.68 Tab Generator

- 6.69 Stimulation from Random Generators

- 6.70 Absolute Periodic Stimulation

- 6.71 Absolute periodic Stimulation With Normal Distribution

- 6.72 Absolute Periodic Stimulation With Uniform Distribution

- 6.73 Selecting a CSV file

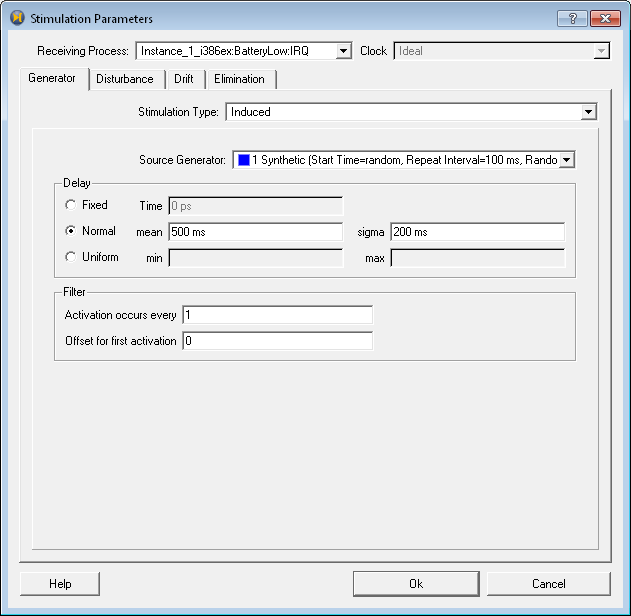

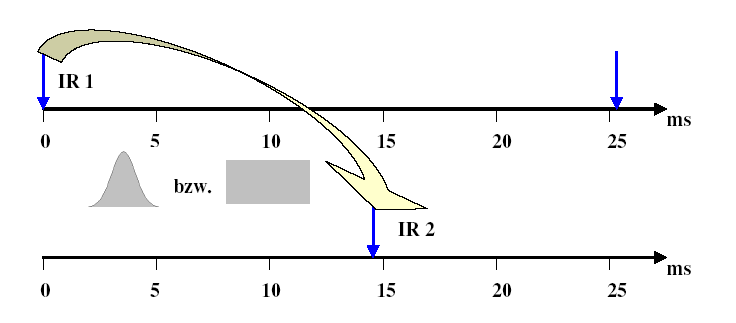

- 6.74 Induced Stimulation Scheme

- 6.75 Induced Stimulation With Normal or Uniform Delay

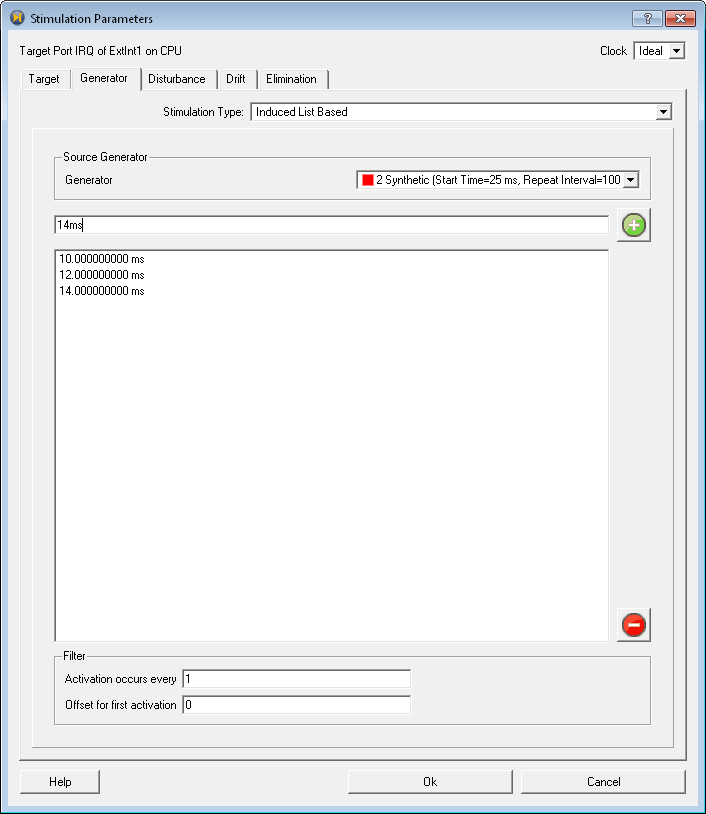

- 6.76 Induced List Based Generator

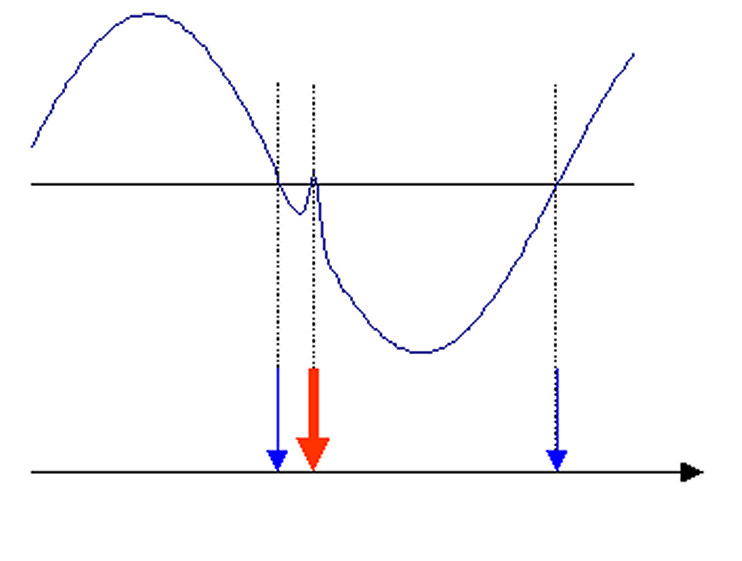

- 6.77 Example of Causal Stimulation Disturbance

- 6.78 Disturbance Parameters Dialog

- 6.79 Drift Parameters Dialog

- 6.80 Drift of a Stimulation

- 6.81 The Stimulation Parameters Dialog for a burst filter.

- 6.82 Scenario Preview

- 6.83 Stimuli Preview of a Scenario

- 6.84 The Composite Scenario Dialog with a new composite scenario.

- 6.85 The Composite Scenario Dialog showing a composite scenario.

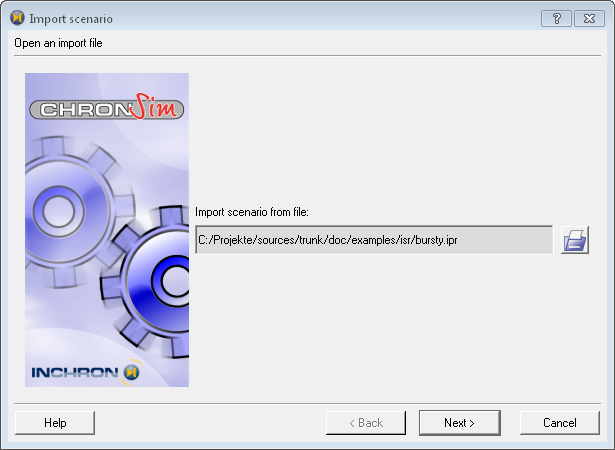

- 6.86 Initial Page of the Scenario Import Wizard

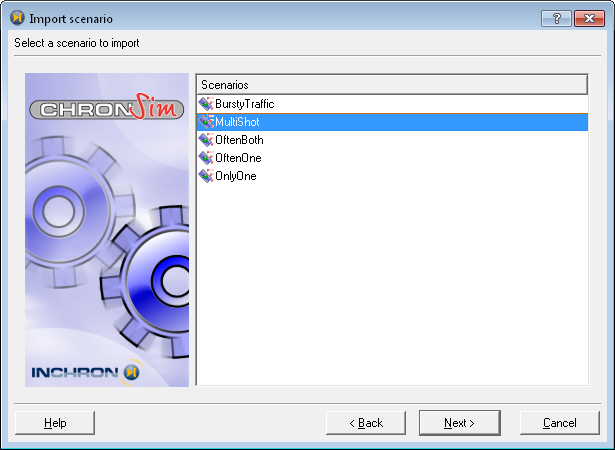

- 6.87 List of Importable Scenarios

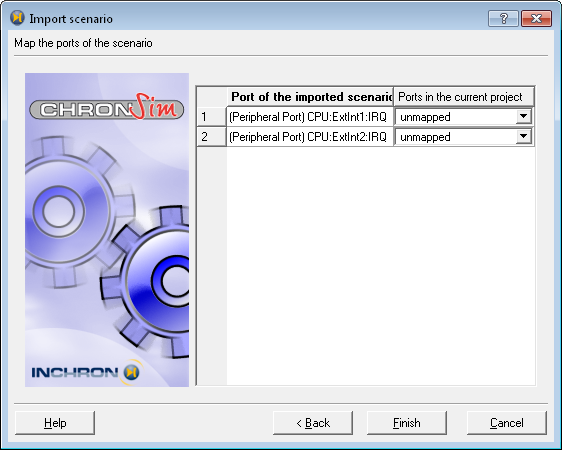

- 6.88 Mapping of Scenarios to Ports and Processes

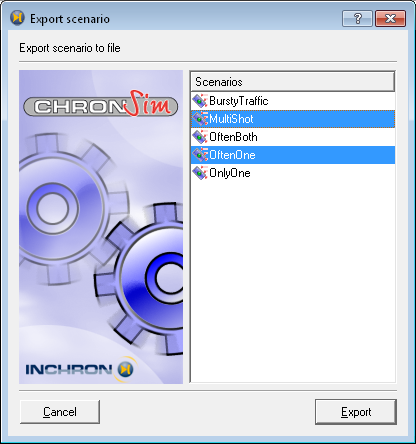

- 6.89 Scenario Export Dialog

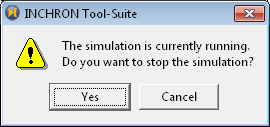

- 7.1 Warning in case of running simulation

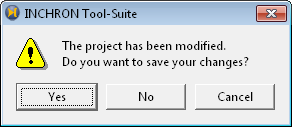

- 7.2 Warning in case of modified project

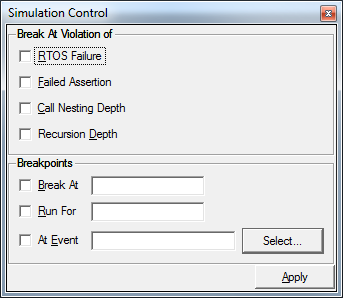

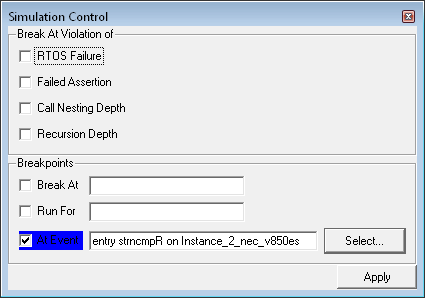

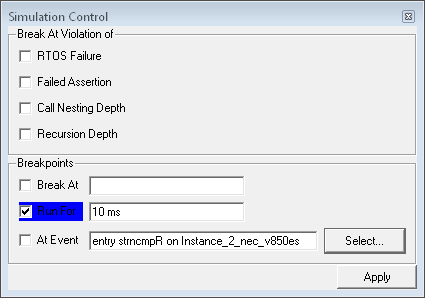

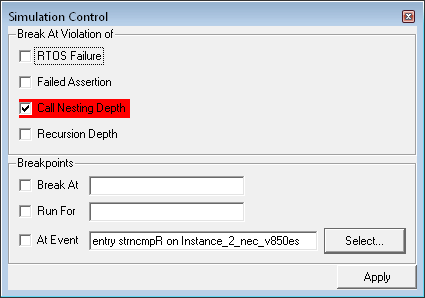

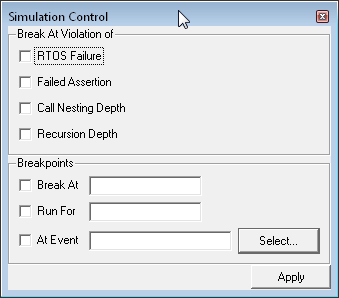

- 7.3 Simulation Control Window

- 7.4 Simulation stopped by breakpoint

- 7.5 Simulation Stop Due to Requirement Violation

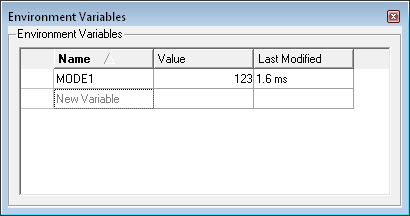

- 7.6 The Environment Variables Window

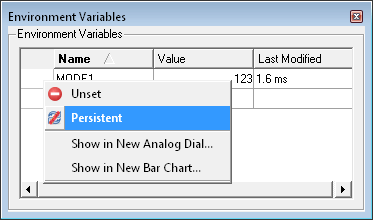

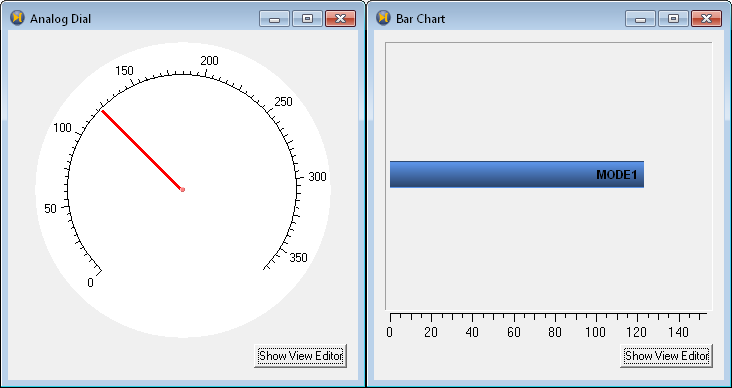

- 7.7 Persistent and non-persistent Environment Variables

- 7.8 Persistent and non-persistent Environment Variables

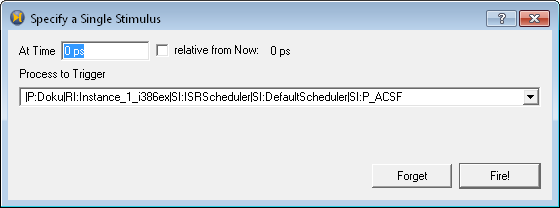

- 7.9 Single stimulation Settings

- 7.10 Loading a Scenario

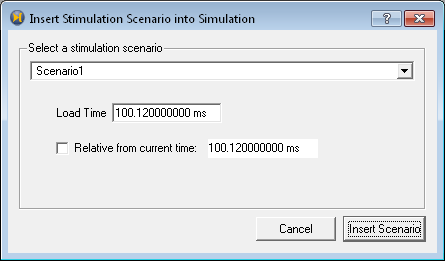

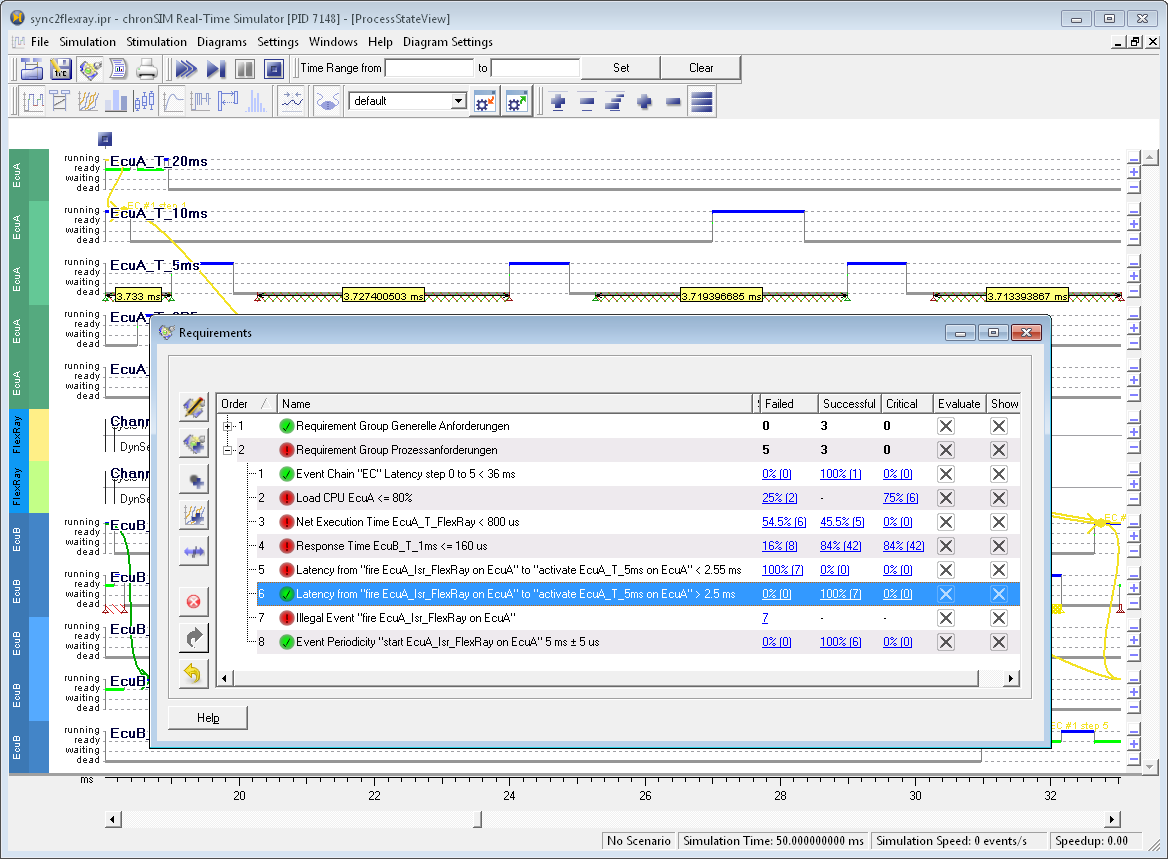

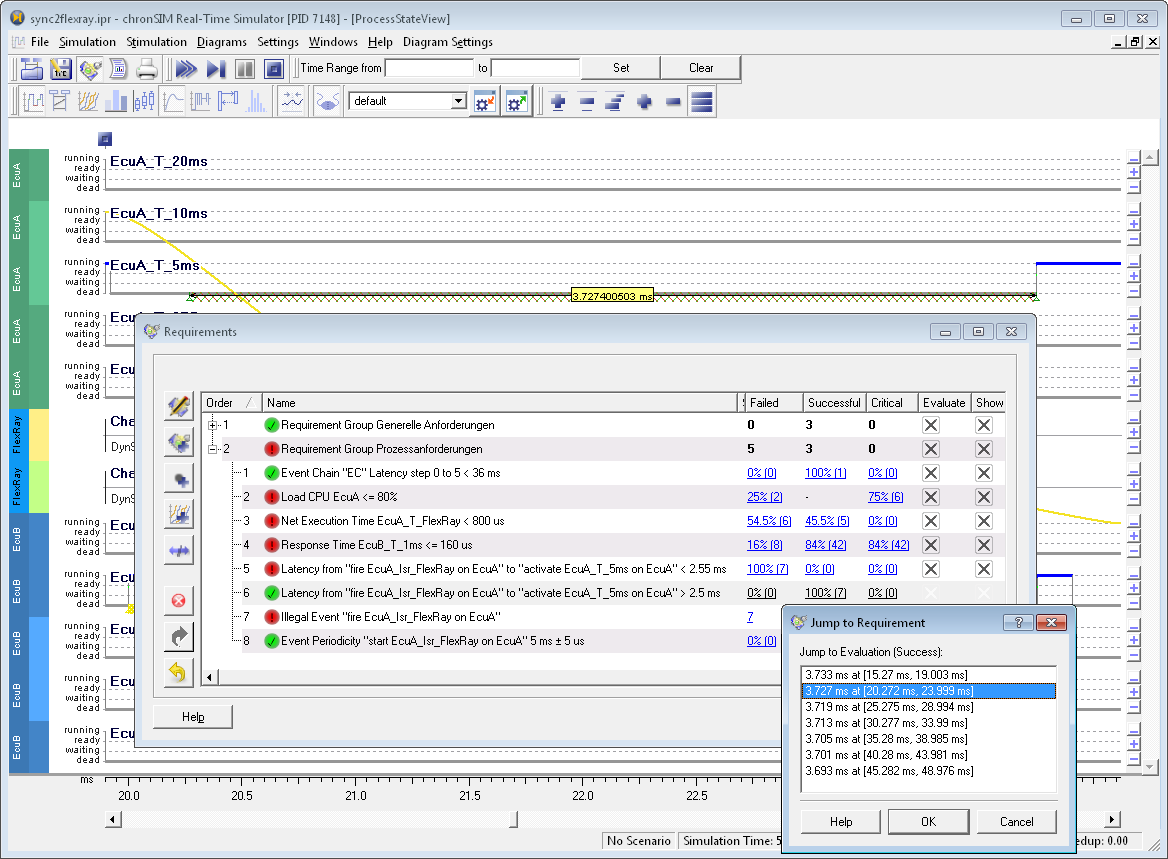

- 7.11 Overview Requirement Evaluation

- 7.12 List of Requirement Evaluations

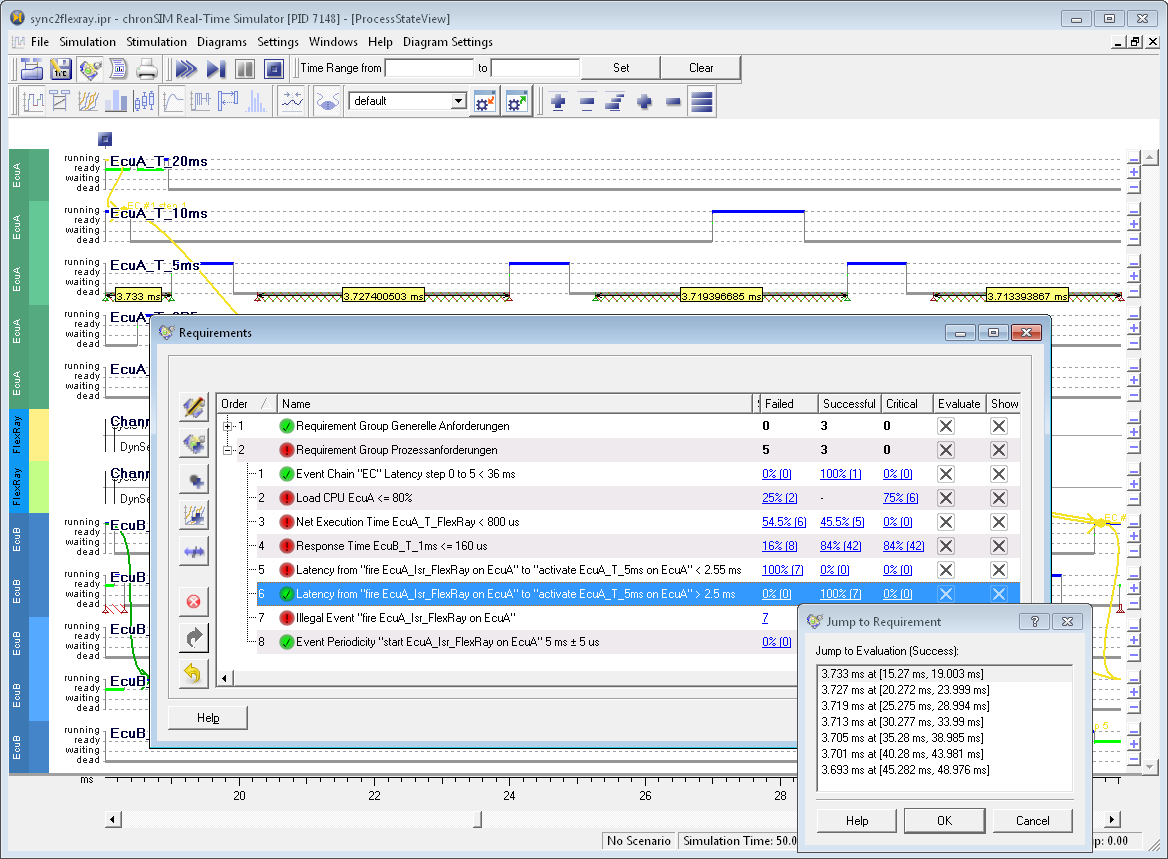

- 7.13 Jump to Requirement

- 7.14 View Profile Controls

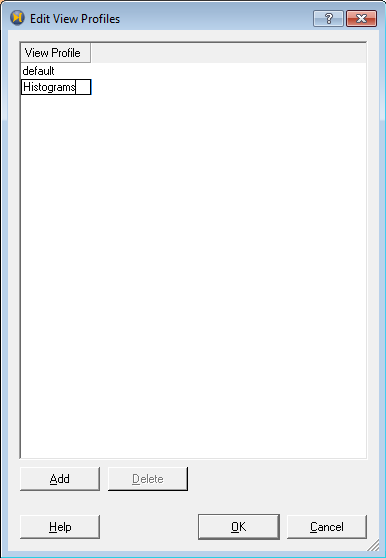

- 7.15 View Profile Dialog

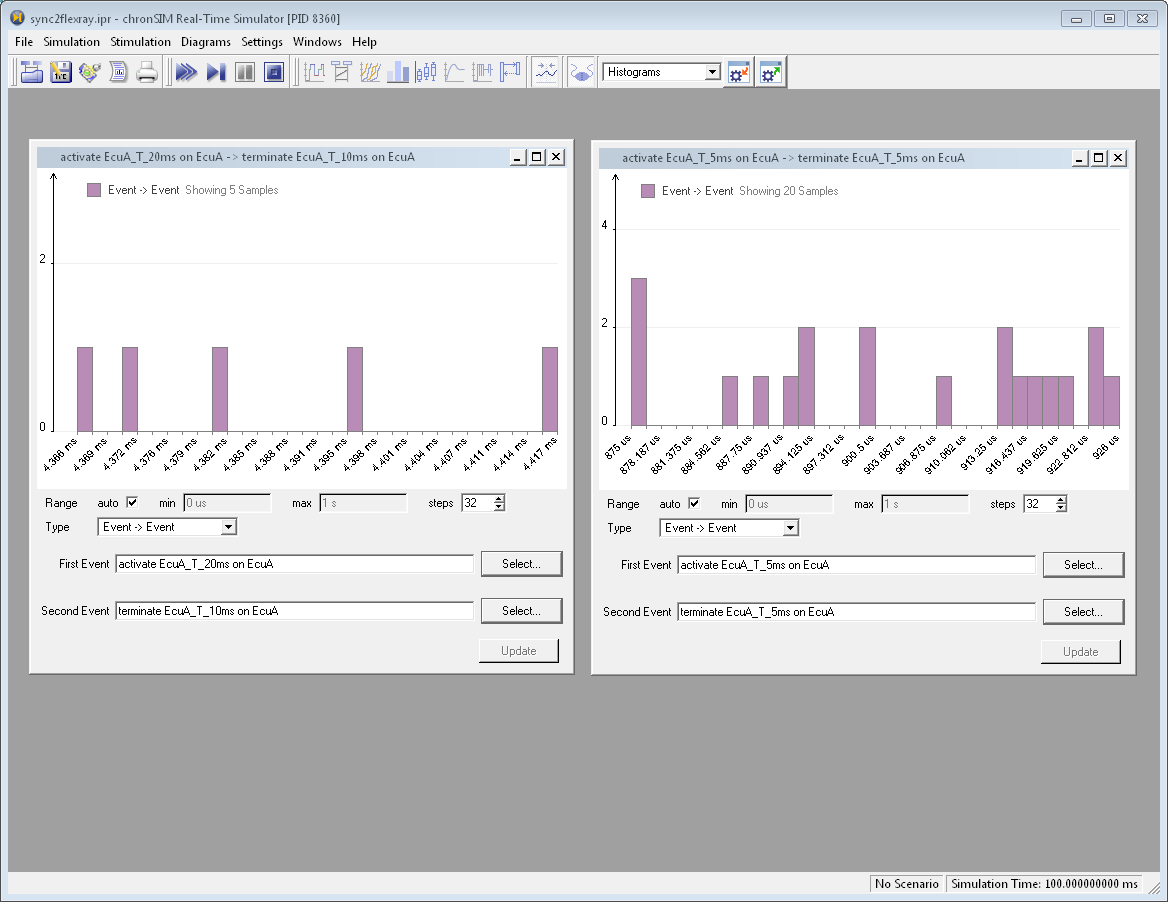

- 7.16 View Profile with two Histograms

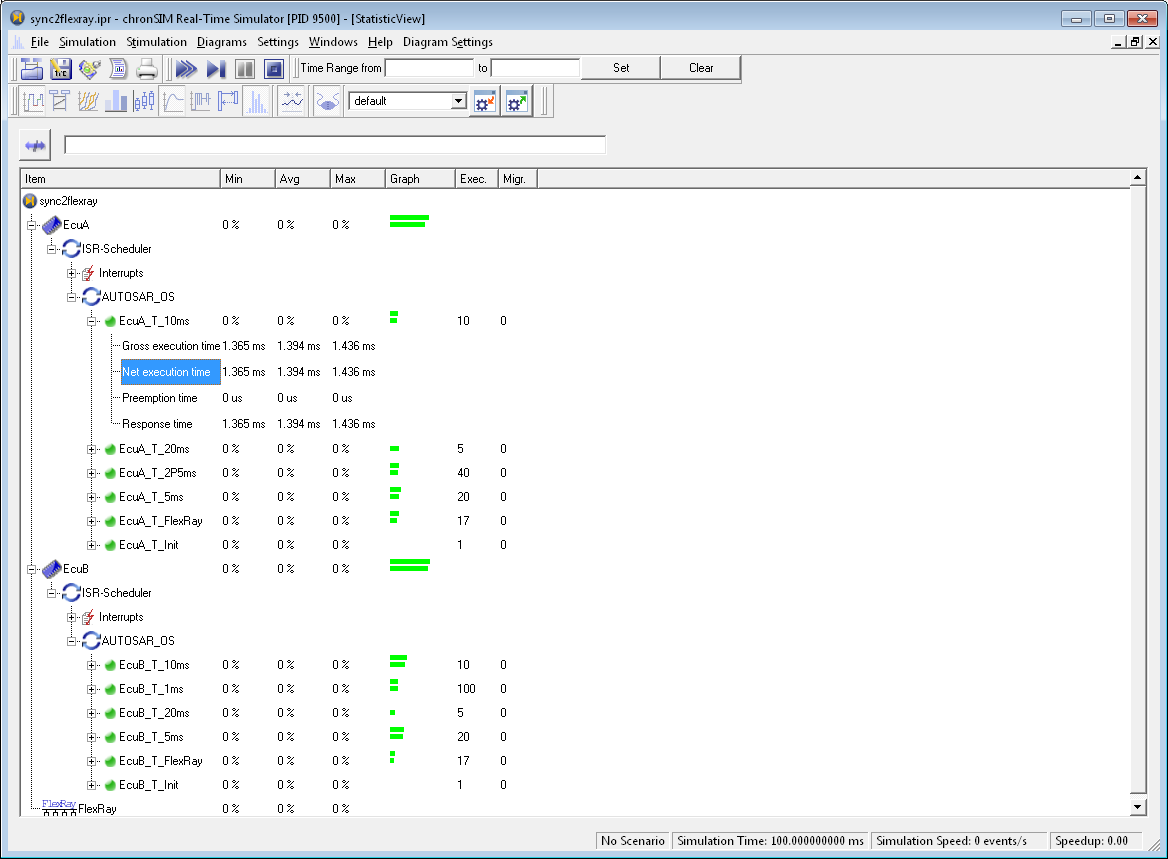

- 7.17 Statistics View

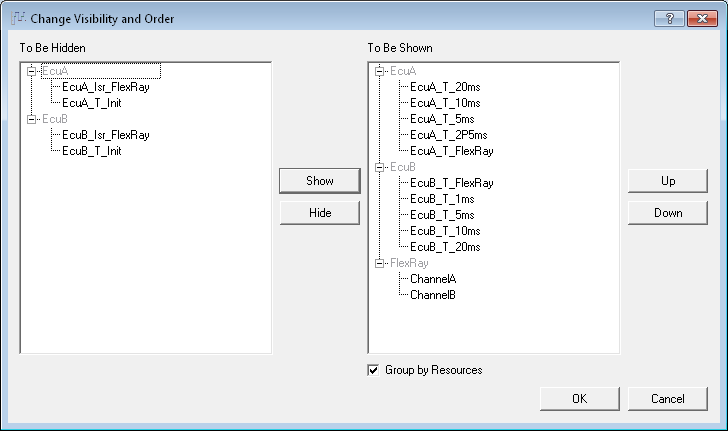

- 7.18 Diagram Order Dialog

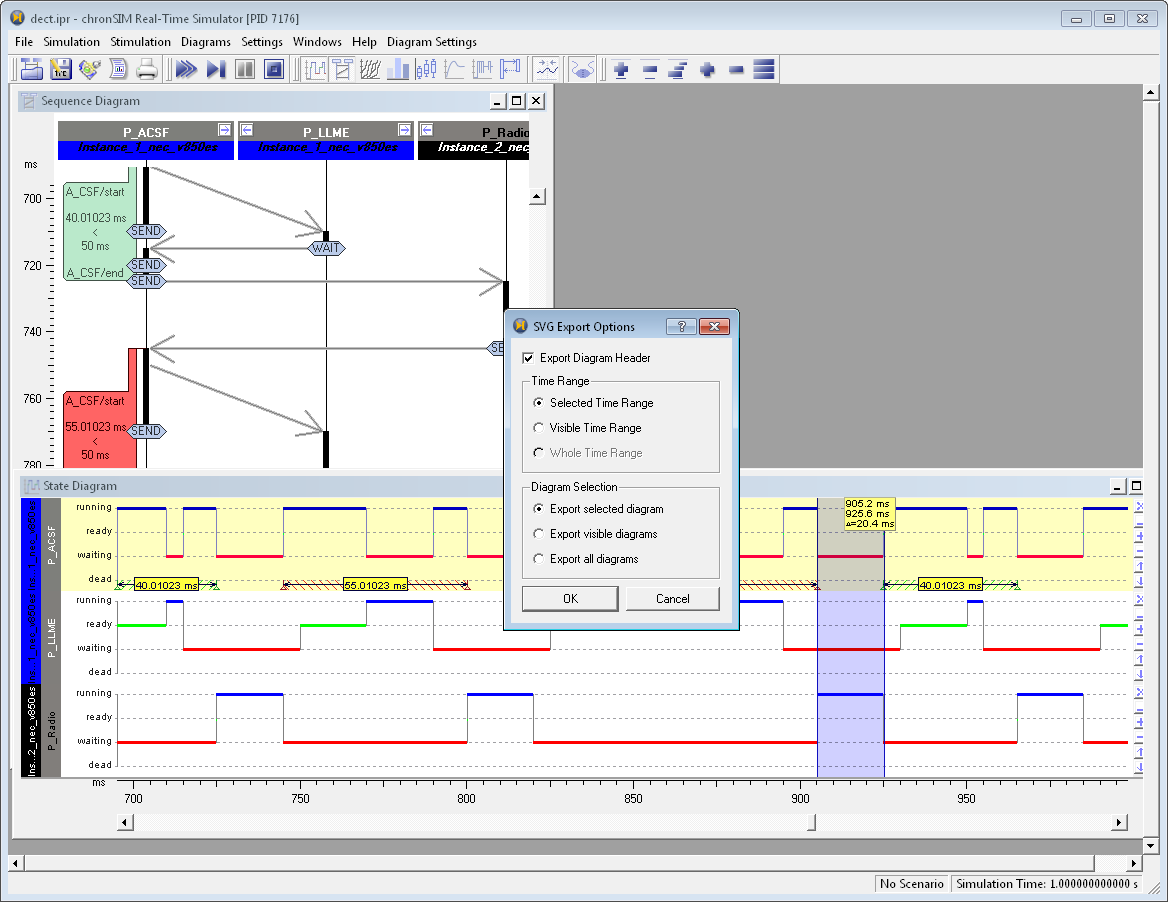

- 7.19 Options for Diagram Export

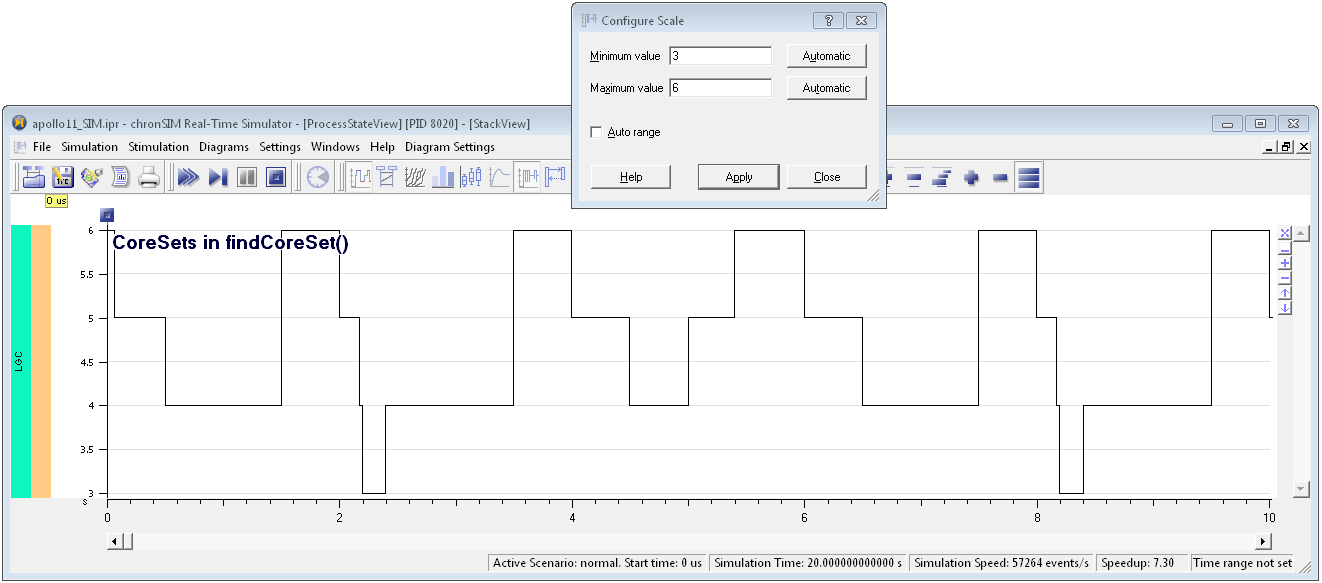

- 7.20 Manual y-Axis Range in Event Diagram

- 7.21 Zoom - Region of Interest

- 7.22 Reference Cursors

- 7.23 chronSIM Real-Time Simulator and Simulation Control Windows

- 7.24 Status-Bar of Real-Time Simulator Window

- 7.25 State Diagram of Example

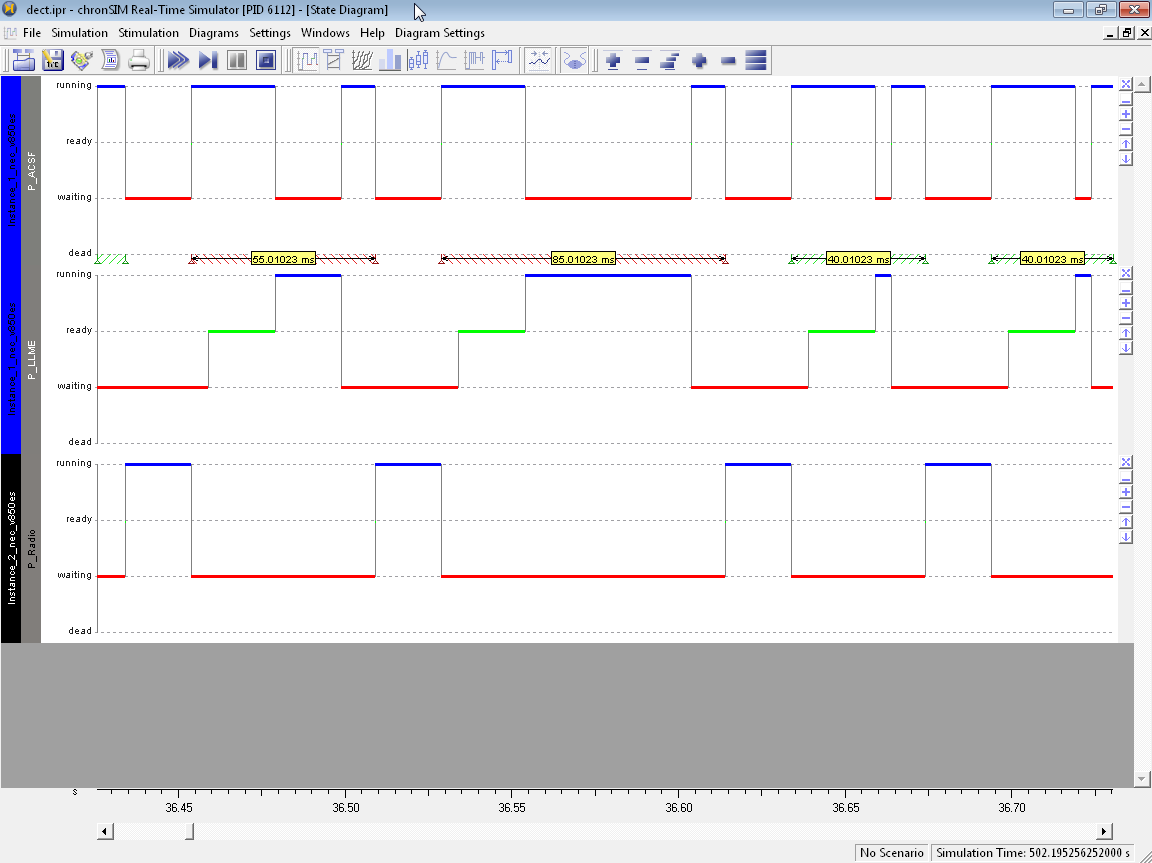

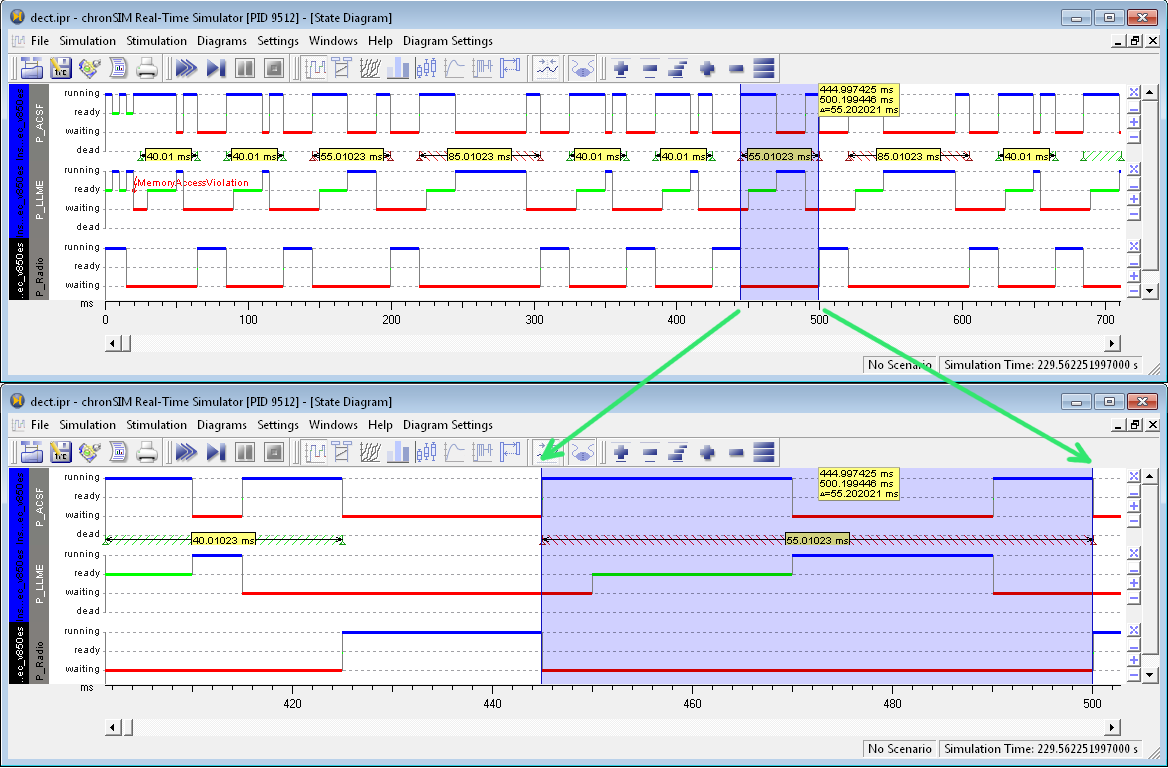

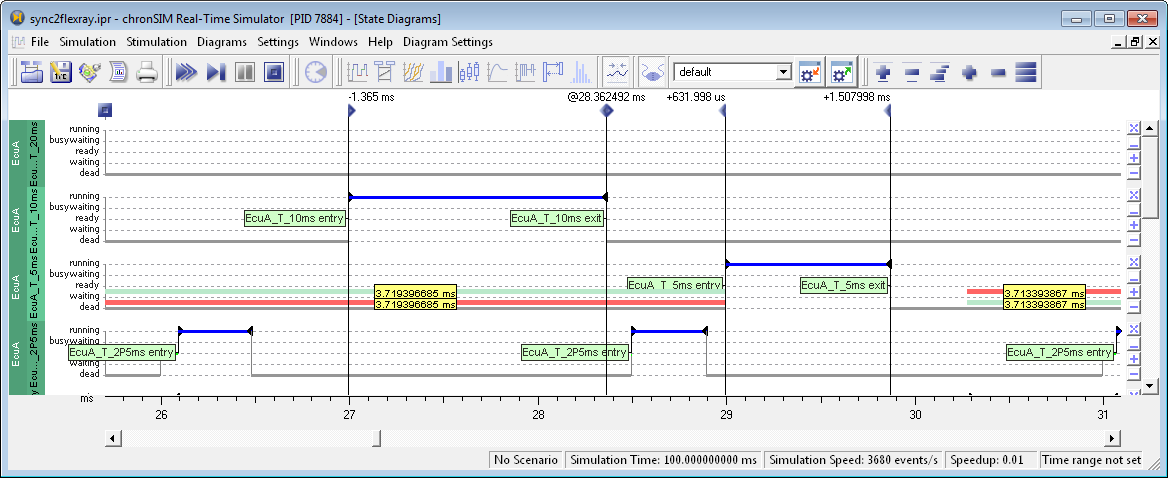

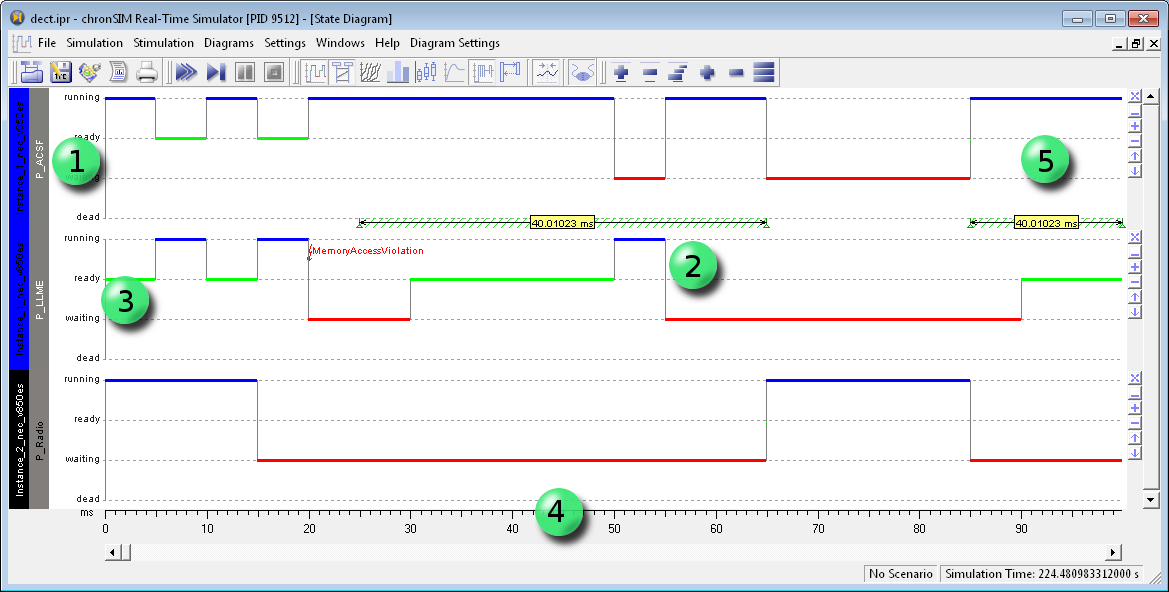

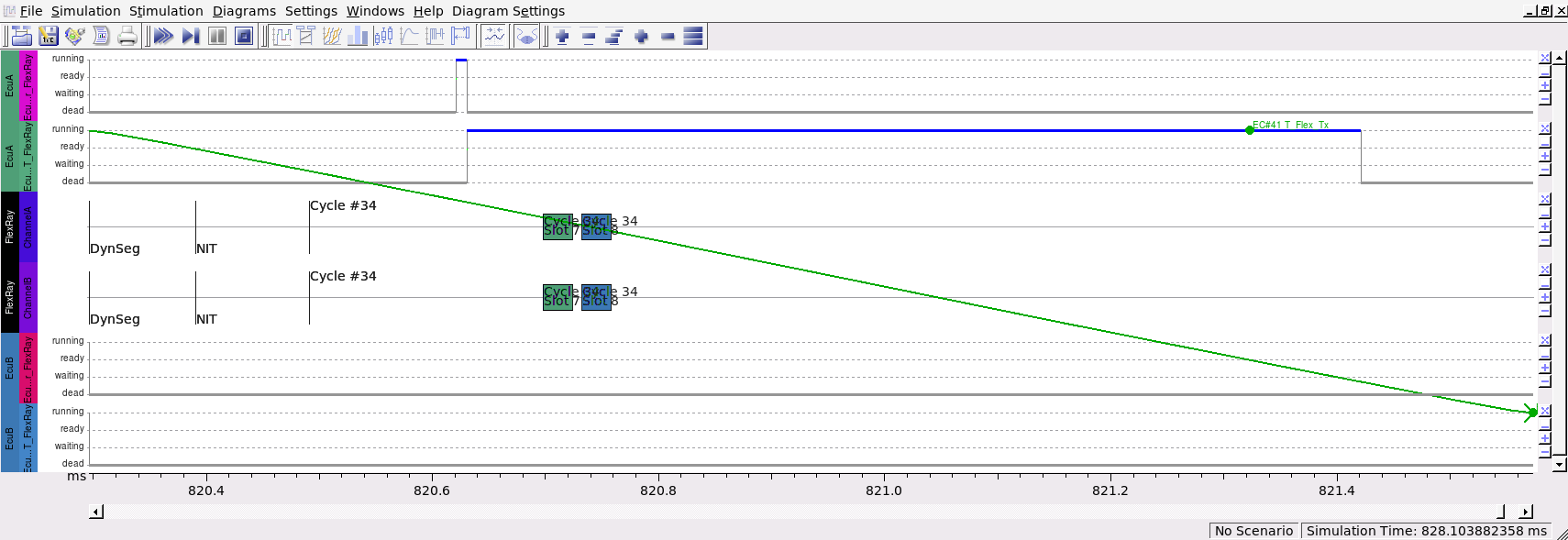

dect.ipr - 7.26 State Diagram showing packets on a FlexRay bus.

- 7.27 Event Chain Visibility Dialog

- 7.28 State Diagram with Memory Access Violation

- 7.29 State Diagram of Example

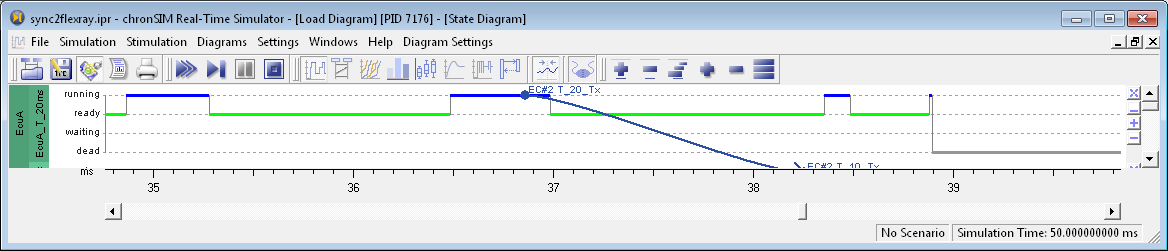

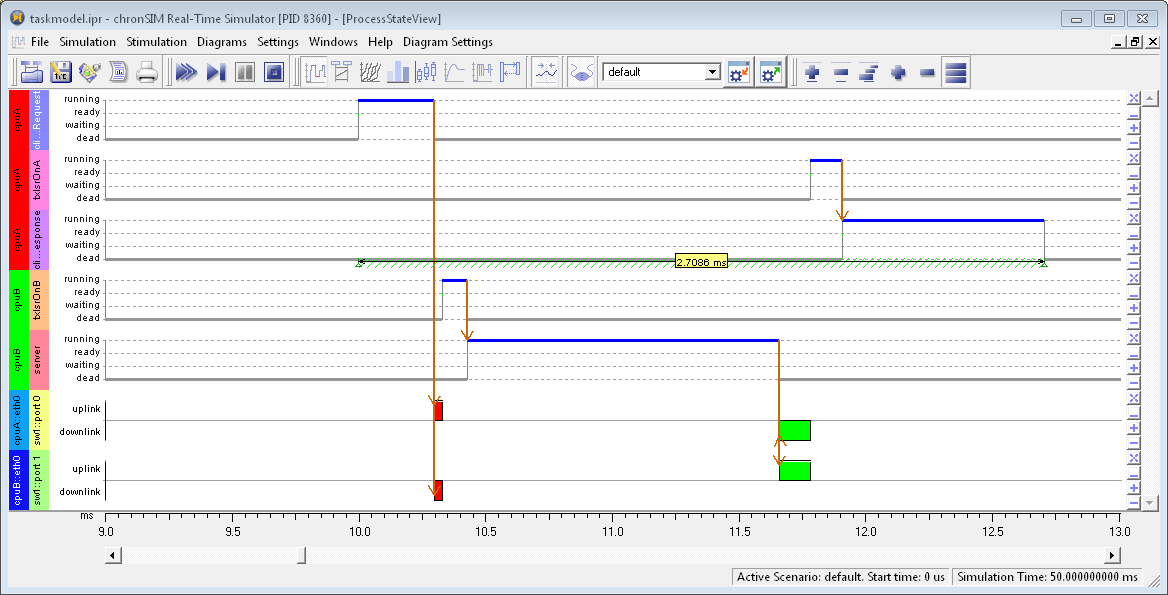

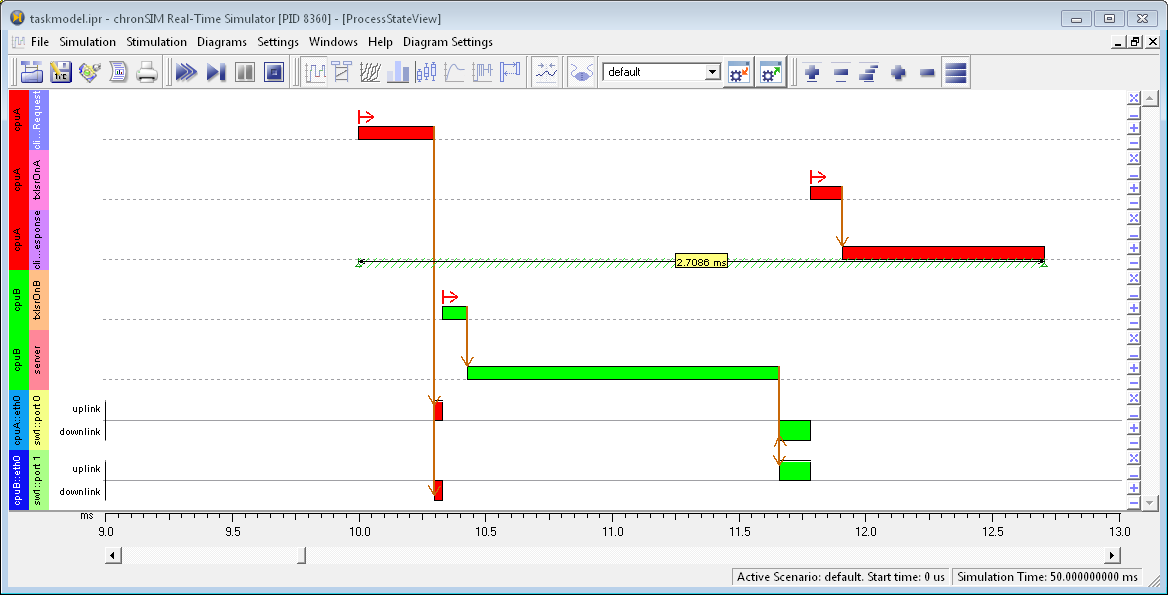

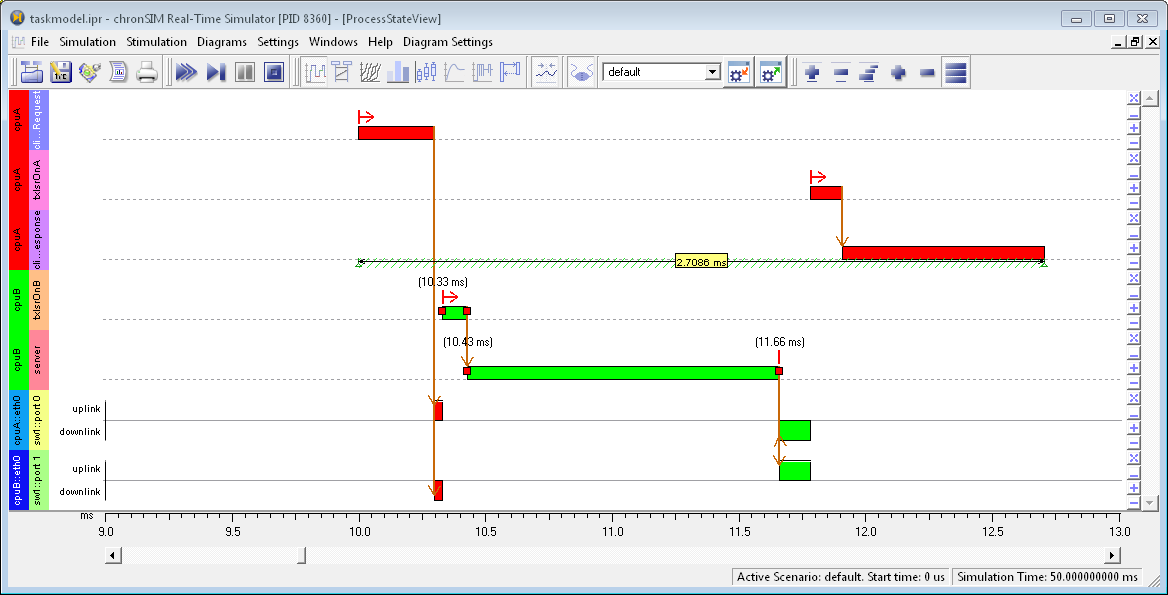

ethernet/taskmodel.ipr - 7.30 Gantt Diagram of Example

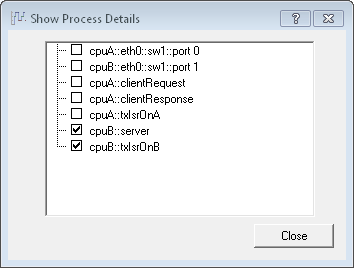

ethernet/taskmodel.ipr - 7.31 Show Process Details Dialog

- 7.32 Gantt Diagram with Process Details

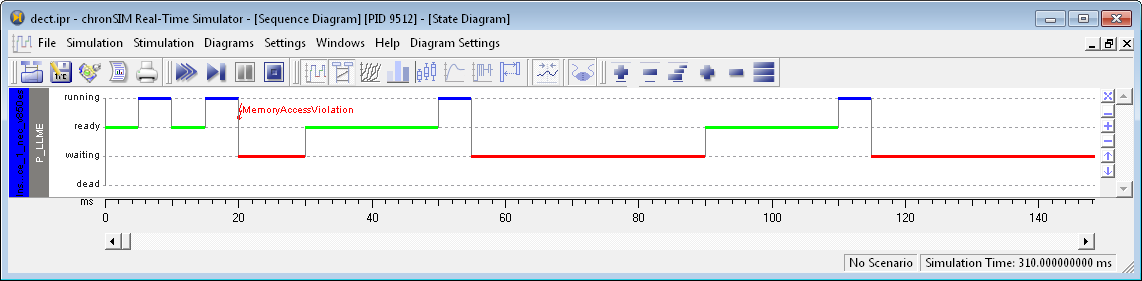

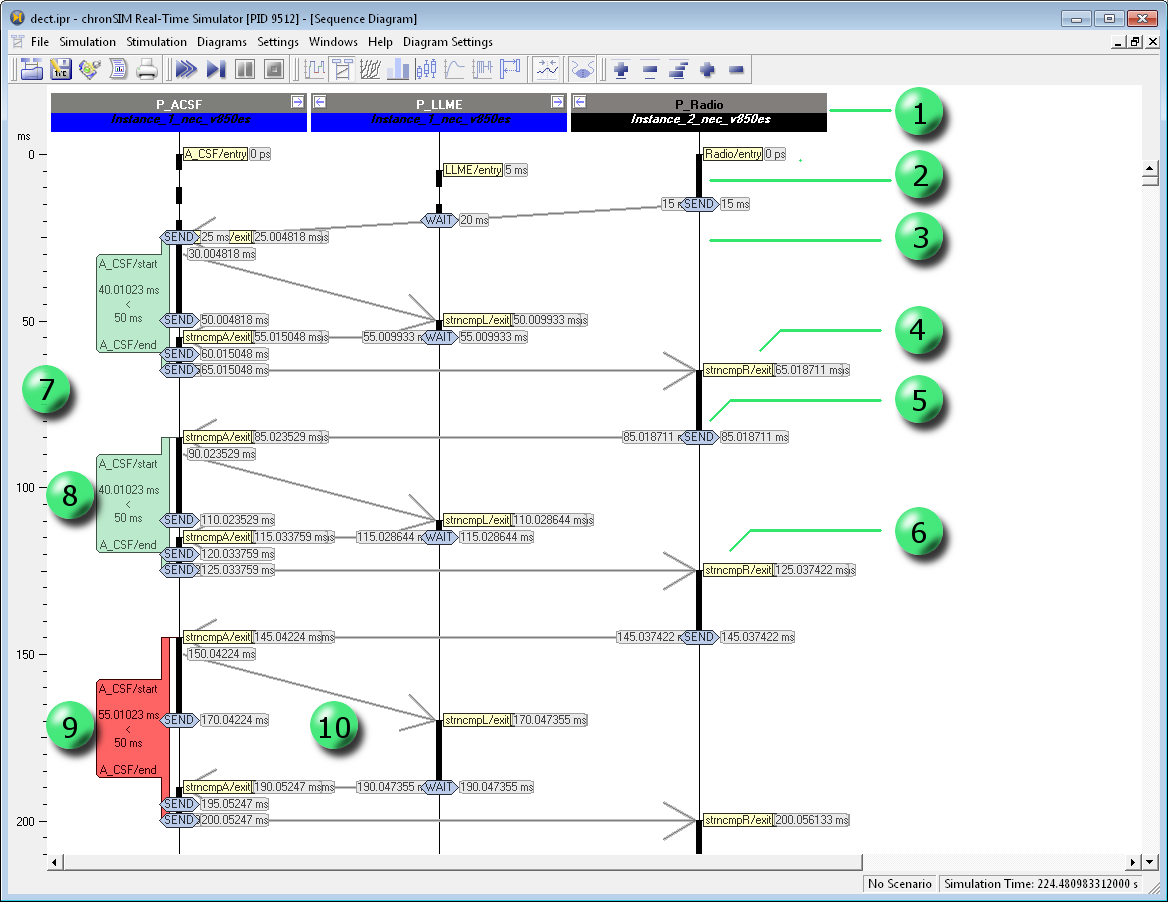

- 7.33 Sequence Diagram of Example

dect.ipr - 7.34 Sequence Diagram

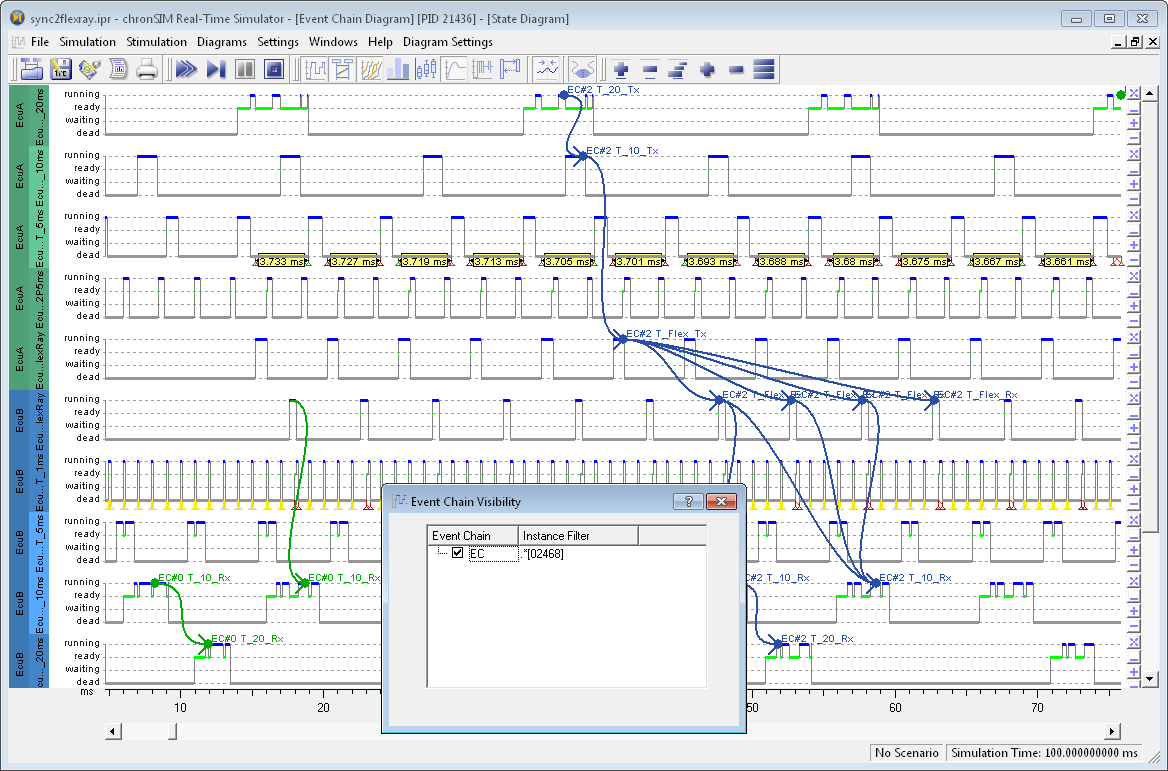

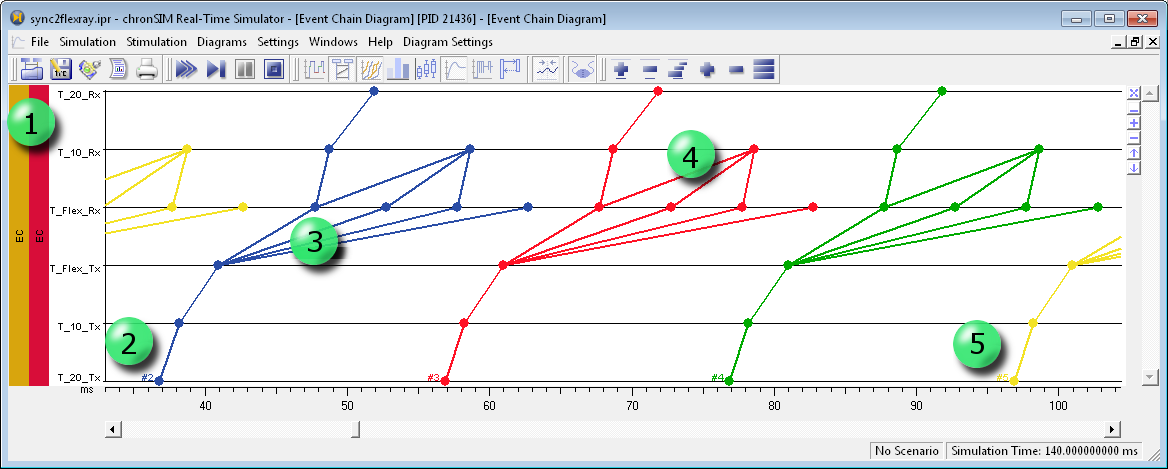

- 7.35 Event Chain Diagram

- 7.36 Event Chain Visibility Dialog

- 7.37 Histogram of Interrupt Jitter

- 7.38 Box Plot Diagram of Process Response Times

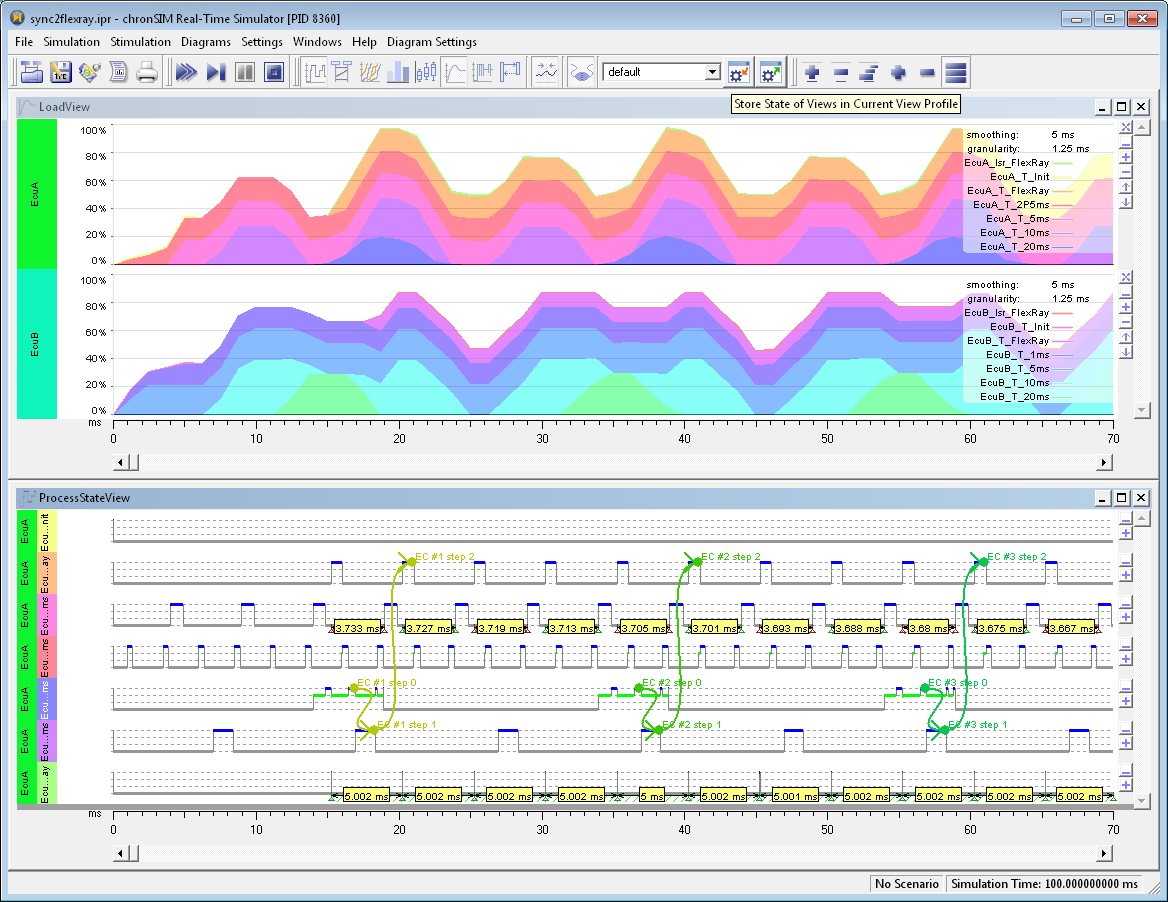

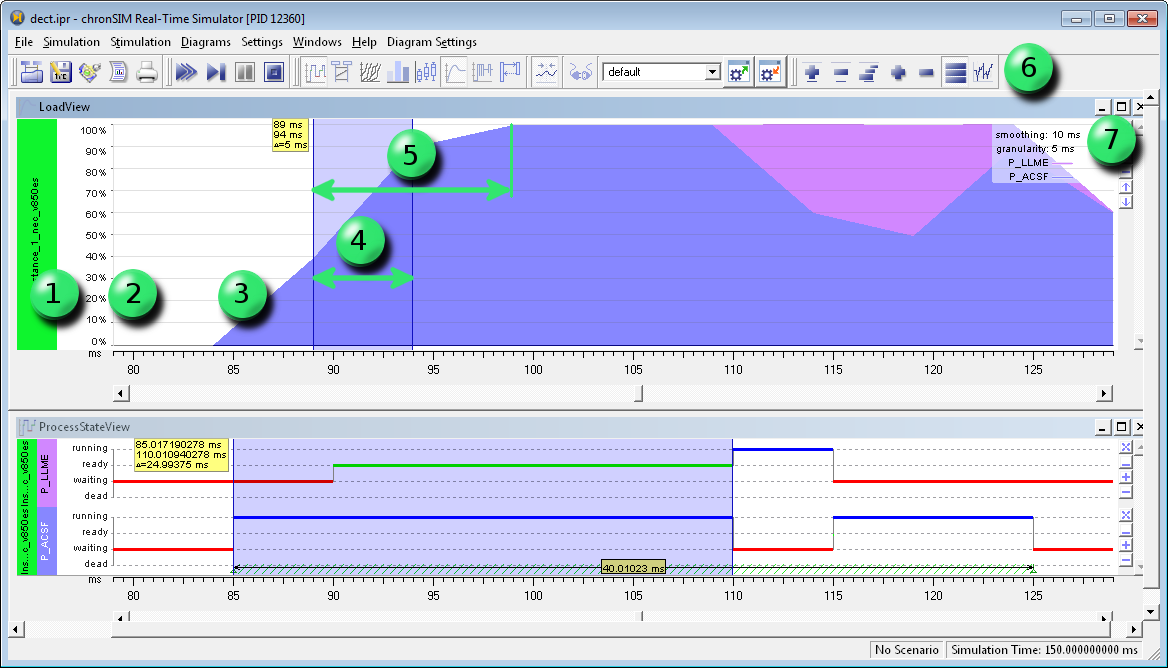

- 7.39 Load Diagram of a CPU with two tasks

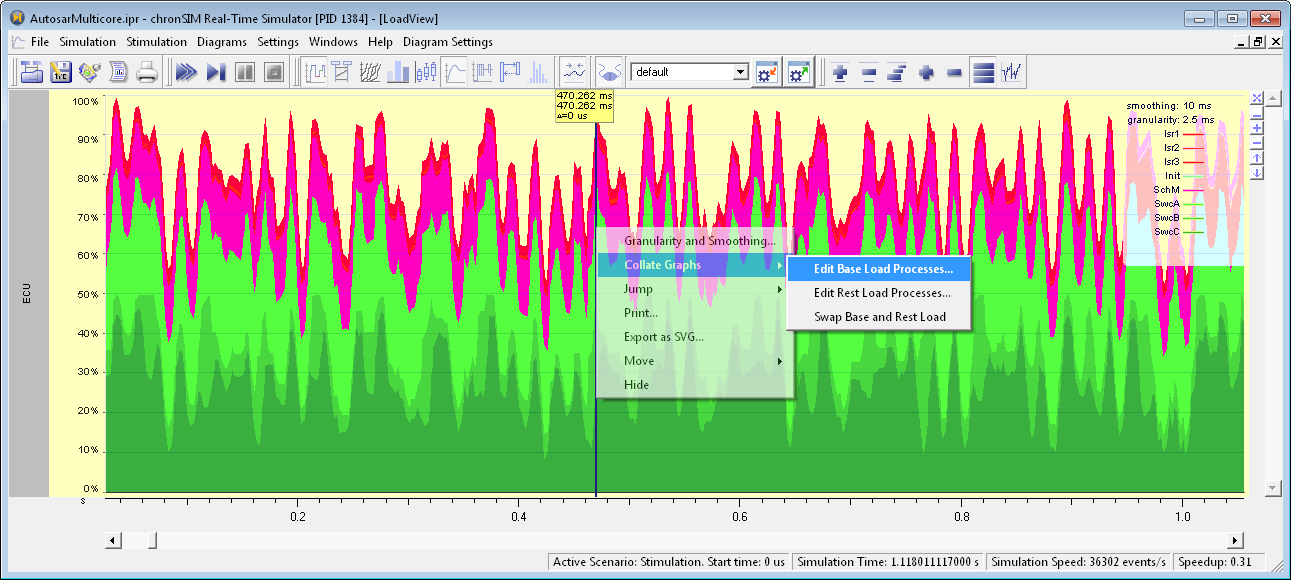

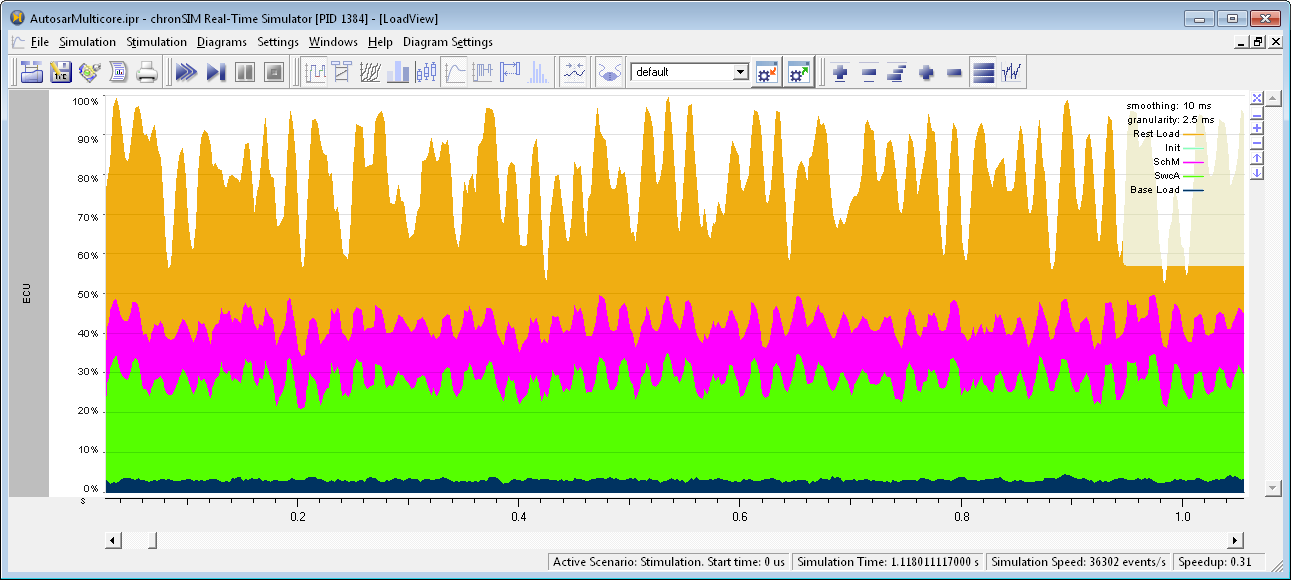

- 7.40 Collating Load Graphs

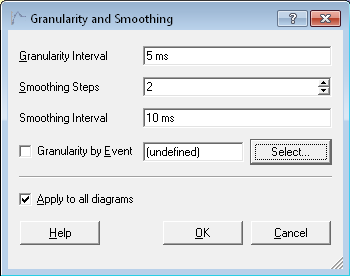

- 7.41 Granularity and Smoothing Dialog

- 7.42 Stack Diagram of example

dect.ipr - 7.43 Select an event item

- 7.44 Adding and Removing an Event Diagram

- 7.45 Nesting Diagram of Example

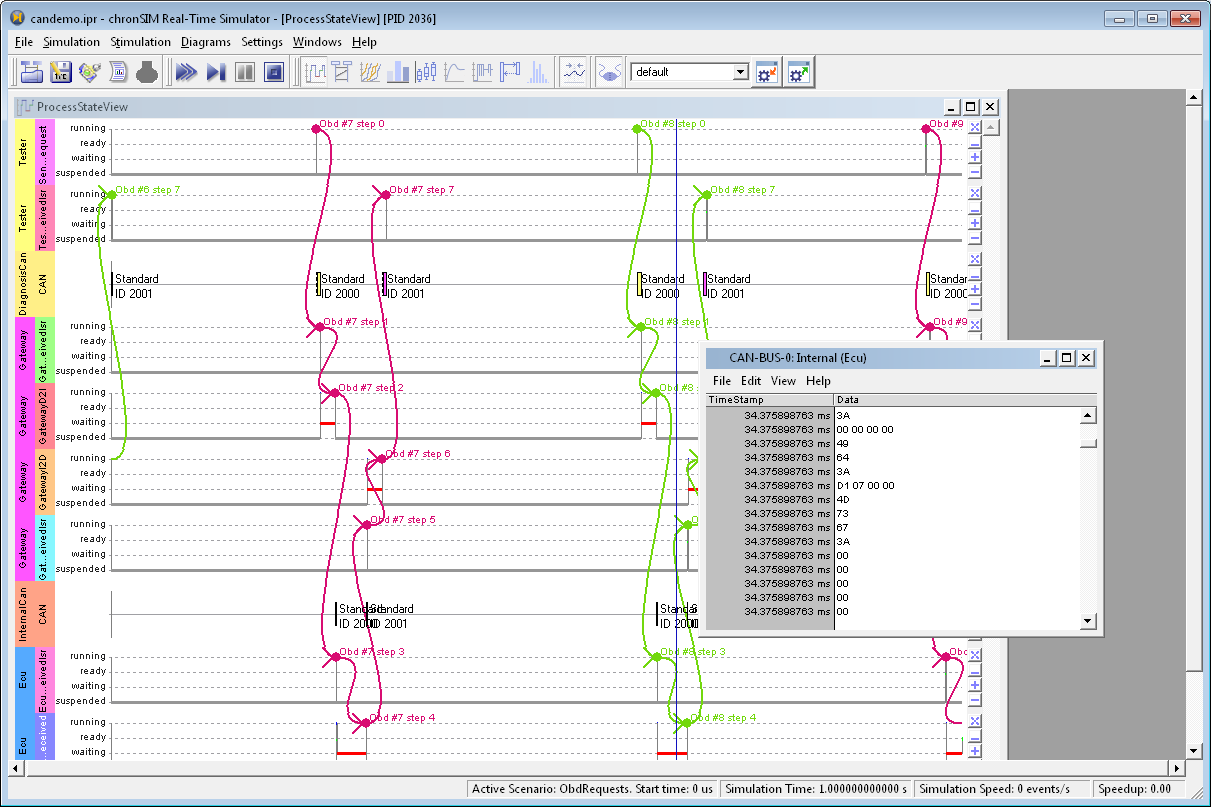

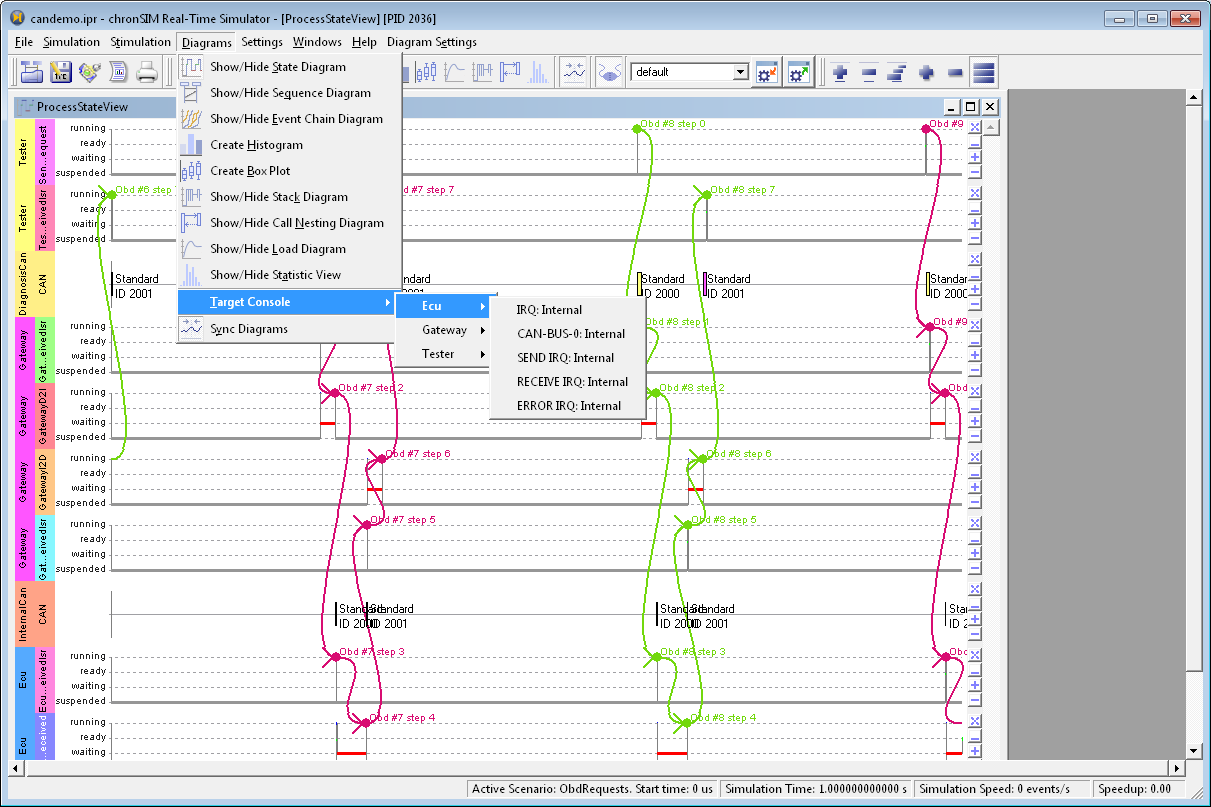

dect.ipr - 7.46 ConsoleView Example

Can/candemo.ipr - 7.47 ConsoleView Example

Can/candemo.ipr - 7.48 Scenario from CSV

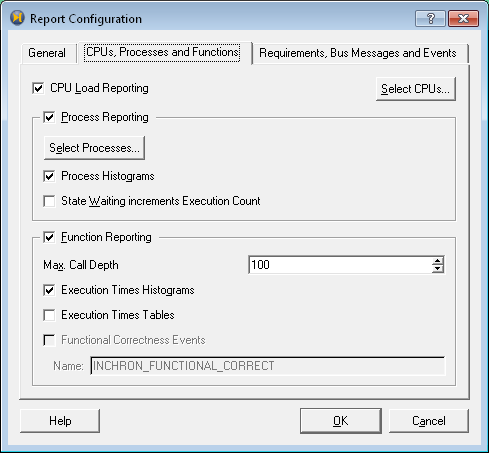

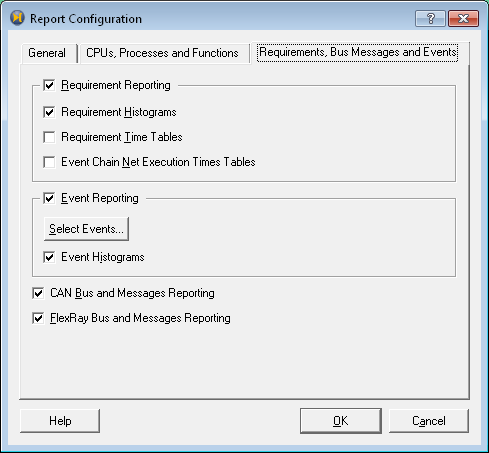

- 7.49 Report Configuration Dialog - General Options

- 7.50 Report Configuration Dialog - CPU and Process Options

- 7.51 Report Configuration Dialog - Bus, Event and Requirement Options

- 8.1 INCHRON Tool-Suite Window With chronVAL Task Interference Example

- 8.2 System Module Window With chronVAL Task Interference Example

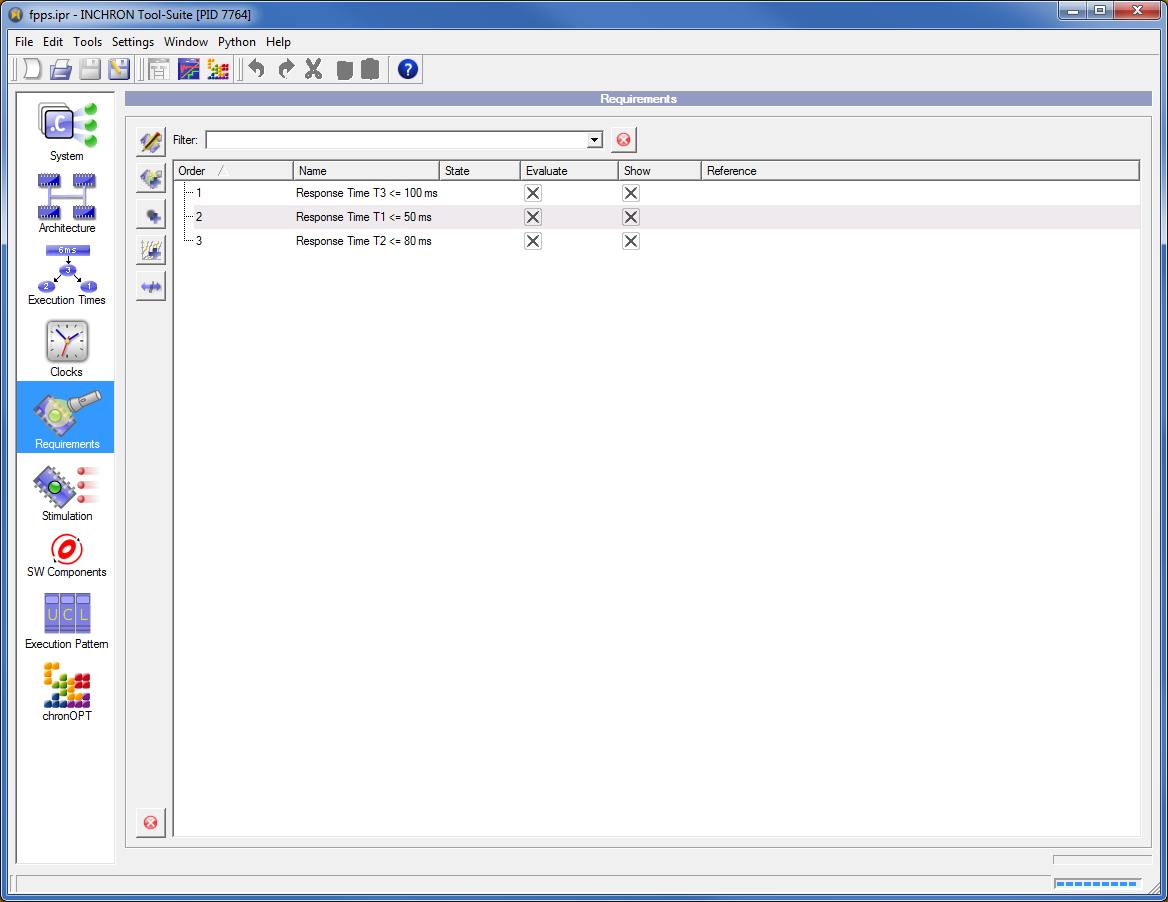

- 8.3 Requirements Module Window With chronVAL Task Interference Example

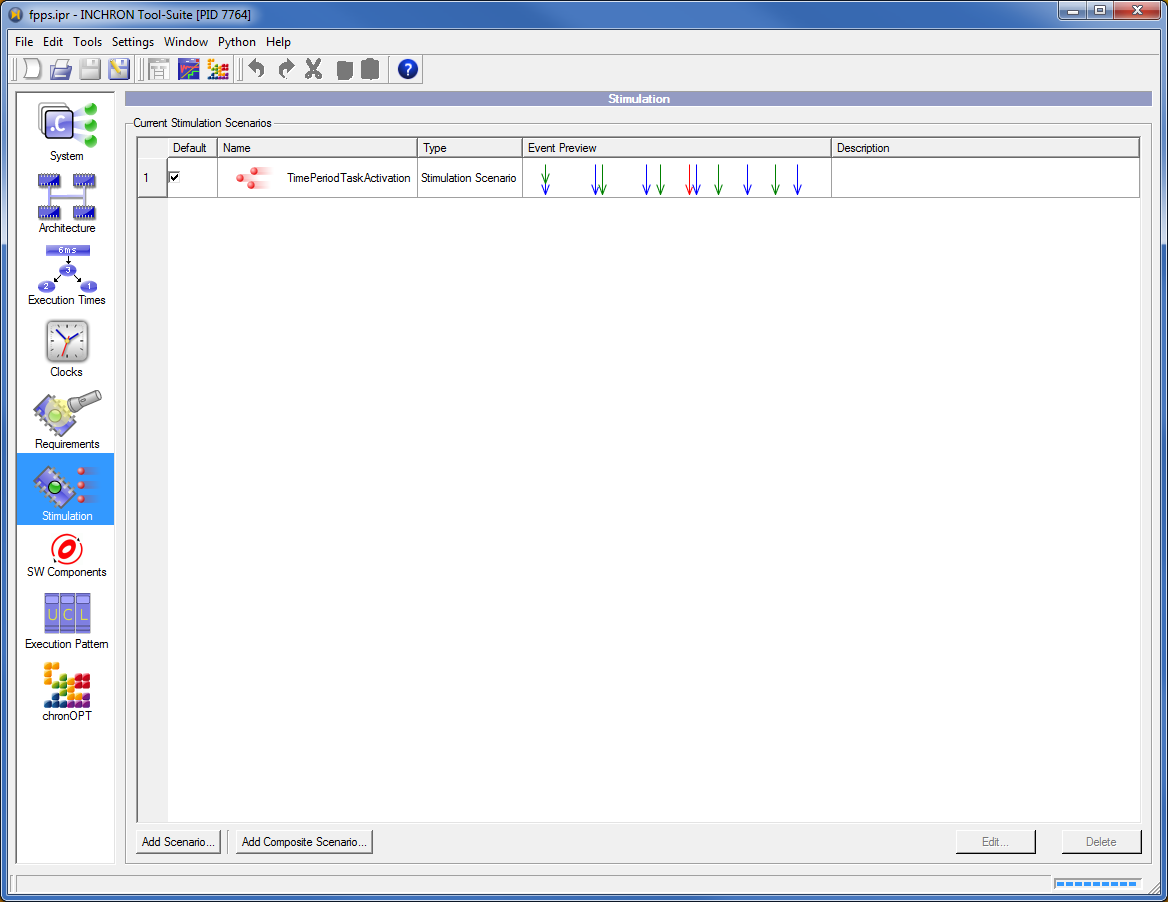

- 8.4 Stimulation Module Window With chronVAL Task Interference Example

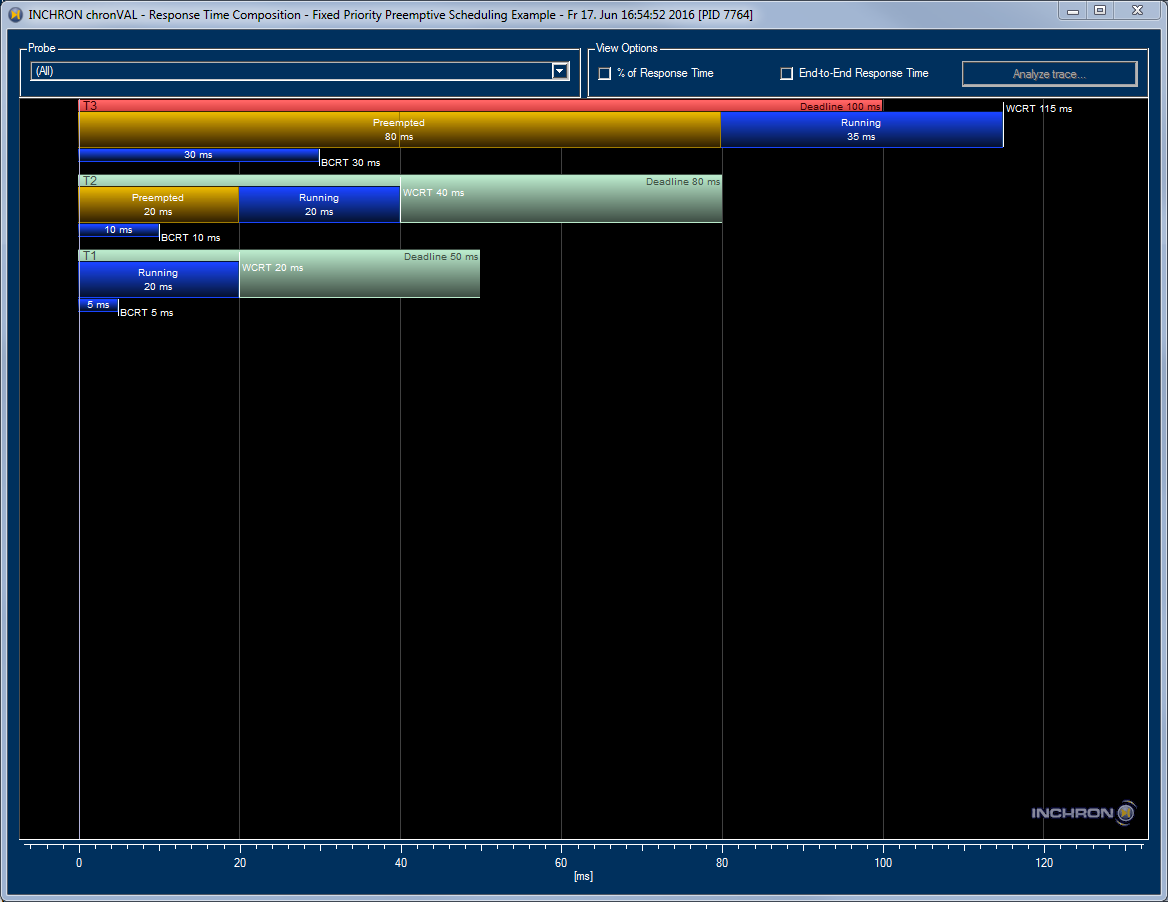

- 8.5 Response Time Composition Window for chronVAL Task Interference Example

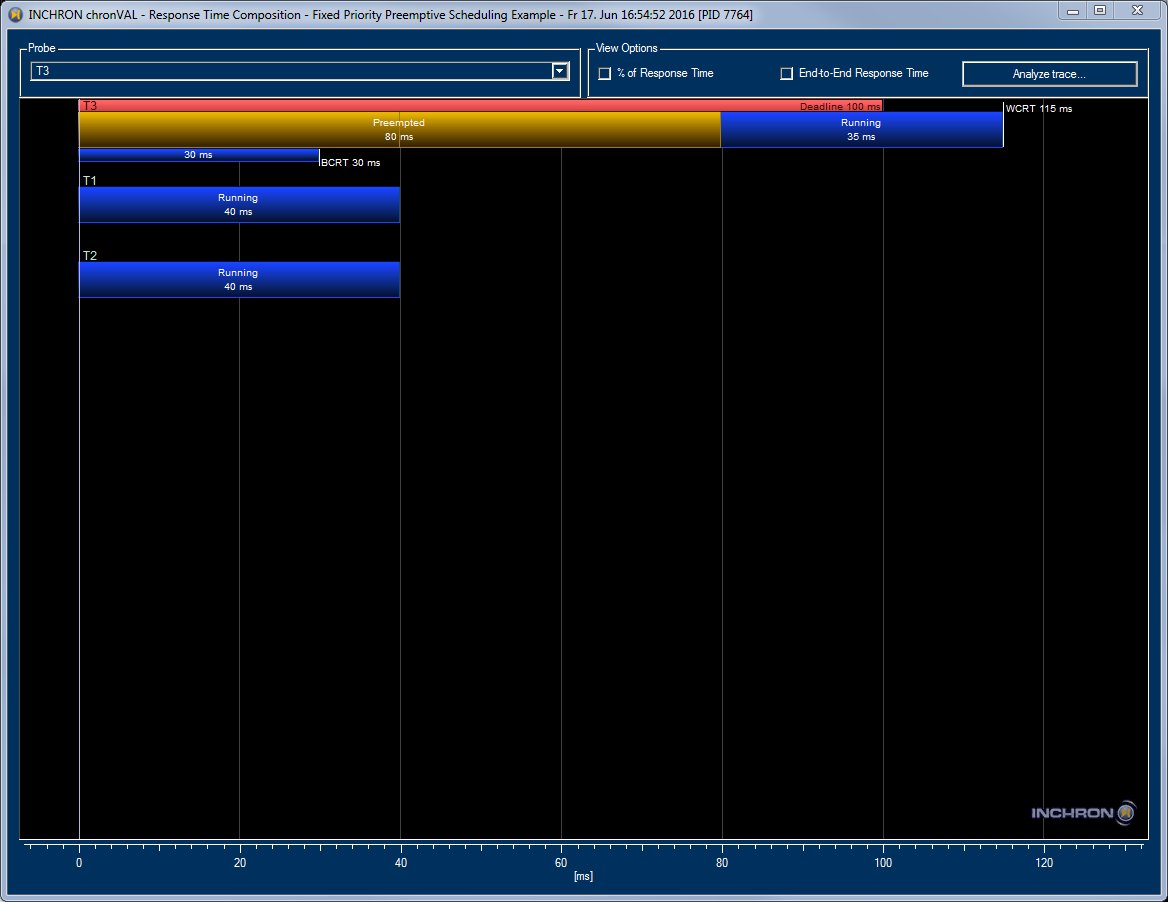

- 8.6 Response Time Composition Window of Task T3

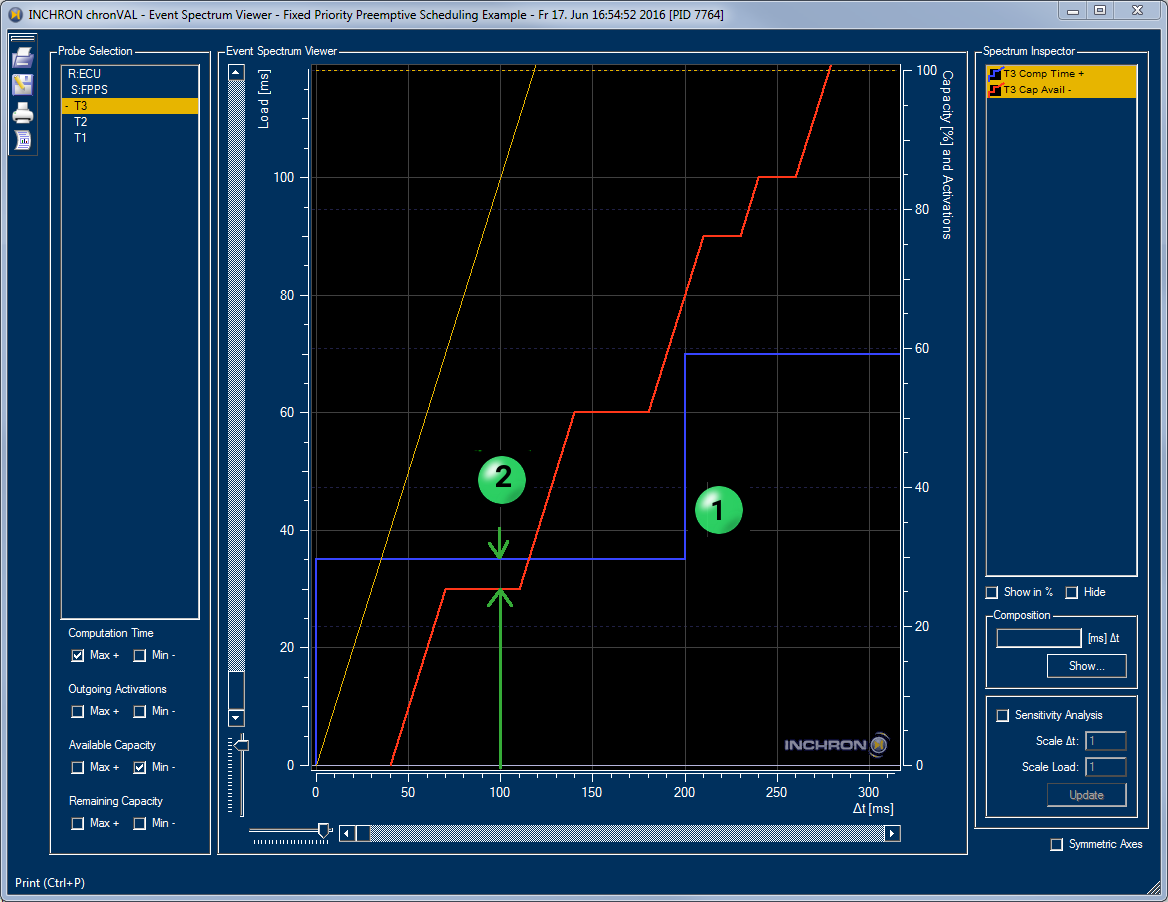

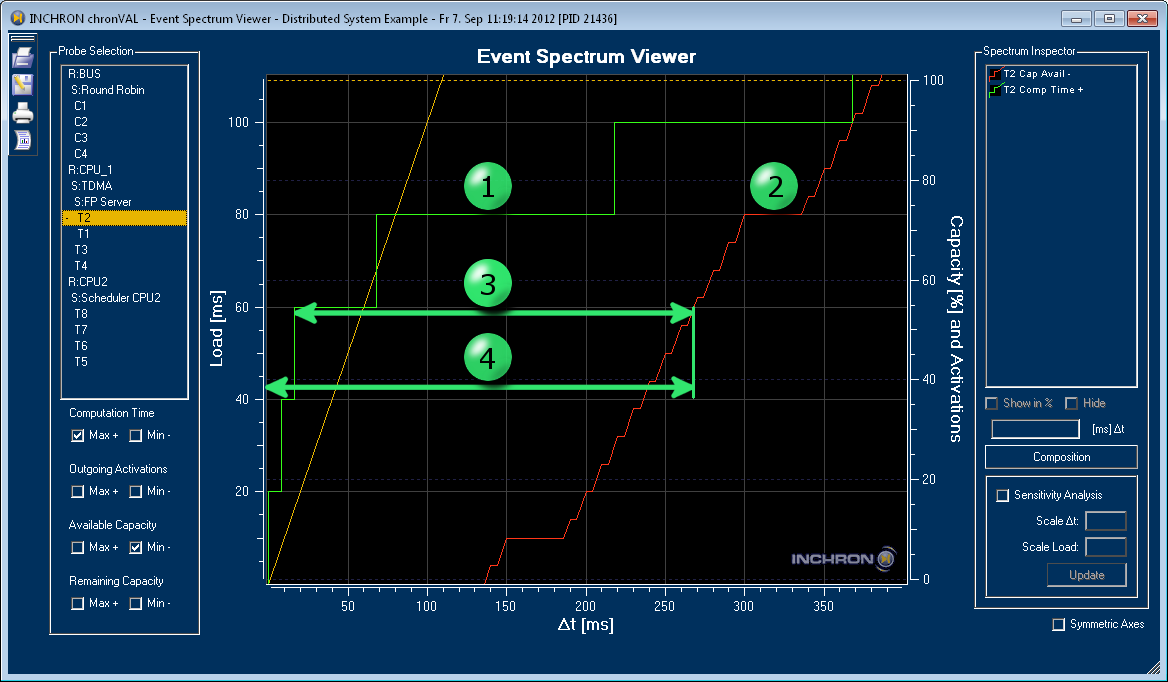

- 8.7 Event Spectrum Diagram for Task T3

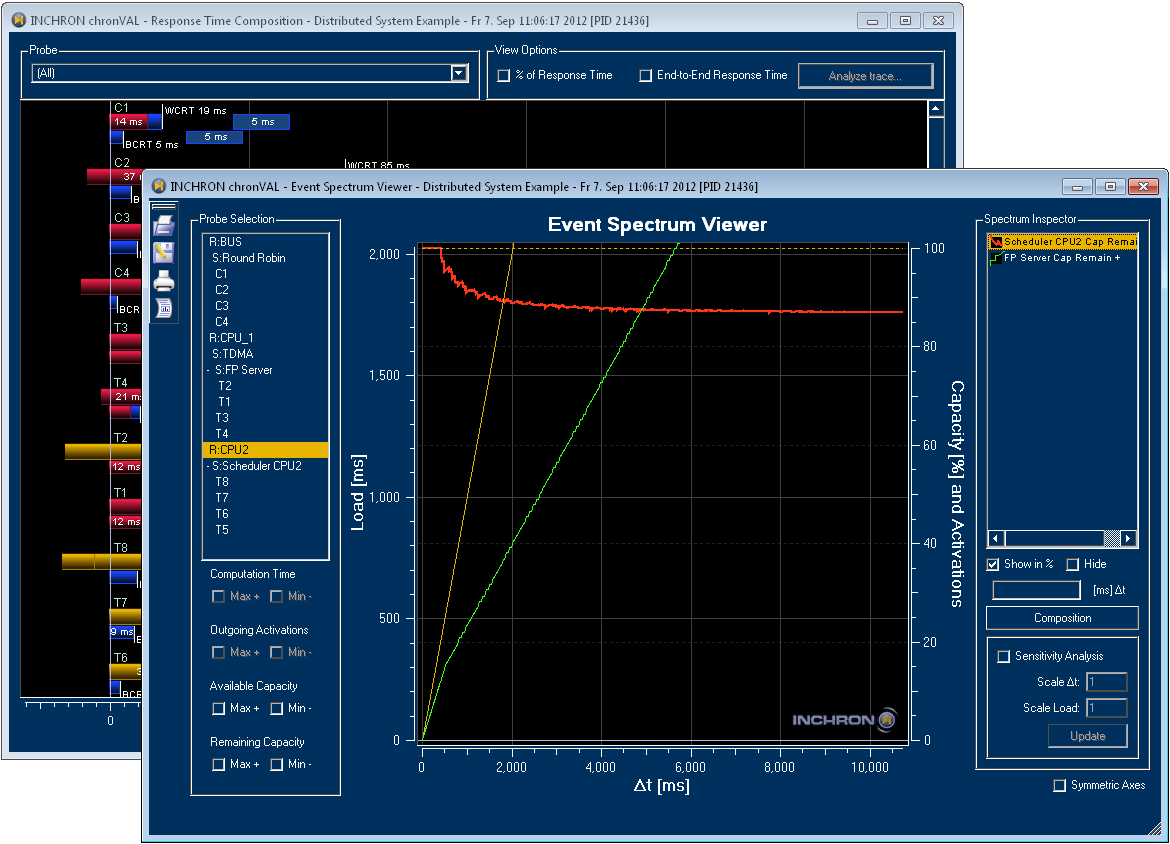

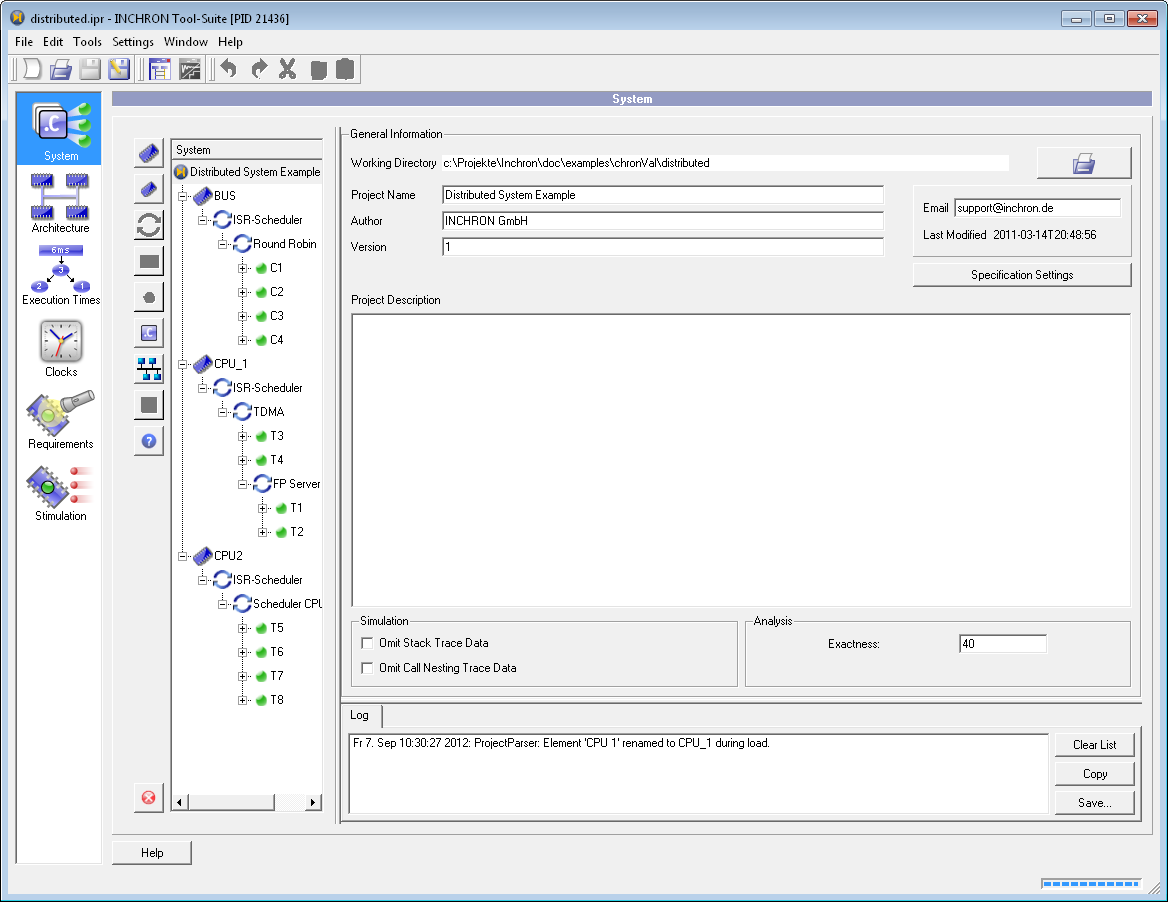

- 8.8 INCHRON Tool-Suite Window With chronVAL Example

- 8.9 chronVAL Analysis Result Windows

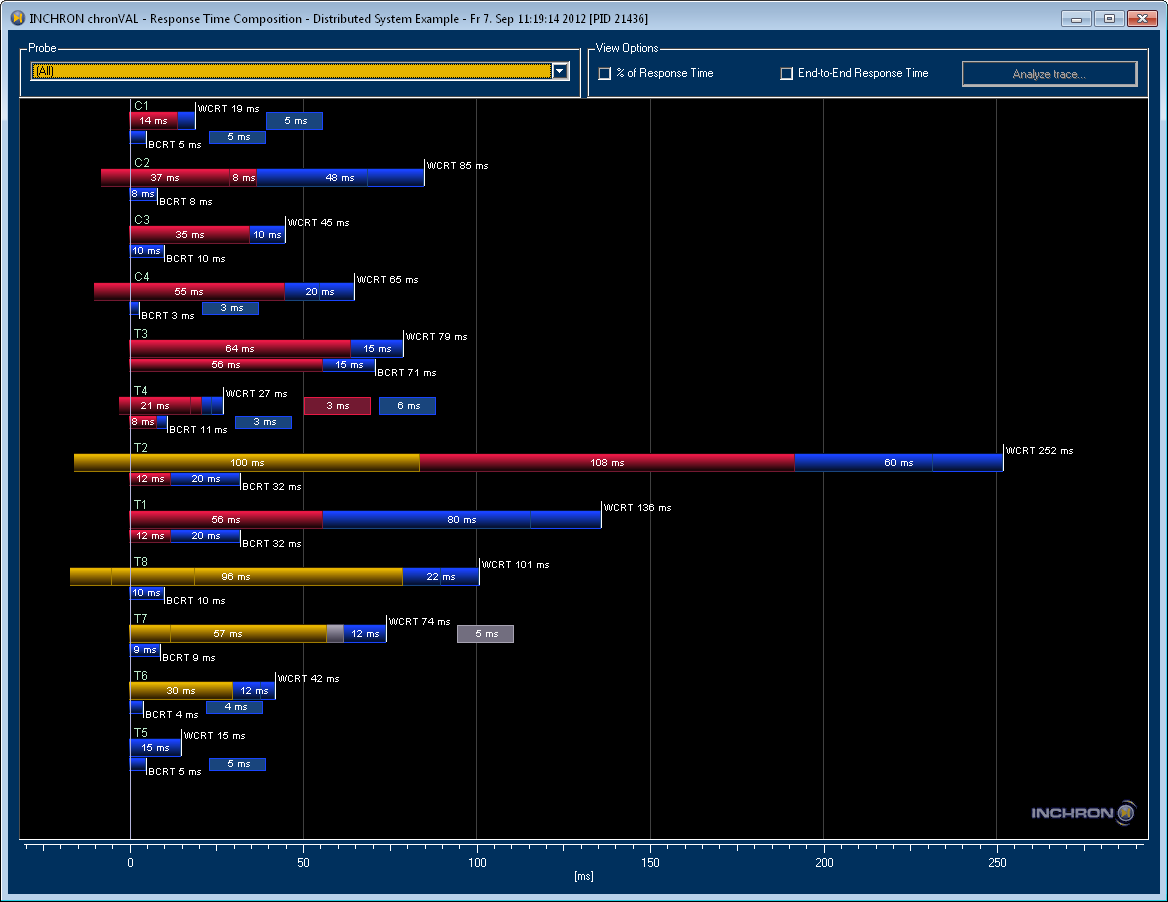

- 8.10 Response Time Overview

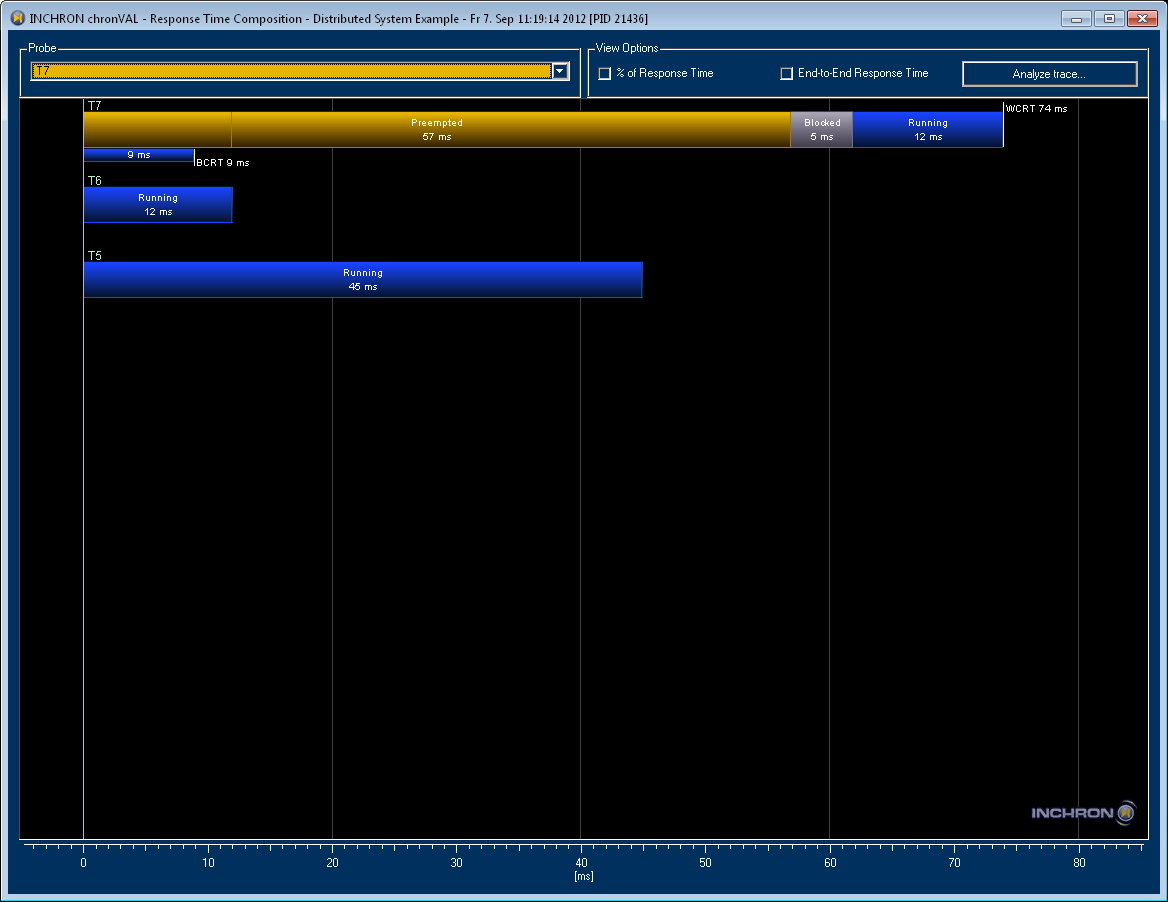

- 8.11 Response Time of Process T7

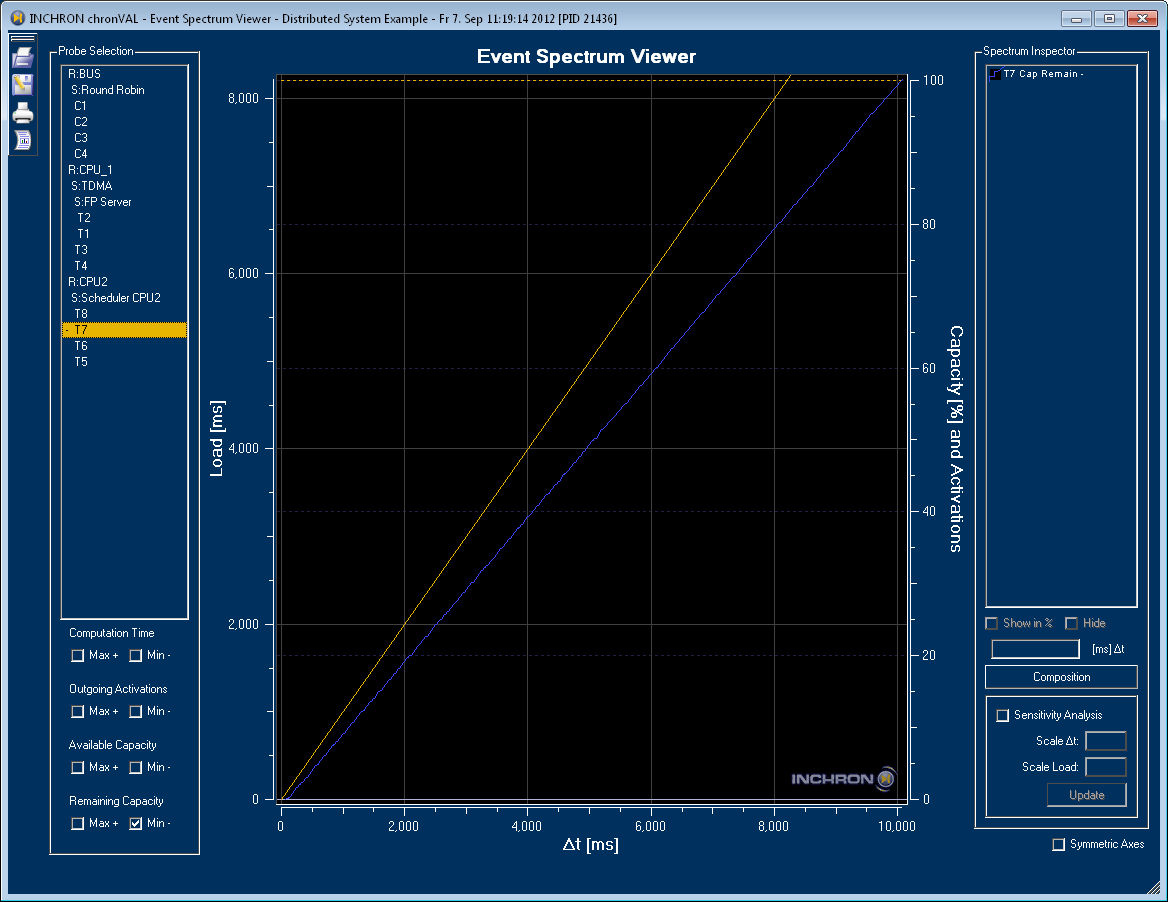

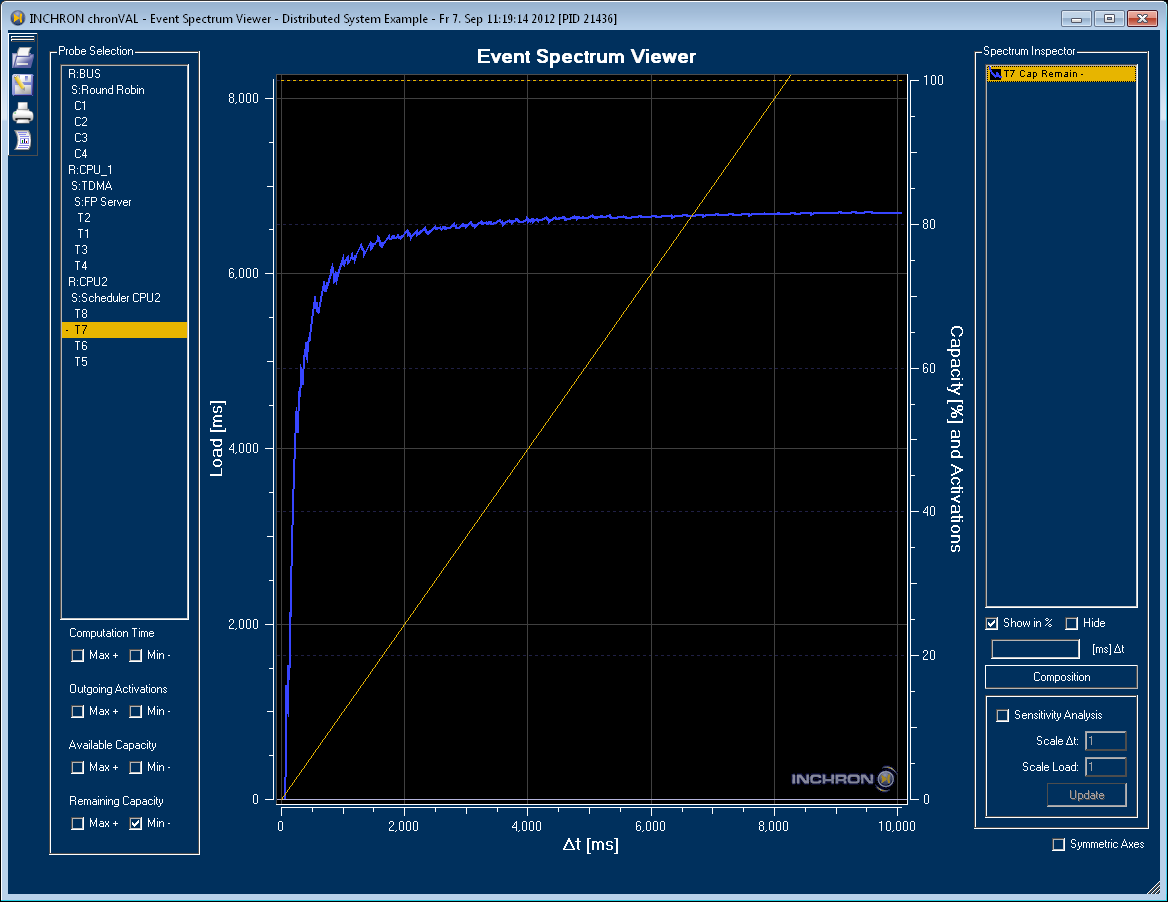

- 8.12 Remaining Capacity as Interval Diagram

- 8.13 Relative Remaining Capacity Diagram

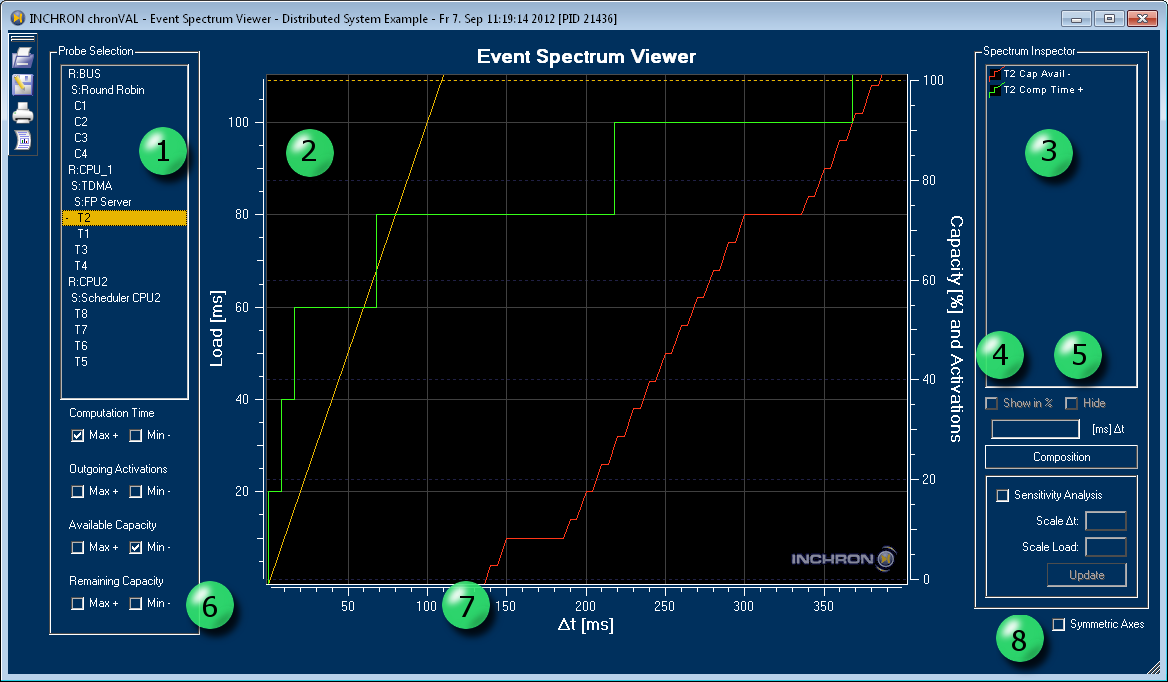

- 8.14 Event Spectrum Visualization

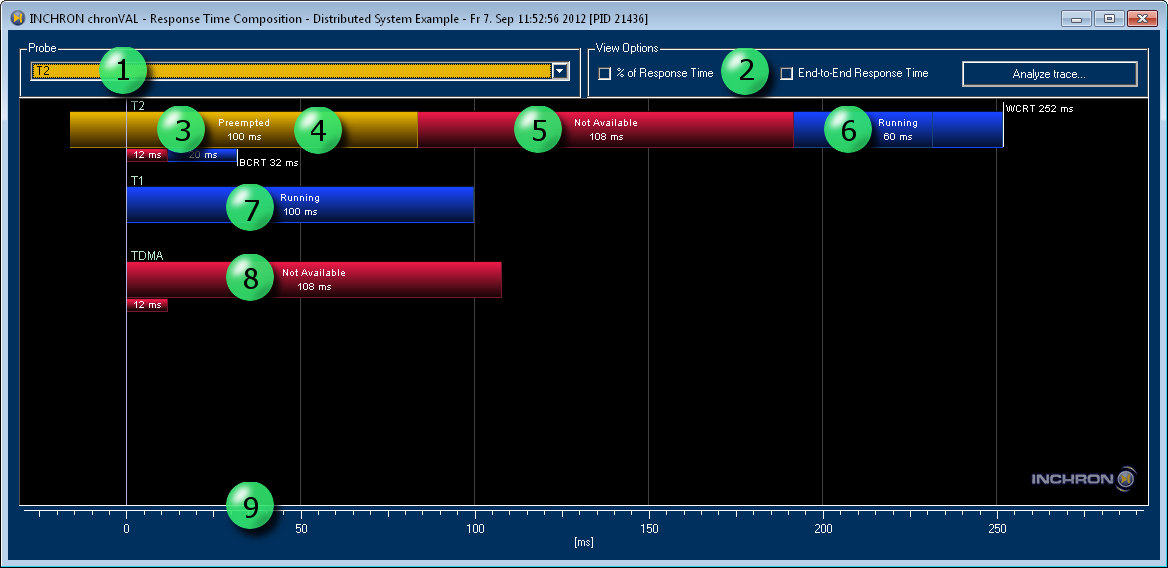

- 8.15 Process T2 Response Time

- 8.16 Illustration of Response Time of Process T2 in the Event Spectrum

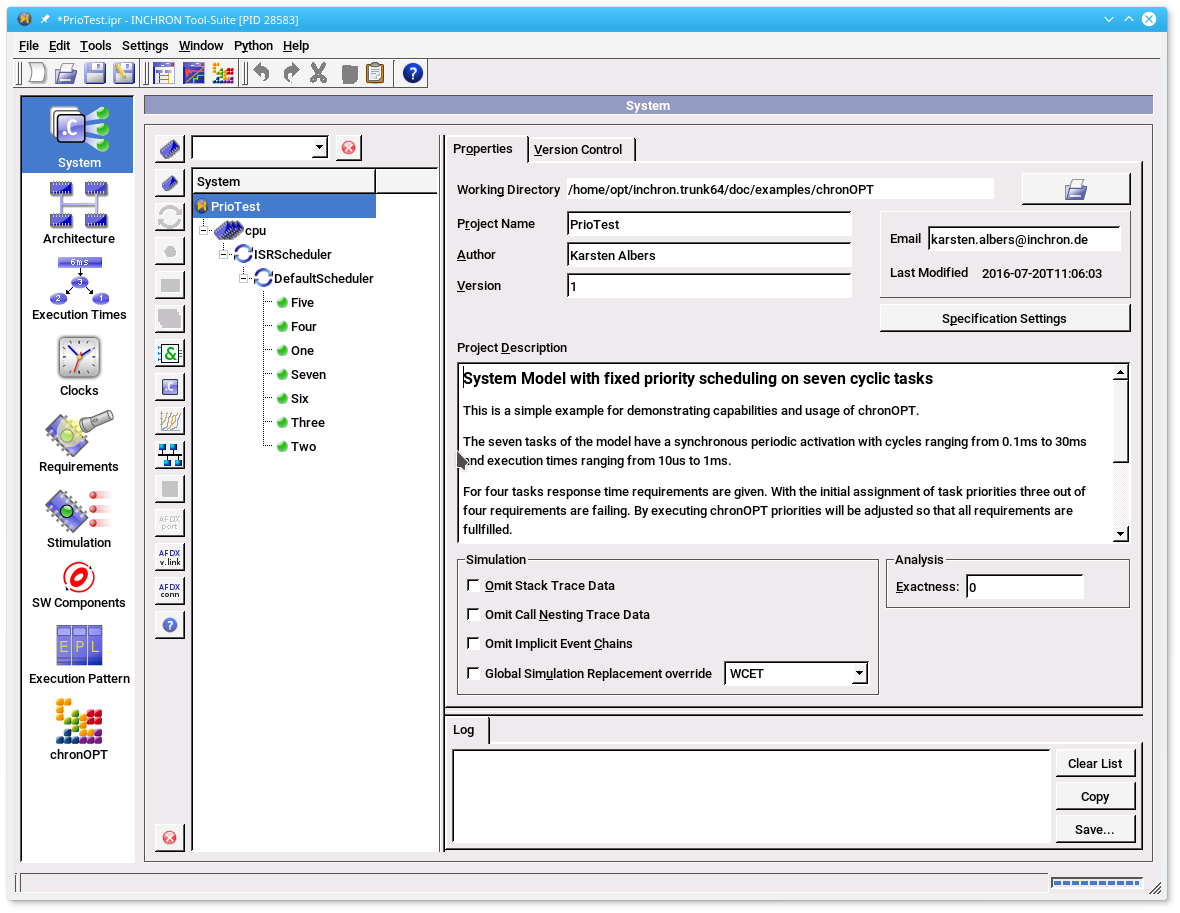

- 9.1 System Model of chronOPT example PrioTest.ipr

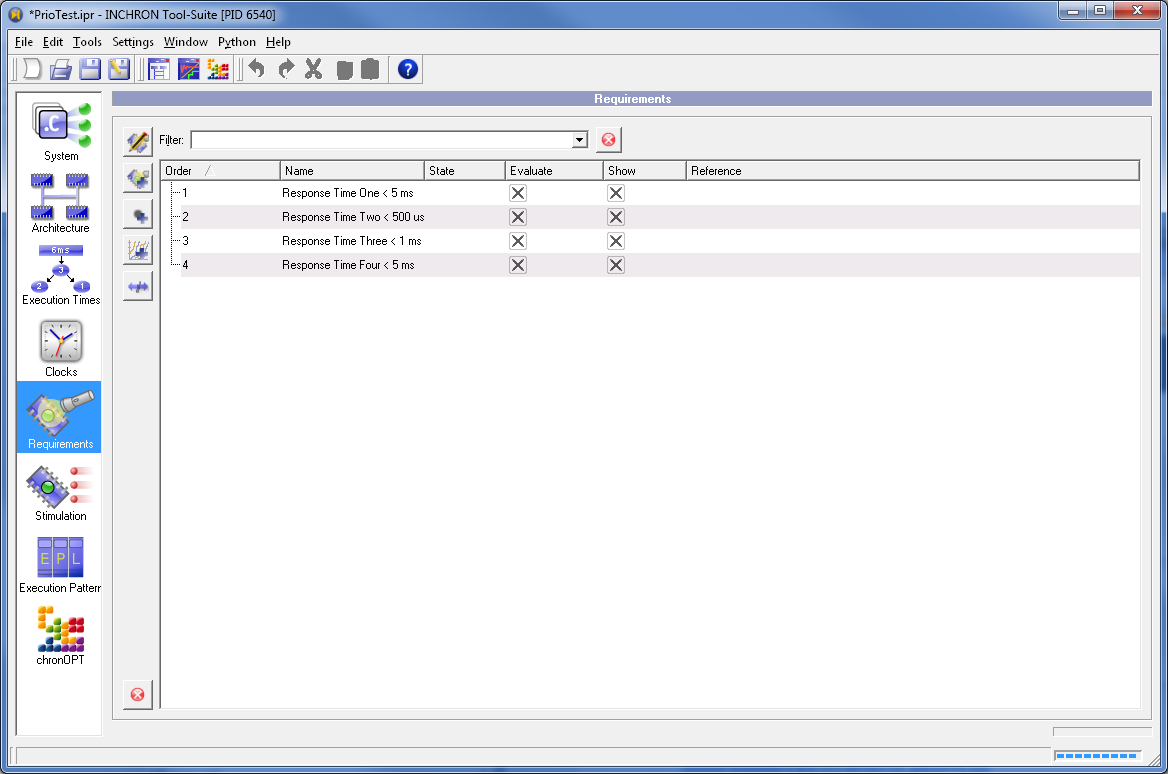

- 9.2 Real-Time Requirements for chronOPT example PrioTest.ipr

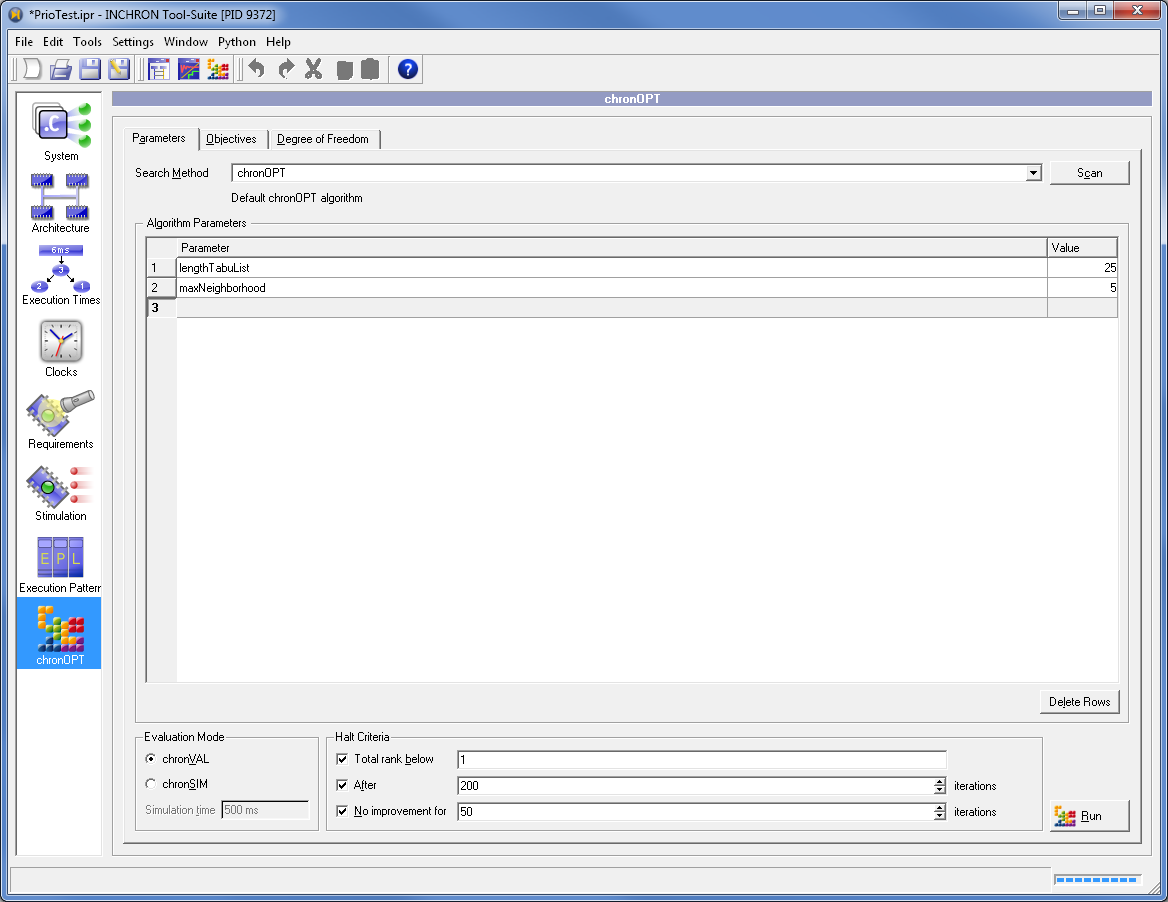

- 9.3 chronOPT Parameters tab of chronOPT example PrioTest.ipr

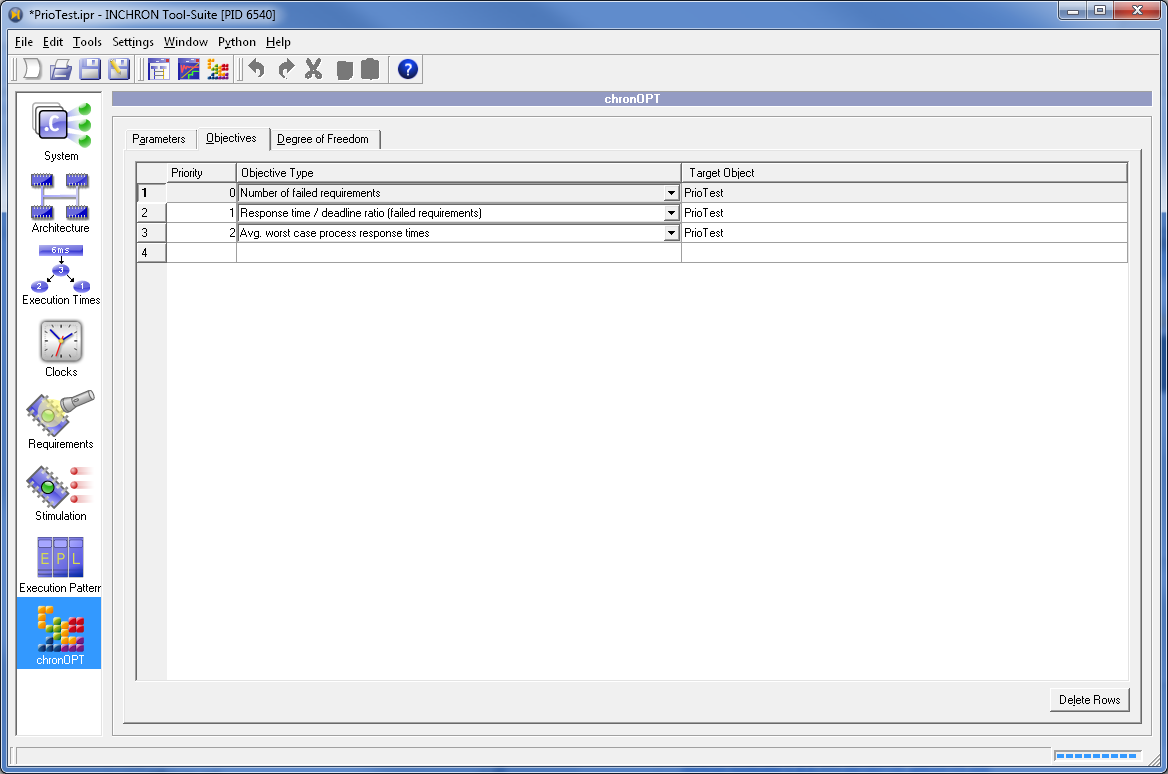

- 9.4 Objectives of chronOPT example PrioTest.ipr

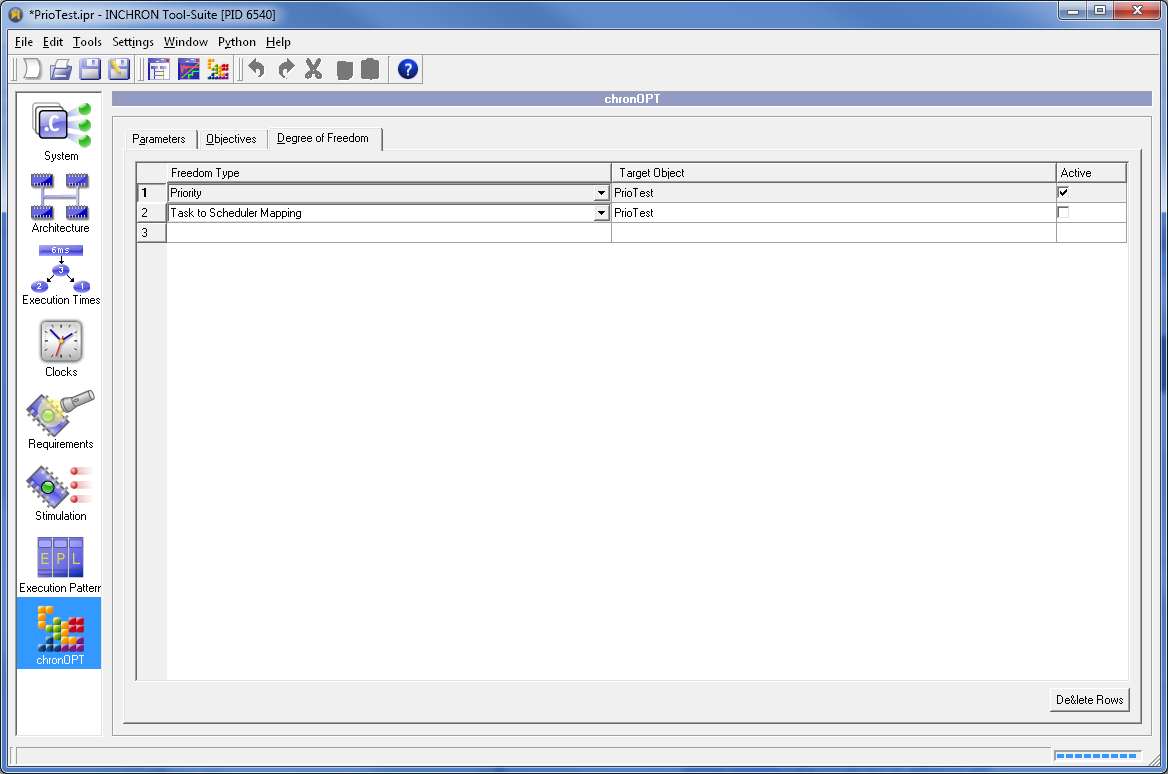

- 9.5 Degree of Freedom of chronOPT example PrioTest.ipr

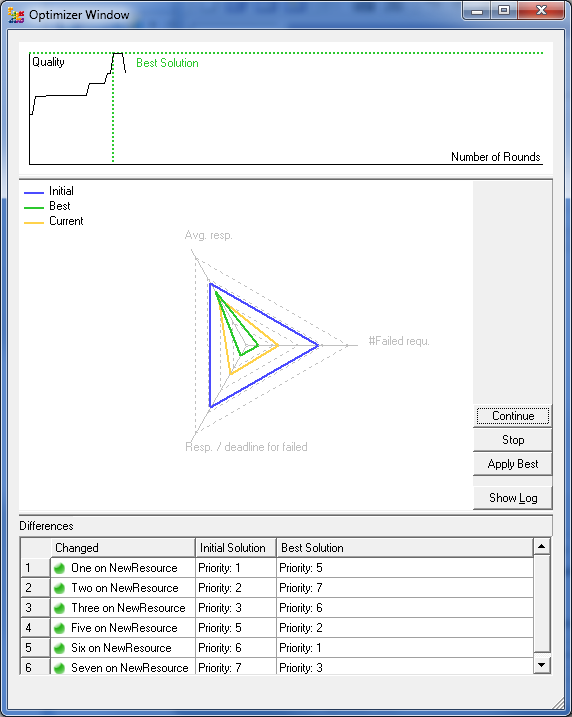

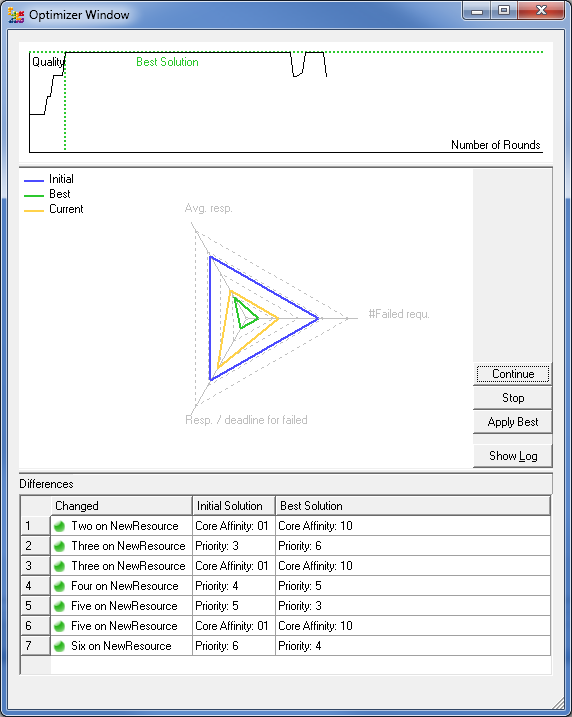

- 9.6 Optimizer Window for chronOPT example PrioTest.ipr

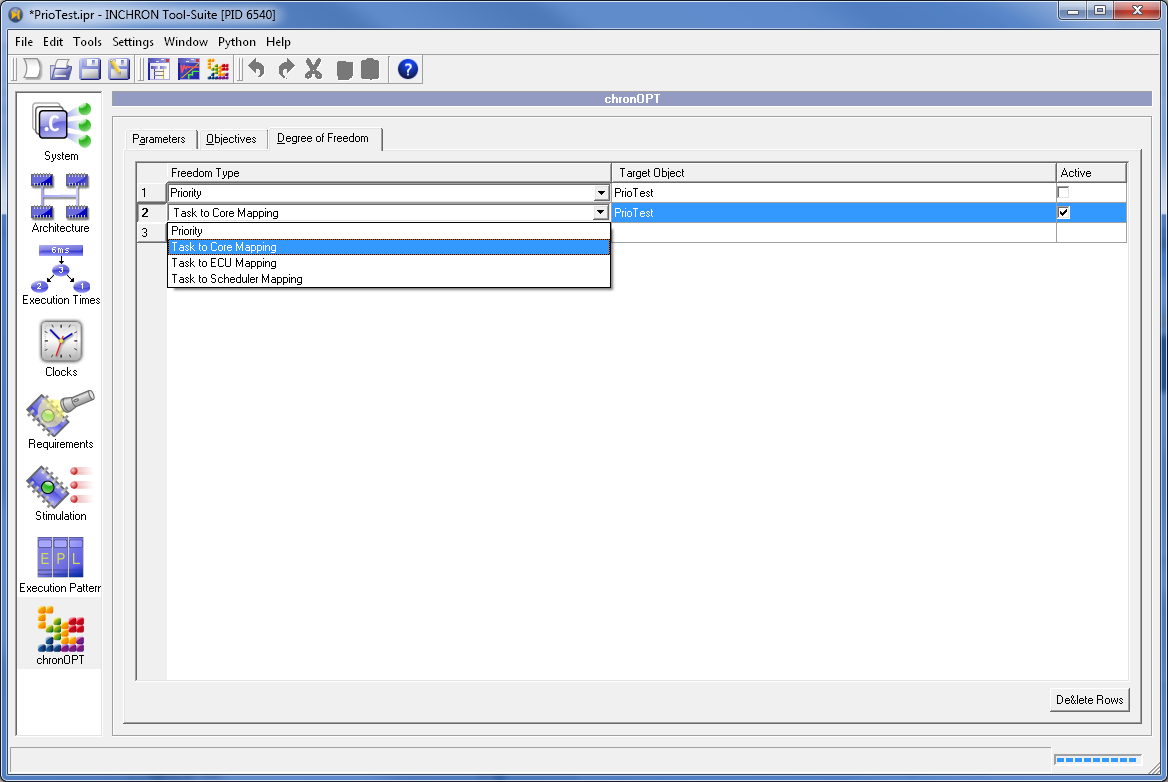

- 9.7 Degree of Freedom for Task to Core Assignment

- 9.8 Optimization Progress for Task to Core Assignment

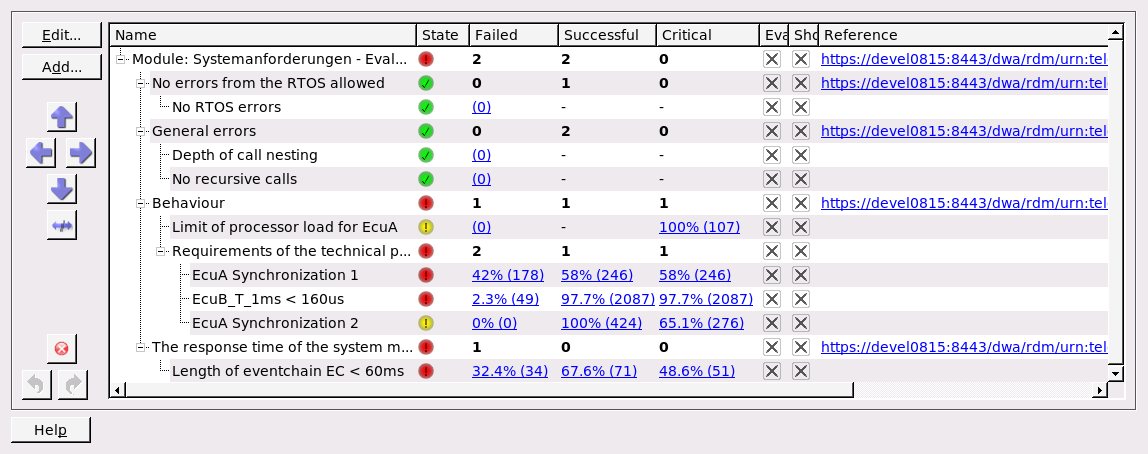

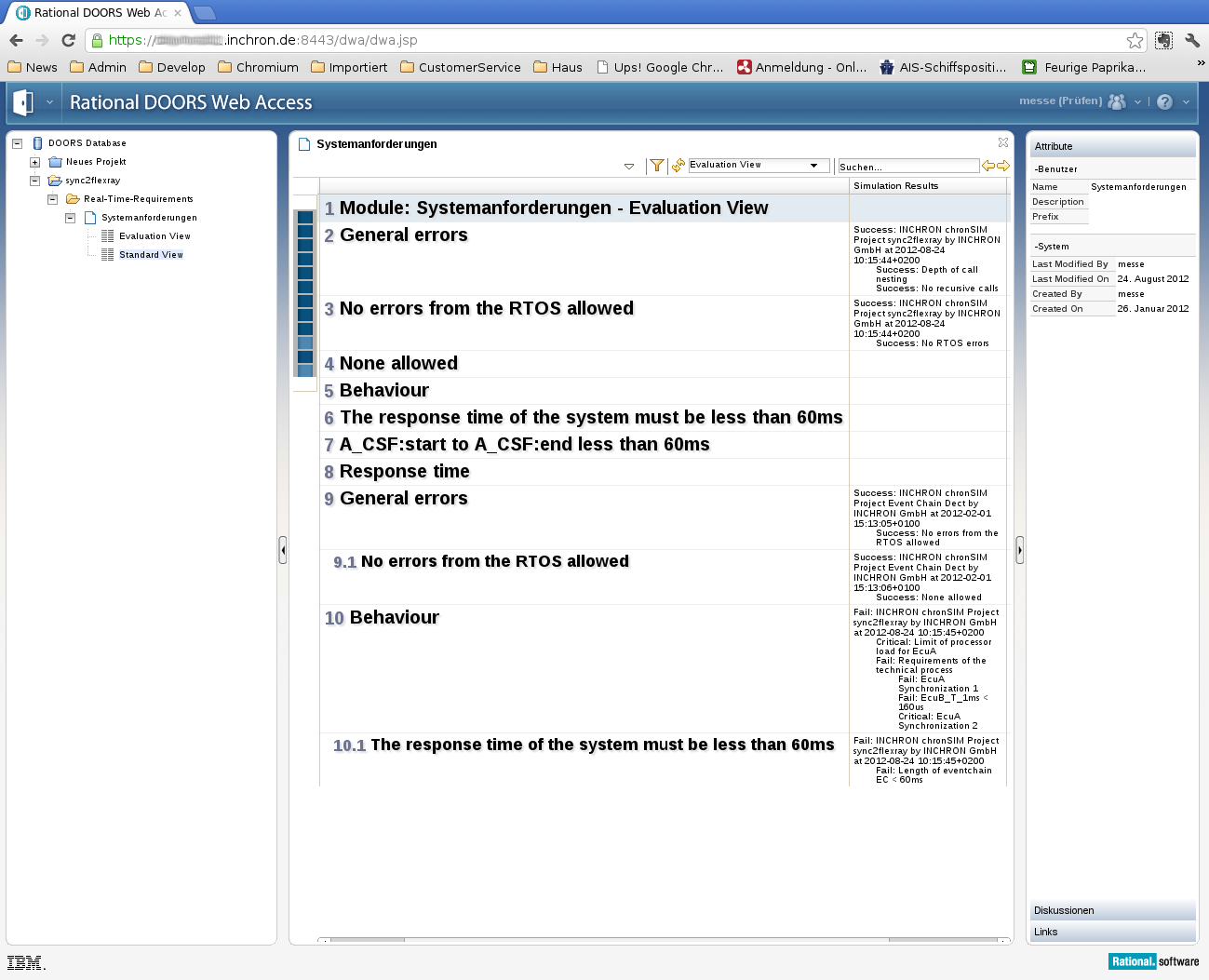

- 11.1 Requirement evaluations after import from DOORS and refinement

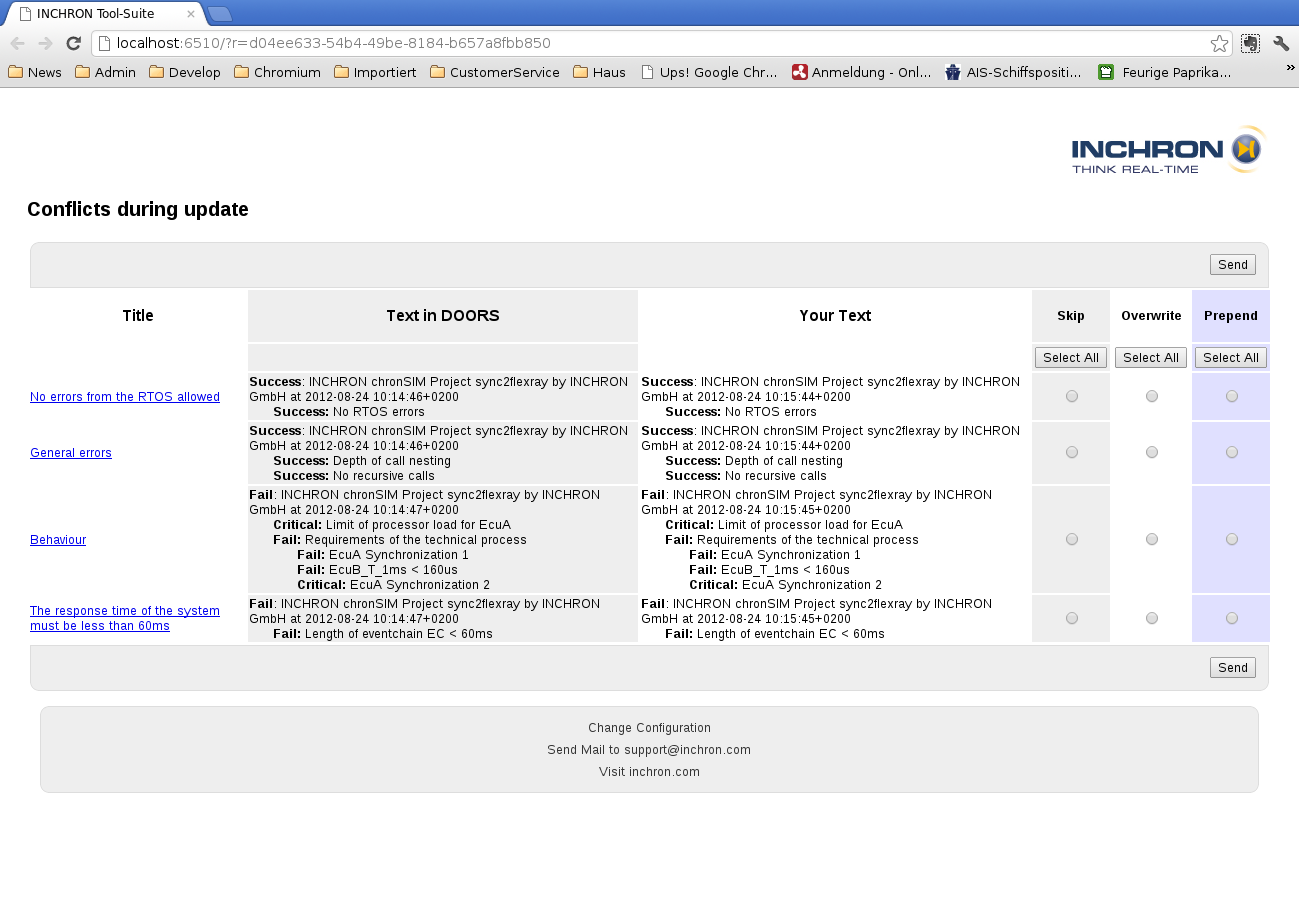

- 11.2 Conflicting changes detected during export to DOORS

- 11.3 Status page shown after successful export to DOORS

- 11.4 Viewing the requirements in the DOORS Web Access

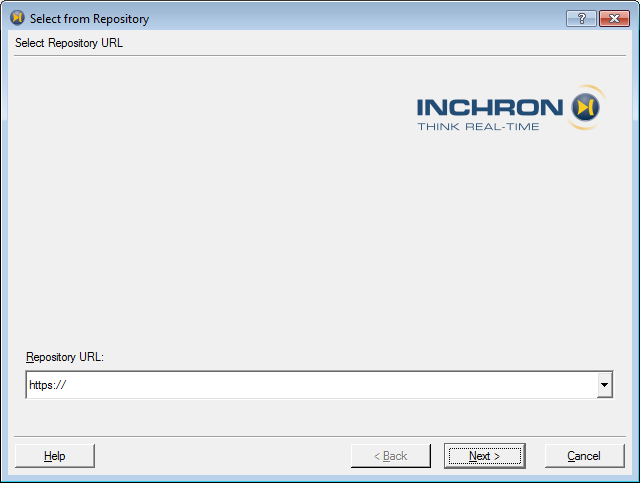

- 12.1 Repository Wizard

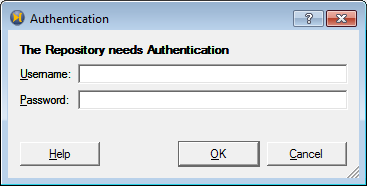

- 12.2 Repository Authentication

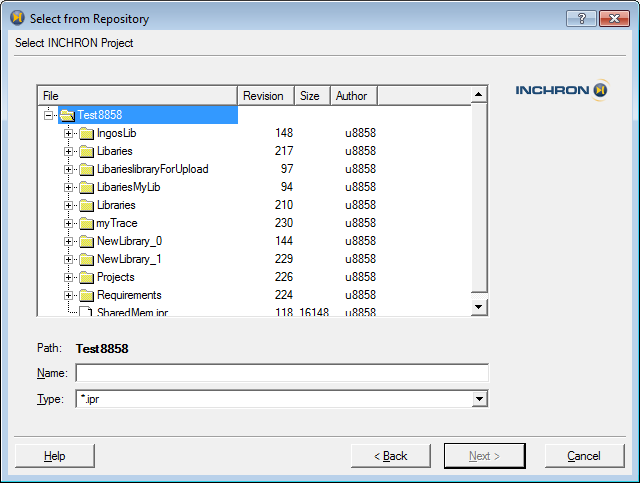

- 12.3 Repository Wizard

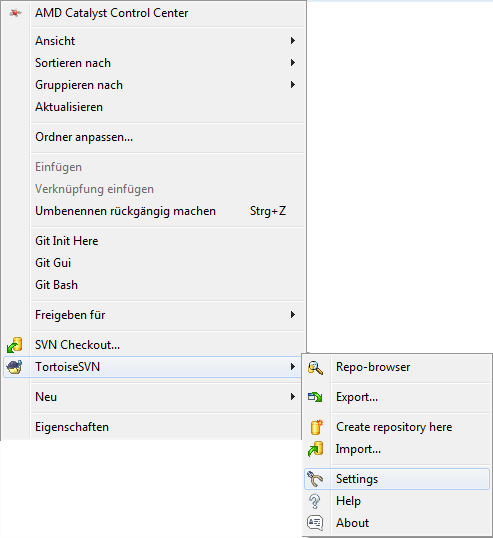

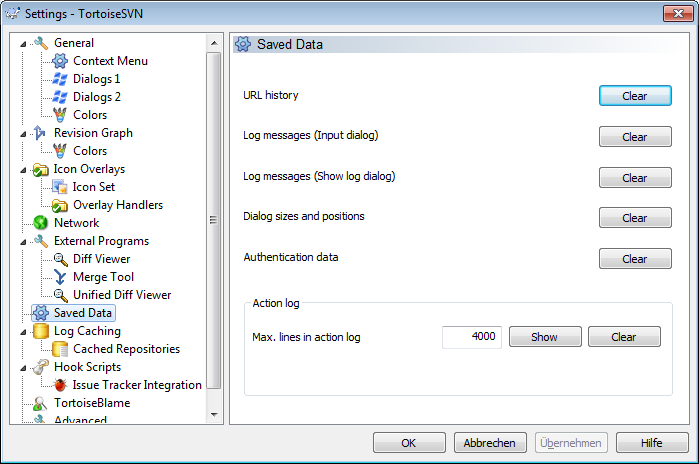

- 12.4 Access TortoiseSVN Settings

- 12.5 TortoiseSVN Settings

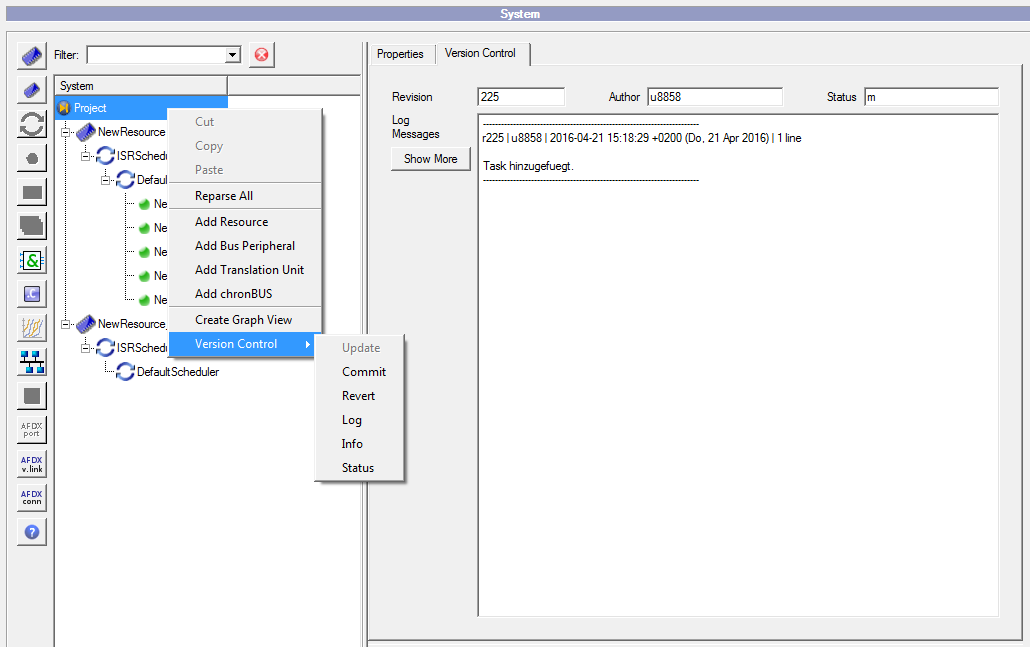

- 12.6 Version Control Information

Copyright Notice#

Copyright © 2006-2018 INCHRON GmbH, Germany

No part of this document may be reproduced, transmitted, processed or recorded by any means or form, electronic, mechanical, photographic or otherwise, translated to another language, or be released to any third party without the express written consent of INCHRON GmbH.

The development of the underlying technology of the INCHRON Tool-Suite was funded by financial means of the Ministry of Economics of the State Brandenburg and the European Union. The responsibility for the content is solely with the authors.

Printed in Germany.

Disclaimer Notice#

The information contained in this document is subject to change without notice. INCHRON shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material. INCHRON expressly disclaims all responsibility and liability for the installation, use, performance, maintenance and support of third party products. Customers are advised to make their own independent evaluation of such products.

INCHRON, Task Model, chronSIM, chronEST, chronOPT and chronVAL are registered trademarks of INCHRON.

Microsoft Windows, Windows 2000, Windows XP, Windows 7 and Windows 8 Windows 10 are registered trademarks of Microsoft Corporation. Adobe, Acrobat and the Acrobat logo are trademarks of Adobe System Incorporated Inc., which may be registered in certain jurisdictions. IBM Rational DOORS and IBM Rational Rhapsody are registered trademarks of International Business Machines Corporation. Other products and company names mentioned herein may be trademarks and/or registered trademarks of their respective owners.

This product contains GNU GPL licensed code, which is available at request from INCHRON.

For more information: Contact your local INCHRON representative for more information on any of the products mentioned in this manual.

Karl-Liebknecht-Str. 138

D-14482 Potsdam

Germany

https://www.inchron.com

e-mail <info@inchron.com>

phone +49 (331) 2797892-0

fax +49 (331) 70488599

1 Introduction #

This chapter will give you an overview of the aim and purpose of INCHRON Tool-Suite. In particular, the following questions will be answered:

What is INCHRON Tool-Suite?

Who are the typical users of INCHRON Tool-Suite?

What are the typical applications of INCHRON Tool-Suite?

What is the benefit of INCHRON Tool-Suite?

Which optional add-ons are available for INCHRON Tool-Suite?

What should I do if the integrated component library does not list my intended target platform?

Please pay close attention to the Section 1.6, “Disclaimer”.

For any questions about INCHRON Tool-Suite refer to <support@inchron.de>. For each customer the INCHRON website (www.inchron.com) provides a personal support login (https://www.inchron.de/110.html) where updates of INCHRON Tool-Suite are made available.

1.1 What is INCHRON Tool-Suite #

The INCHRON Tool-Suite is a MS Windows based application which is employed in the development of embedded systems. It is an integrated design, diagnosis and test tool for the simulation, analysis and in-depth prediction of the dynamic behavior of embedded software. INCHRON Tool-Suite enables you to analyze both the functional and dynamic behavior of your complete or yet incomplete C source code on a virtual prototype. INCHRON Tool-Suite factors your embedded system’s hardware architecture as well as its operating system and compiler.

1.1.1 The INCHRON Tool-Suite as Design-Tool #

Software and hardware architecture is determined by „what-if“ analyses during system design. Comparing design alternatives in no time provides the ability to design a system architecture which still fulfills all of its real-time requirements. Beyond that, conclusions about execution times on tasks, function and code segment level can be drawn, which can be incorporated into a design specification for subsequent developments.

1.1.2 The INCHRON Tool-Suite as diagnostic and test tool #

The INCHRON Tool-Suite supports you in analyzing the dynamic behavior and helps you to validate the design specifications of your software. Test methodology intended for release tests can be employed throughout the whole software development life cycle. This enables you to locate and eliminate dynamic flaws and performance bottlenecks at an early stage and thereby validate and optimize your software yet before building a prototype.

1.2 Typical Users of INCHRON Tool-Suite #

The INCHRON Tool-Suite is typically used by the following user groups:

System engineers use INCHRON Tool-Suite during the design phase of embedded systems for finding the optimal system architecture.

Development engineers use INCHRON Tool-Suite during the development stage for analyzing and optimizing the dynamic behavior of embedded software or selected software modules.

Testing engineers use INCHRON Tool-Suite during the test stage for the validation of the dynamic behavior in order to verify the real-time capabilities of the embedded system.

The INCHRON Tool-Suite is intended for experts so that users of INCHRON Tool-Suite should be skilled in an appropriate occupation, e.g. electrical engineering or computer science. Theoretical basics of and practical experience with embedded systems and the C programming language are essential preconditions for an effective application of INCHRON Tool-Suite.

If you require special training on INCHRON Tool-Suite and embedded systems, please contact your INCHRON Tool-Suite partner.

1.3 Typical Fields of Application #

The INCHRON Tool-Suite is typically employed in the following application fields:

1.3.1 Designing Embedded Systems #

In many projects, the degree of freedom to design HW is limited and consequently the main emphasis is put on software design. Hence, engineers want to find the optimum software architecture (definition of tasks and interrupt service routines, scheduling, etc.) while being limited in adapting the HW architecture. Even though the focus is on the software architecture, changes in the HW architecture, like different size of memory and a different microprocessor within a given processor family, etc., require thorough investigation in order to find the most cost-effective solution.

System Engineers use INCHRON Tool-Suite for system design by performing what-if analyses combined with in-depth investigations to make design decisions on software architecture taking into account different underlying hardware architectures. Before the real code is written, engineers assign execution time budgets to tasks, functions and code segments of the intended software structure to simulate and analyze the dynamic behavior of different software architectures until engineers have designed the most suitable software architecture. Moreover, system engineers make well-founded decisions on execution time requirements of tasks, functions and code segments as design input data to avoid real-time problems.

1.3.2 Analysis and Test of Embedded Software #

During software coding, engineers replace more and more time budgets of the initial software architecture with coded software modules. INCHRON Tool-Suite executes these modules on a virtual prototype whereby chronEST automatically calculates the execution time of these software modules considering the hardware architecture. Thus, engineers are able to perform an in depth analysis of the dynamic behavior of embedded software, investigate and avoid potential runtime problems as well as optimize and verify the system before building a real prototype. Simulating the design under stress conditions quickly reveals bottlenecks and shows the amount of resources remaining for future software expansions. The performance can be analyzed early without having a real prototype.

1.3.3 Reuse of Legacy Code #

Very often, engineers jump-start development projects by reusing software from previous projects. As a result, engineers want to quickly analyze the re-usability of legacy code and to assess the R&D efforts to adapt such legacy code to be used within new applications. INCHRON Tool-Suite in combination with chronEST perfectly addresses these issues. For new products, engineers design a new software architecture, which includes the legacy code. While simulating such “hybrid” software architectures, engineers can quickly assess the reusability of code. Further more, engineers get a deep insight into the dynamic behavior of legacy code.

1.3.4 Extensibility of Embedded Software #

In a fast changing environment, products need to be quickly modifiable to implement new higher valued features. As a result, engineers have to make fast feasibility studies in order to economically assess the R&D efforts for implementing a new feature. Using INCHRON Tool-Suite and chronEST, engineers can quickly integrate their estimated execution time of a new feature into the current software architecture of the embedded system. Thus it is possible to analyze the impact of a new feature in the dynamic behavior of the total embedded system, even before writing the appropriate software code. Such an analysis of utmost importance since a new feature may negatively impact the execution time of other features resulting in a non-real-time-compliance embedded system.

1.4 Benefits of Using INCHRON Tool-Suite #

INCHRON Tool-Suite enables you to identify and eliminate design faults, which brings about the following cogent advantages:

1.4.1 Reduced Time to-Market #

INCHRON Tool-Suite helps to reduce the number of redesign cycles by enabling system engineers to analyze, optimize and verify the design very early during development even before a real prototype is built. Less redesign cycles, directly reducing the time-to-market and simultaneously improving the chances of attaining the targeted market launch date.

1.4.2 Reduced R&D Spendings #

By employing INCHRON Tool-Suite, engineers can analyze and optimize a design without being forced to build a prototype, thus reducing redesign cycles. Avoiding project delays and improving time-to-market have a direct impact on the R&D cost.

1.4.3 Reduced Product Cost #

INCHRON Tool-Suite simulates embedded software on different hardware architectures, enabling engineers to select the most cost effective design.

1.4.4 Reduced Risk of Product Recall #

INCHRON Tool-Suite increases the quality of embedded systems by avoiding real-time problems. Engineers can detect and eliminate real-time problems at the development stage and thereby dramatically reduce the risk of product recalls.

1.4.5 Impact of New Product Features #

When confronted with new requirements, engineers have to make a fast estimation of the impact of new features. With INCHRON Tool-Suite, engineers can integrate the requirement of a new feature into the original system specification to analyze and predict the impact without building a prototype. INCHRON Tool-Suite provides a prompt answer to the question whether a new feature can be integrated into the existing design or whether a major redesign is necessary.

1.5 Optional Tool-Suite Addons #

1.5.1 Option chronSIM #

The behavior of the defined system can be examined with the optional module chronSIM in a simulation. The INCHRON Tool Suite represents the reaction of the embedded system to the given stimulation in detail. A special emphasis is the investigation of the task behavior and the tracking of data flows and event chains by the system.

1.5.2 Option chronVAL #

The optional module chronVAL examines the embedded system analytically. The adherence to given real time requirements is calculated for the worst case. Innovative patent protected procedures are used to consider the run time behavior of the tasks, the dependence among themselves and the worst possible suggestion.

1.5.3 Option chronOPT #

The optional module chronOPT facilitates automatic tuning of different kinds of system model parameters in order to adjust its real-time behavior regarding certain real -time requirements.

1.5.4 Option chronBUS #

For the simplified modeling of complex systems and also for the acceleration of simulation a part of a large system can be replaced by the chronBUS in the INCHRON Tool Suite. To communication buses attached controllers are reduced thereby to their communication behavior.

1.5.5 Option chronAFDX #

With this option the INCHRON Tool-Suite supports the modeling of AFDX networked systems. Virtual links can be defined and AFDX Message can be modeled. The resulting system can be examined with chronSIM and chronVAL.

1.5.6 Option chronEST #

In chronSIM the execution times of code blocks have to be entered manually. chronEST allows the execution times to be determined automatically from your partial or complete source code, factoring both the architecture of the target processor (register set, pipeline architecture etc.) as well as optimizations done by compilers.

1.5.7 Additional Target Platforms #

INCHRON Tool-Suite comes along with an extensive library of target platforms (microprocessors, real-time operating systems, etc.). This library is continuously maintained and extended by INCHRON. Please contact your INCHRON Tool-Suite partner if the integrated library does not support your intended platform.

1.6 Disclaimer #

There are no understandings, agreements, representations, or warranties either expressed or implied, including warranties of merchantability or fitness for a particular purpose, other than those specifically set out by any existing contract between the parties. Any such contract states the entire obligation of the seller. The contents of this technical manual shall not become part of or modify any prior or existing agreement, commitment, or relationship.

1.6.1 Warranties #

The information, recommendations, descriptions, and safety notices in this technical manual are based on INCHRON experience and judgment with respect to operation and maintenance of the described product. This information should not be considered as all–inclusive or covering all contingencies. If further information is required, INCHRON GmbH, should be consulted.

No warranties, either expressed or implied, including warranties of fitness for a particular purpose or merchantability, or warranties arising from the course of dealing or usage of trade, are made regarding the information, recommendations, descriptions, warnings and cautions contained herein.

1.6.2 Limitation of Liability #

In no event will INCHRON be responsible to the user in contract, in tort (including negligence), strict liability or otherwise for any special, indirect, incidental, or consequential damage or loss whatsoever, including but not limited to: damage or loss of use of equipment, cost of capital, loss of profits or revenues, or claims against the user by its customers from the use of the information, recommendations, descriptions, and safety notices contained herein.

2 Installation #

The Tool-Suite's user interface follows the standard Windows look & feel. The installation of the INCHRON Tool-Suite requires knowledge of the Windows operating system. The user interface of the INCHRON Tool-Suite is in English language.

The INCHRON Tool-Suite comes on an installation CD-ROM together with this user manual. In case of a WIBU-KEY license a hardware dongle is enclosed. If a FLEXlm license is used no dongle is required. In case any of the aforementioned parts are missing in your delivery, please contact your Tool-Suite distribution partner.

Throughout this manual

user input is indicated with key,

menu choices are represented as → →

alternative activation via toolbar buttons is indicated with the corresponding

icon aside the text.

icon aside the text.

2.1 System Requirements #

INCHRON Tool-Suite's single license is designed to be installed on workstations or notebook computers. With a floating license INCHRON Tool-Suite can be used via a local area network or any other Internet connection as well.

2.1.1 Hardware Requirements #

INCHRON Tool-Suite is designed to run on standard x86-based PC hardware. In order to run INCHRON Tool-Suite, your computer must meet the following minimum requirements:

at least

512MB RAM,1024MB recommendedx86-64 based processor with

1.4 GHzor aboveat least

1.5 GBof free hard disk spacea CD-ROM drive in case of CD installation

a graphics adapter with at least 256 colors and a screen resolution of

1152 x 864pixel or abovea free USB connector in case of a WIBU-KEY license -or- a network card with TCP/IP protocol (floating license only)

2.1.2 Operating System Requirements #

INCHRON Tool-Suite requires Microsoft Windows XP in German or English language with Service Pack 2 installed or alternatively Microsoft Windows 7, 8 or 10.

For displaying control flow graphs the external software GraphViz is used. Absence of these 3rd party software packages does not impair proper operation of INCHRON Tool-Suite, but will only affect the displaying and printing of graphs. These 3rd party software packages can be installed directly from your INCHRON Tool-Suite CD-ROM.

2.2 Software Installation #

The INCHRON installation CD has been designed to start INCHRON Tool-Suite installation routine automatically when you insert the CD-ROM into your CD-ROM drive. To prevent the INCHRON Tool-Suite installation from starting up, hold the shift key until your operating system has recognized the CD-ROM.

2.2.1 Installation #

Before installation terminate any WIBU-KEY-Server already running e.g. with the context menu of the WIBU icon in the task-bar

Insert the installation CD into the CD-ROM drive.

The Installation starts automatically and checks the integrity of the CD data. Proceed with step 5 if the installation starts automatically. Proceed with the following steps if the installer does not start automatically.

Figure 2.1: The INCHRON Tool-Suite Setup is Being Loaded #

Run the installer Setup.exe from the CD, e.g. via → → .

Select the of your CD-ROM, Setup.exe and confirm with and .

After the verification has finished start the installation with or abort with .

The installation routine checks the software environment of your computer.

Figure 2.2: INCHRON Tool-Suite Installation Question #

A welcome window displays recommendations for the installation. Click to continue.

Figure 2.3: INCHRON Tool-Suite Setup Welcome Page #

-

Read the INCHRON Tool-Suite's license agreement carefully. If you agree with the terms and conditions of this license, click .

You cannot install INCHRON Tool-Suite if you do not agree with the terms and conditions of this license.

In this case cancel the installation with .

Figure 2.4: INCHRON Tool-Suite Software License Agreement #

-

If you accept the license agreement, setup will ask you which INCHRON Tool-Suite software components should be installed.

The default selection will install all available software components.

Figure 2.5: Selection of Software Modules for Installation #

Deselect all program modules that you do not need and want to be excluded from installation by ing the respective checkboxes.

Confirm your selection with .

In the next step you will be asked to provide an installation path for your INCHRON Tool-Suite installation. You can manually modify the default installation path by clicking .

A dialog appears for choosing a custom installation directory.

Figure 2.6: INCHRON Tool-Suite Installation Path #

Confirm your selection with .

INCHRON Tool-Suite setup has now collected all relevant information for installing INCHRON Tool-Suite.

Click .

The installation starts. You can observe the progress and all details of the installation on the screen. Please wait until all data is saved onto your hard disk. This may take several minutes.

Figure 2.7: Installation Progress #

-

After the installation of INCHRON Tool-Suite you will be asked to confirm the installation of 3rd party tools.

Figure 2.8: Installation of 3rd Party Tools #

-

Confirm with or abort the installation of 3rd party tools by clicking on .

Only the selected software modules will be installed. If you already have appropriate versions of the 3rd party tools installed on your computer, you will be asked if you want to re-install them.

Follow the installation instructions of the respective 3rd party tools installers.

To finish the installation click on .

Figure 2.9: The Installation is Complete #

If you selected the "License WIBU-Dongle" component in Step 8 the computer needs to restarted before using the Tool-Suite.

2.2.2 License Management #

The INCHRON Tool-Suite comprises different tool options namely chronSIM, chronVAL, chronEST, chronBUS, chronVIEW, chronOPT and chronView which may be used separately. The usage of any of these tool options requires a license option. The license may be available either as USB dongle or FLEXlm license. In both cases single-seat as well as network licenses are possible.

The configuration of a license server and the management of licensing options to be used is done with the Manage Licenses dialog from within the INCHRON Tool-Suite. Server license allocation may be limited by restricting any workstation to a single instance of the Tool-Suite application see Section 4.4.1, “General Settings”). Changing the current set of INCHRON Tool-Suite tool license options is done as follows:

Start the INCHRON Tool-Suite with → → → .

In case no simulation or validation license is configured the Manage Licenses dialog will appear. Otherwise

Select → .

The Manage Licenses dialog shows up.

Figure 2.10: Manage Licenses Dialog #

Select the appropriate tool options , , and press .

The License available will be shown if the selected options are covered by your license server or license dongle.

the dialog and restart the INCHRON Tool-Suite.

In case you selected the option chronVIEW only, INCHRON Tool-Suite will directly start in simulation mode instead of project mode.

2.2.3 License Management with WIBUKEY Systems #

2.2.3.1 Separate Installation of Dongle Software #

In case INCHRON Tool-Suite is configured to use the WIBU-KEY Systems license mechanism all license information is stored on an USB dongle. By default the dongle software is installed during the INCHRON Tool-Suite installation. However, you may also install the dongle software separately.

This is done as follows:

Close all other running applications.

Terminate any WIBU-KEY-Server already running e.g. with the context menu of the WIBU icon in the task-bar

Double-click SETUP32.EXE from the

WibuKeyfolder on the INCHRON Installation CD.Follow the instructions on the screen.

The installation program displays the identified operating system and lists all files required for the dongle.

Clicking will copy and install all listed files onto your hard disk.

-

If you encounter an error during the installation, you should restart your computer and start again from a).

After successful installation a new folder

WIBU-KEYcan be found in → .

INCHRON Tool-Suite automatically checks on every start for the dongle and the dongle software. With a "single license" the dongle is required to be connected to your computer's USB connector when INCHRON Tool-Suite is running. With a floating license the dongle software should be installed onto a separate constantly available computer in your network. In order to use your floating license the dongle must remain in the USB connector of the separate computer. Accessing the floating license may be restricted by a firewall. In such a case, please contact your system administrator.

2.2.3.2 Configuration of a License Server #

In the Manage Licenses dialog you may configure a network license server instead of using a local license dongle. To select a network license server do as follows:

Select → .

The Manage Licenses dialog appears.

Figure 2.11: Manage Licenses Dialog #

-

Check the Local License checkbox if you have plugged the INCHRON USB license dongle directly into your computer's USB port.

If you have a INCHRON license server in your local area network or on the Internet, enter the server's hostname or its IP address into the Server input field.

Click on .

INCHRON Tool-Suite checks if there is a license dongle connected to your PC or if the license server is available. If successful, the status will change to License available.

Figure 2.12: Valid WIBU-KEY License #

In case searching the license was not successful, check if your license server is running and the network is up and/or the license dongle is plugged in correctly. Then repeat steps 2 and 3

INCHRON Tool-Suite periodically checks for the license dongle or its connection to the license server when running. In case the license check fails, the license manager dialog appears and the Tool-Suite is paused. If the license check failure was only due to a temporary glitch, the dialog will automatically disappear and INCHRON Tool-Suite will continue with normal operation.

In a network license environment the license server must be

constantly available for proper operation of the INCHRON Tool-Suite.

Make sure that legitimate users can access port

22347 (TCP and UDP) on your license server.

We strongly advise you to protect your license server from

unauthorized access by making use of a firewall.

Please find more information on how to run a network license server in the windows start menu under → → → .

2.2.4 License Management with FLEXlm #

Alternatively to using a USB dongle the Flexera FLEXlm® license mechanism may be used. A FLEXlm® license is bound to the host ID of your computer or the network server respectively. The FLEXlm licensing mechanism requires no additional Flexera software to be installed on your computer.

2.2.4.1 Selection of The License Mechanism #

In order to switch to the FLEXlm® licensing mechanism select → from the menu. In the Manage Licenses dialog (s. Figure 2.13, “Manage Licenses Dialog with Activated FLEXlm License”). Check the Flexera License Manager (FlexNet Publisher) option.

Figure 2.13: Manage Licenses Dialog with Activated FLEXlm License #

2.2.4.2 Installation of The License File #

The FLEXlm® licensing

mechanism requires a LIC

license file in the license

subdirectory of the INCHRON Tool-Suite installation directory. The

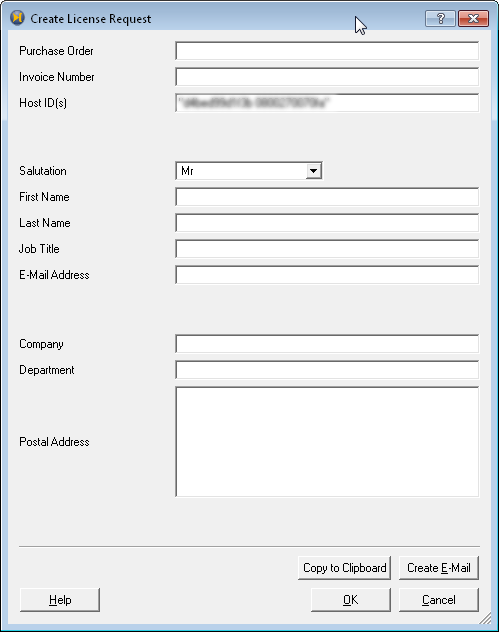

license file can be obtained by clicking on Request

License.... It opens a dialog which already contains

your Host ID. You have to add your invoice number and your address.

The buttons Copy to Clipboard or

Create E-Mail both create the content of an

email which you can send to <license@inchron.de>. For

this purpose your configured email tool is started, the Tool-Suite

does not send any emails on its own.

Figure 2.14: Request License Dialog #

Another way to request a license is as follows:

Use the windows start menu to open the command shell.

Change to the folder

licenseof your INCHRON Tool-Suite installation.Invoke the program lmhostid.exe.

The host ID of your computer will be queried and displayed.

Send the Host ID together with the number of your INCHRON Tool-Suite invoice to <license@inchron.de>.

INCHRON will send you a license file which has to be stored in the

licensefolder of your INCHRON Tool-Suite installation.Restart the INCHRON Tool-Suite.

2.2.4.3 Usage of a License Server #

The FLEXlm® license mechanism may also be used with a network or floating license. For this you need a license file on your license server, which has to be copied to each client installation.

First use the lmhostid.exe application to get the server host ID and request a server license file from INCHRON as described in the previous section.

Copy this license file together with the program inchrond.exe to the license server.

On each client copy the same license file to the

licensefolder of your INCHRON Tool-Suite installation.Restart the INCHRON Tool-Suite.

In order to use a network license the license server must be running and connectable by the client.

2.2.5 Selection of Tool Options #

In large installations it is common that a company acquires a different number of licenses for e.g simulation (chronSIM), validation (chronVAL), and trace analysis only (chronVIEW). In such a case it is important that each installation of INCHRON Tool-Suite occupies only the required tool license options.

The selection of required license options can be changed as follows:

Select the menu → .

The Manage Licenses dialog opens (s. Figure 2.12, “Valid WIBU-KEY License”).

In the lower part of the dialog is a set of checkboxes for the tools. Select the licenses you want to use.

The license is requested immediately and the result is displayed.

Close the dialog.

If you change from or to trace analysis (chronVIEW) you have to restart the INCHRON Tool-Suite for the changes to become effective.

When started chronVIEW comes up with the Simulator Window. There you can import trace files immediately. This function is also contained in chronSIM. Thus for comparison of simulation results with measured traces once in a while you do not need to change the license options every time.

2.2.6 Verifying your Installation #

The installation verification is exemplified with an example project.

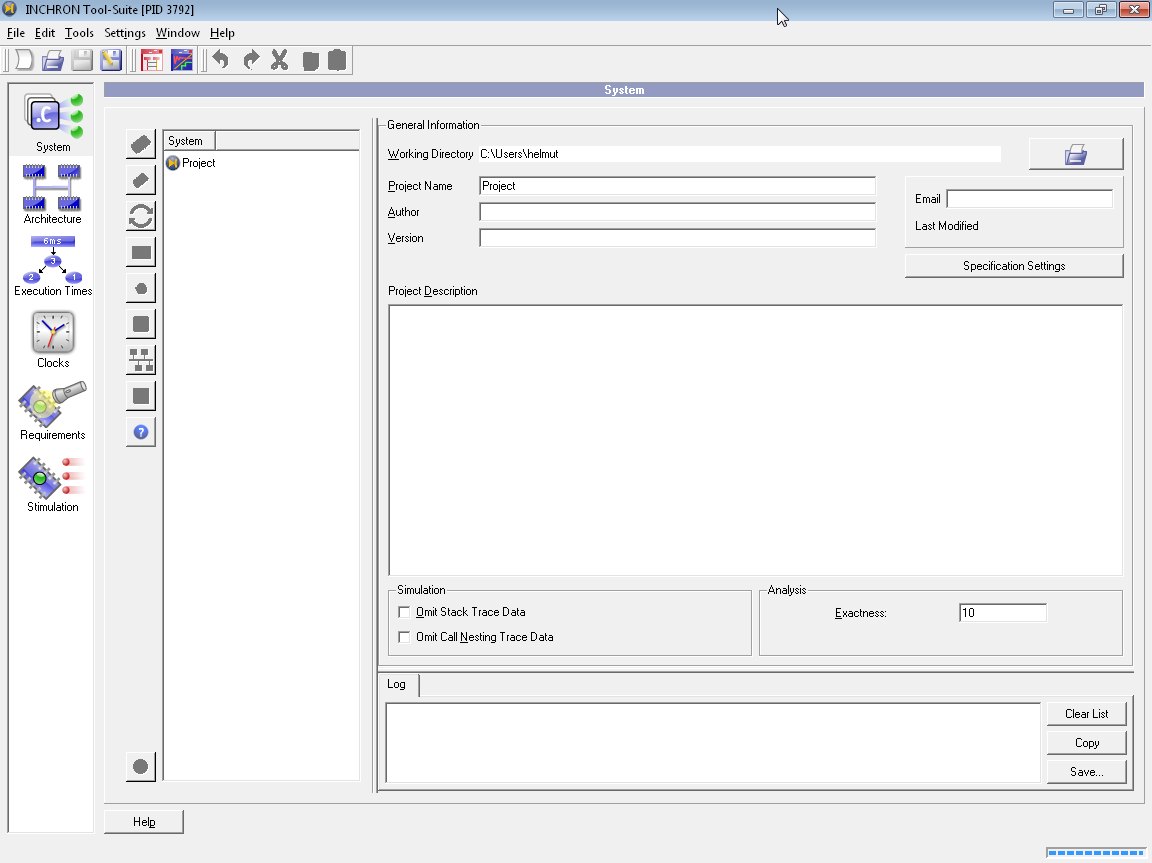

Start the INCHRON Tool-Suite with → → → .

INCHRON Tool-Suite splash screen will shown and the Tool-Suite starts in project mode.

Figure 2.15: INCHRON Tool-Suite Project Window #

From the menu choose → .

The file open dialog for example projects appears.

Open the

dectsubdirectory and select thedect.iprproject file.Confirm with .

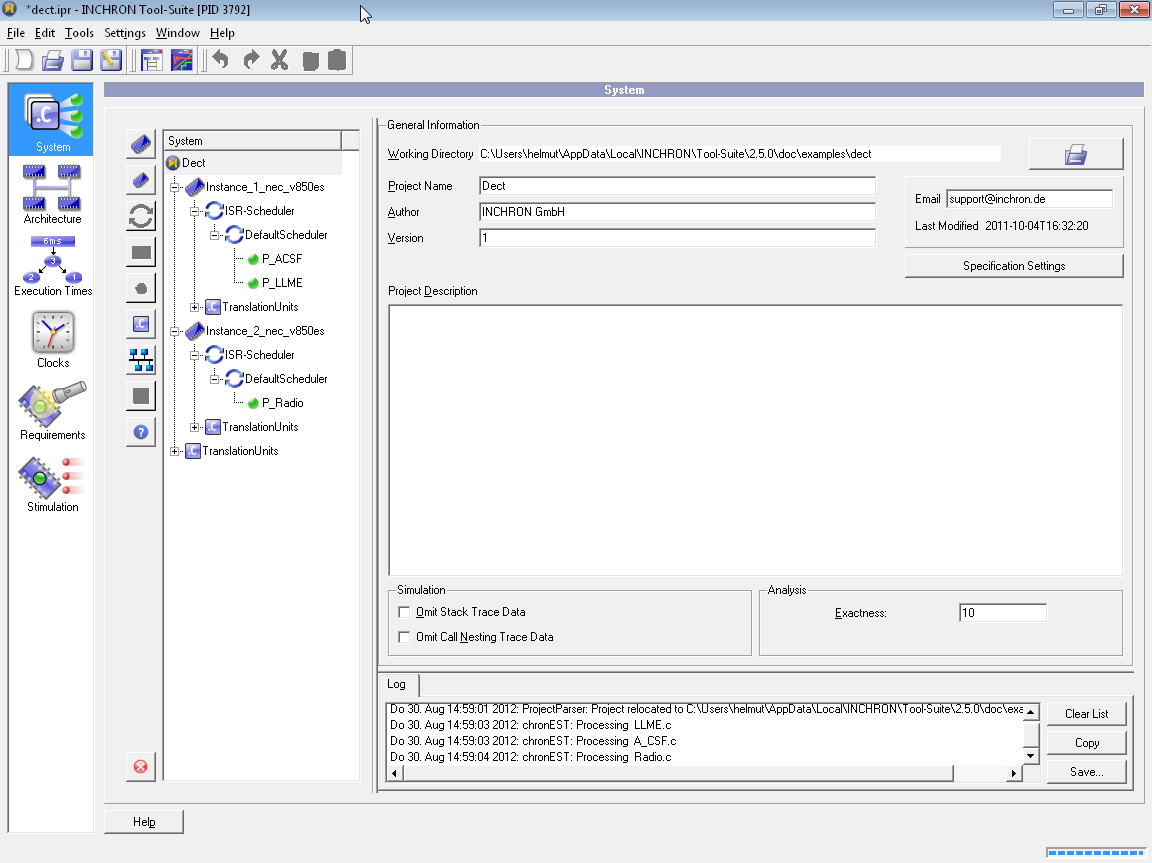

Figure 2.16: INCHRON Tool-Suite Project Window with Example Project #

-

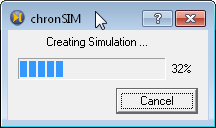

During preparation of the simulation a progress dialog is displayed.

Figure 2.17: Progress Dialog During Simulation Preparation #

After generation of the executable simulation model the INCHRON Tool-Suite Real-Time Simulator window opens.

Figure 2.18: INCHRON Tool-Suite Real-Time Simulator Window #

If the generation of the simulation fails you will be notified with an error pop-up window.

Figure 2.19: Simulation generation failed #

In this case you should uninstall INCHRON Tool-Suite and repeat the installation procedure. If the re-installation does not succeed contact your contractual partner.

-

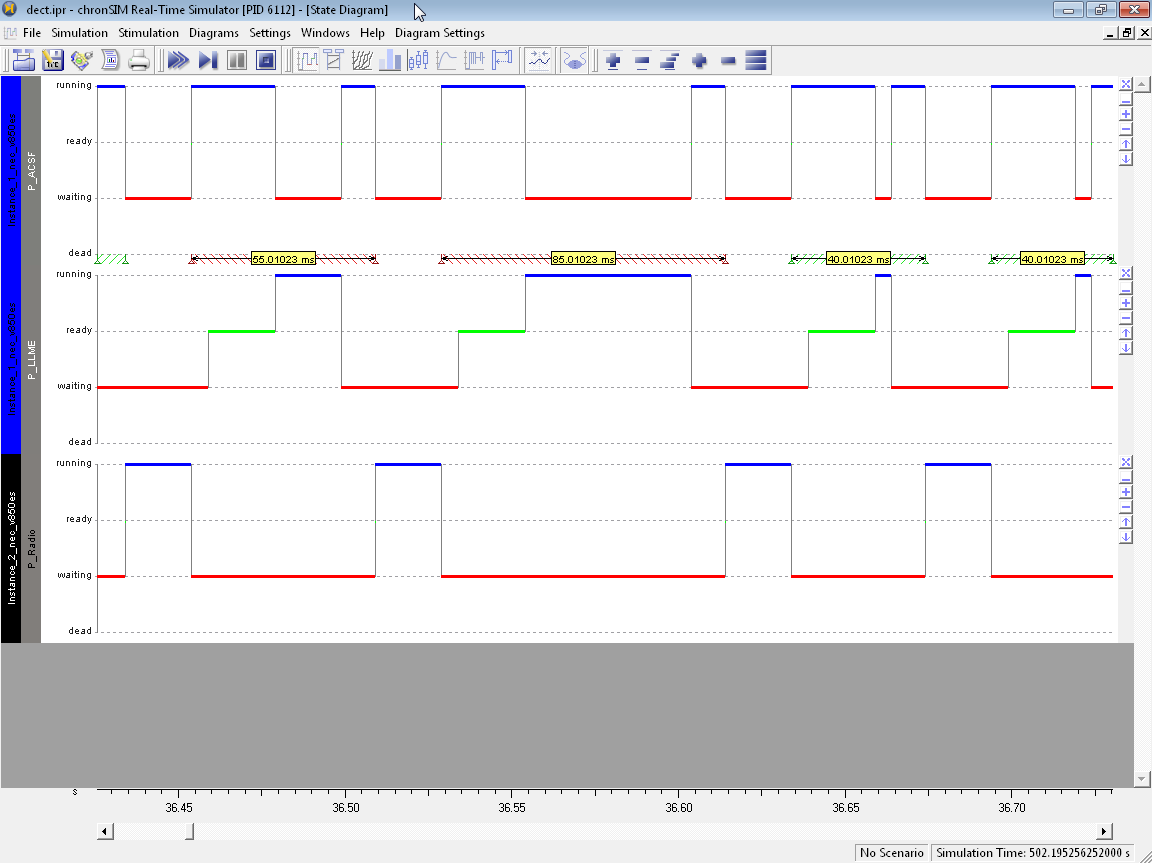

An (empty) State Diagram window opens.

-

The State Diagram window will show a timeline of processor states as x/t diagram x/t diagram. If necessary adjust the vertical of timescale with the and buttons in the toolbar.

Figure 2.20: State Diagram Window During Simulation #

By successfully simulating an example project the installation of the INCHRON Tool-Suite is verified.

Terminate the simulation with → .

Close the INCHRON Tool-Suite Real-Time Simulator window with → .

Terminate the INCHRON Tool-Suite with → .

2.3 Configuring Python Scripting Support #

Python scripting support for system models comes as an extra software package (which is contained in the regular Tool-Suite installation).

After installing the INCHRON Tool-Suite follow the following procedure to install python support:

-

Download and install the latest release of python 2.7 from the python.org download site" (https://www.python.org/downloads/)

-

Open the

addonsdirectory of the Tool-Suite installation. -

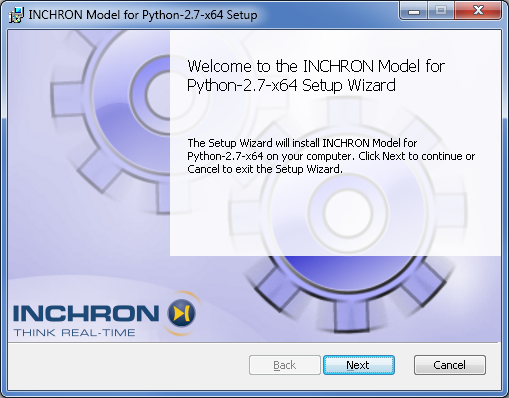

Run the MSI installer called

inchron-model.Figure 2.21: Install wizard for the INCHRON Tool-Suite Python Addon #

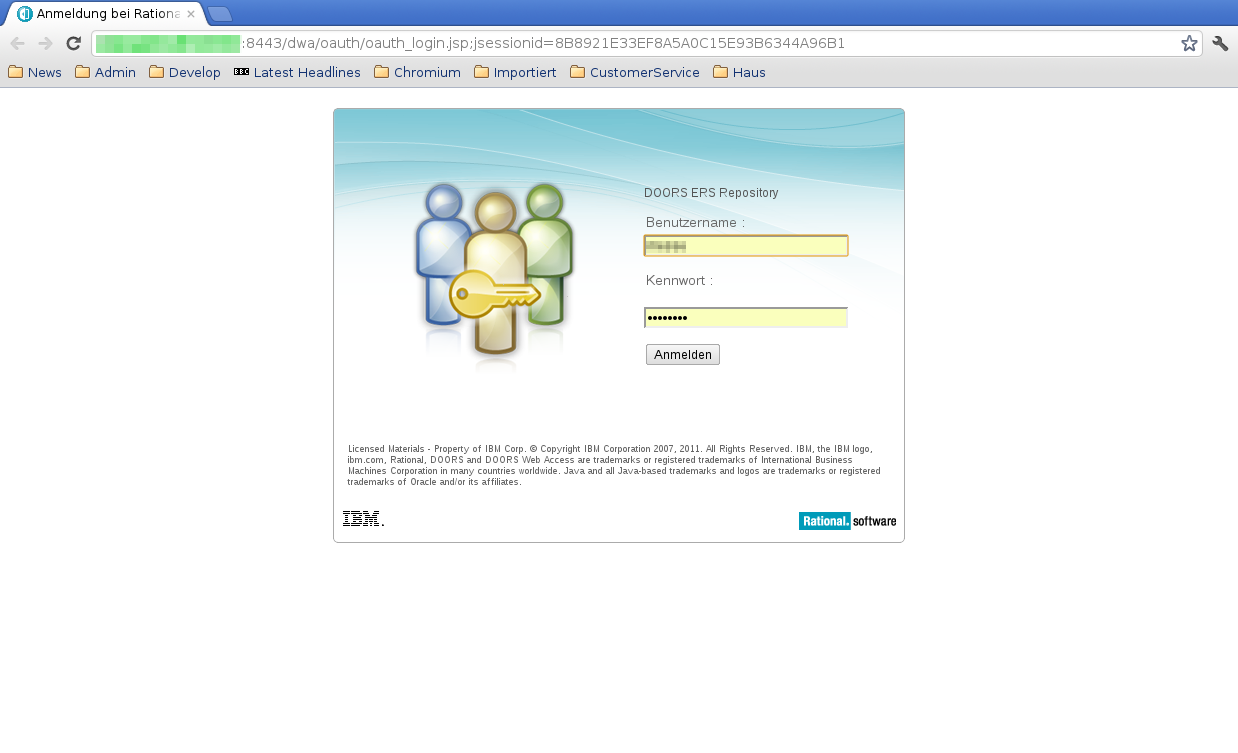

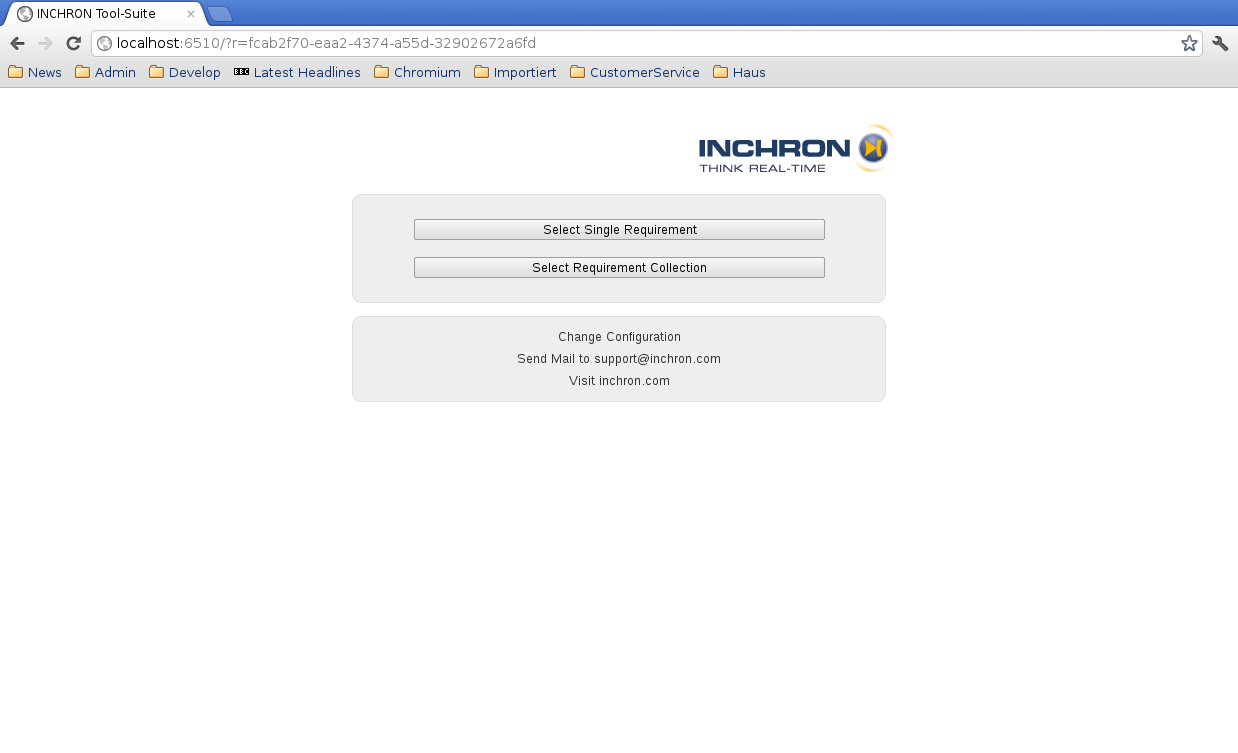

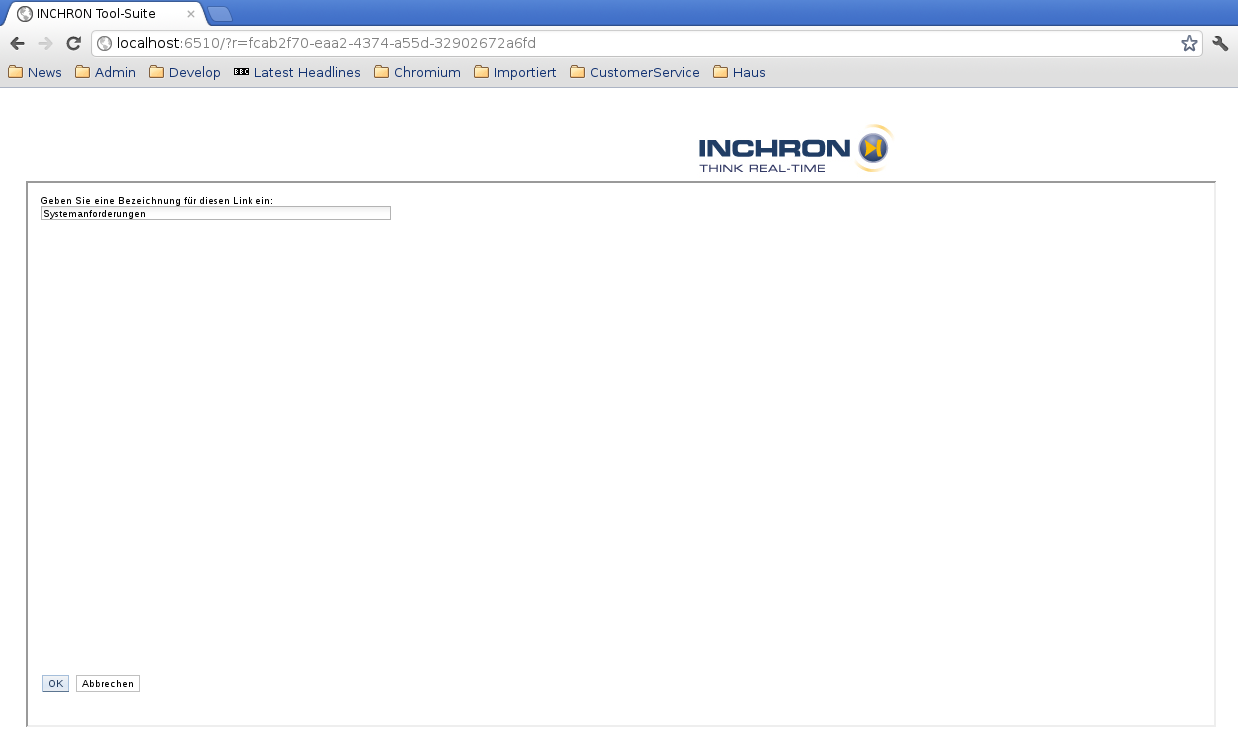

2.4 Configuring the IBM Rational DOORS Integration #

The INCHRON Tool-Suite has built-in support to connect to an IBM Rational DOORS server and to import and export requirements from and to the DOORS database.

The connection to the DOORS database as well as the attribute mapping must be configured to match the DOORS server configuration. The procedure, the mechanism for deploying a predefined configuration, and the prerequisites for the integration itself are described in the following sections.

2.4.1 Prerequisites #

The connection to the DOORS database is based on Open Services for Lifecycle Collaboration (OSLC). It supports Requirements Management (RM), version 1.

IBM Rational DOORS offers this interface via the DOORS Web Access (DWA). The Tool-Suite requires at least DOORS 9.3.0.4 and DOORS Web Access 1.4.0.4. The following sections assume that these DOORS components have been installed. Additionally administrative permissions on the DOORS database are required for configuration.

2.4.2 Configuration #

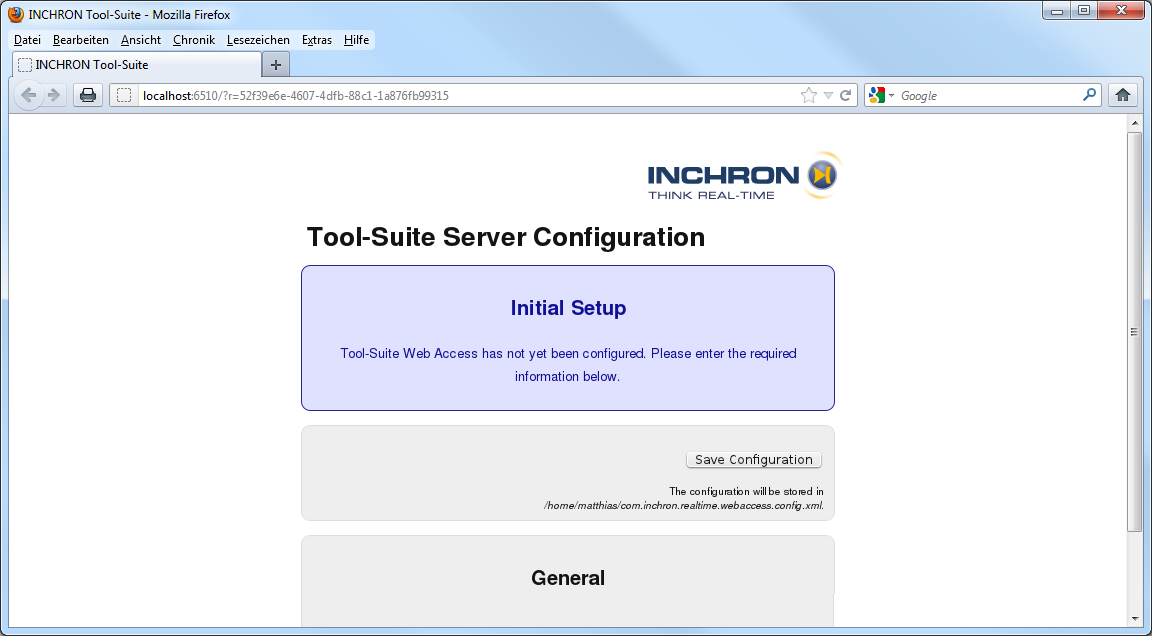

The INCHRON Tool-Suite OSLC integration can be configured using a web browser. Select → to start the configuration. On an unconfigured system the Initial Configuration Page will also be shown when selecting any other DOORS-related operation.

Figure 2.22: The Initial Configuration Page #

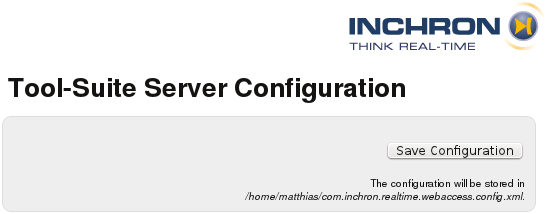

At the top and the bottom of the page a Save Configuration button is located. It stores the actual values to an XML encoded file.

Figure 2.23: The top section of the Configuration Page #

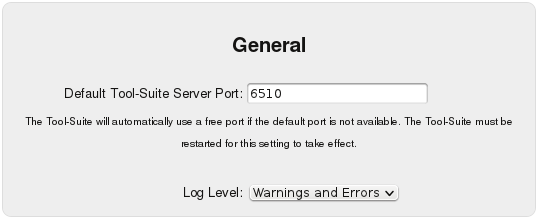

The OSLC based connection to the DOORS database is a two-way

communication. Therefore the Tool-Suite also opens a local TCP port and

listens for connections. In the General section

this port can be configured. The port is only reachable from localhost.

The Log Level can be configured. All messages are shown in the Log Messages Window of the Tool-Suite.

Figure 2.24: The General section of the Configuration Page #

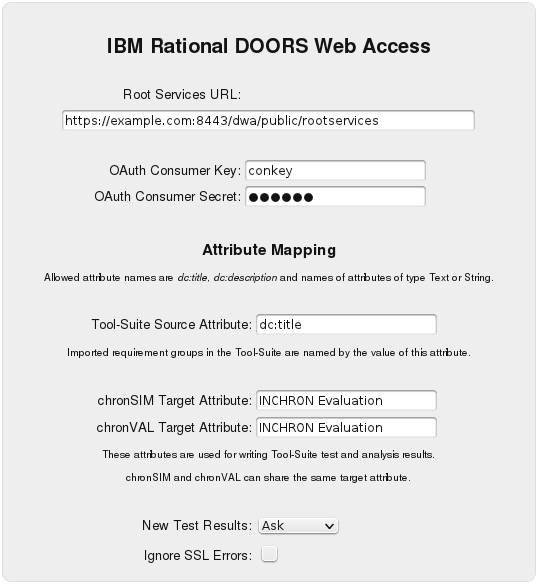

The connection to the DOORS database has to be configured in the DOORS Web Access section. The options are:

-

The Root Services URL identifies the connection point to the DOORS database. Usually it contains the scheme

https://, a hostname, a port and the path component /dwa/public/rootservices. The hostname can be a fully specified hostname, a local hostname, or an IP address. The port number is defined by the configuration of the DOORS database with the default being 8443. Ask your DOORS administrator for the actual values. Valid examples are:https://doors.example.com:8443/dwa/public/rootserviceshttps://localhost:8443/dwa/public/rootserviceshttps://10.10.17.42:8443/dwa/public/rootservices

-

In addition to the user credentials the INCHRON Tool-Suite has to authenticate itself as a registered application for the DOORS database. For this purpose the OAuth Consumer Key and the OAuth Consumer Secret are used. Enter the same values here which you have registered in the DOORS database.

-

The name for an imported requirement is taken from the attribute specified in the Tool-Suite Source Attribute field. The default is

dc:title. -

In the same way the name of the attributes can be specified where the chronSIM and the chronVAL results are written into. These fields have to be added by the DOORS database administrator before they can be used. The same value is allowed for the chronSIM Target Attribute and the chronVAL Target Attribute. If this is the case the results are either overwritten or prepended according to the strategy selected for New Test Results.

-

The dropdown-box New Test Results defines the strategy which is used when results are exported to DOORS and there is already a result from earlier simulations or analyses. You can change between Overwrite (keeps only the last result), Prepend (the last result is the first paragraph) or Ask (which requires user interaction).

-

Ignore SSL Error: Continues the import and/or export process even in the case of errors during the SSL handshake. Otherwise the error is shown and the process is canceled.

Figure 2.25: The DOORS Web Access section of the Configuration Page #

At the bottom of the configuration page the Save Configuration button is repeated. Hyperlinks provide access to the INCHRON Support and to the INCHRON web site.

Figure 2.26: The bottom section of the Configuration Page #

2.4.3 Deploying a Predefined Configuration #

The configuration of the connection to the DOORS database can be shared by multiple users by performing the following steps:

-

Install the Tool-Suite and start it as an ordinary user.

-

Edit the IBM Rational DOORS Settings (see Section 2.4.2, “Configuration”).

-

Save the configuration settings.

A file

com.inchron.realtime.webaccess.config.xmlis created in the directory%USERPROFILE%. -

Copy the file

com.inchron.realtime.webaccess.config.xmlto the installation directory of the INCHRON Tool-Suite. This is one level aboveSuite.exe.

Now every user running this Tool-Suite installation will use the set configuration.

2.5 Uninstall INCHRON Tool-Suite #

To uninstall INCHRON Tool-Suite follow the instructions below:

-

Exit the INCHRON Tool-Suite.

Save all your simulation results and project files on an external drive. Make sure to preserve the folder structure.

Start the software management panel by clicking → → and select Software.

The list of installed programs appears.

Select INCHRON Tool-Suite from the list.

Figure 2.27: Windows Deinstallation Window #

Click on and follow the instructions on the screen.

These programs may be removed separately with → → → → → .

2.6 Re-install INCHRON Tool-Suite #

After deinstallation the INCHRON Tool-Suite may be re-installed with the same procedure as on initial installation.

3 Basics #

The following chapter gives you a brief introduction in the structure and handling of INCHRON Tool-Suite.

3.1 INCHRON Tool-Suite Features #

The term system architecture is always regarded as the view on the target system. An INCHRON model of the target system consists of:

The number and type of microprocessors

The wiring of processors in multiprocessor systems

The (real-time) operating system in use

The mapping of tasks on processors

The mapping of runnables on tasks

The selection of scheduling methods and strategies

The assignment of task and interrupt priorities

The specification of external peripherals like interrupt inputs, parallel ports and communication interfaces.

The modeling of external stimulation.

All these aspects of an embedded system are edited with the graphical model editor of the INCHRON Tool-Suite. Interoperability with external models is provided with OSEK OIL, DBC, FIBEX and AUTOSAR import features. The creation and manipulation of system models may also be scripted using the inchron python modeling API.

The optional component chronSIM connects the functional simulation of the source code of your embedded system with the analysis of execution times of the real target system by chronEST. The optional component chronVAL allows the analysis of real-time capabilities. To achieve this, the user has to specify various aspects of the target system using the modules of the INCHRON Tool-Suite GUI.

The module system shows a unified view of the system models hardware and software. Microprocessors are defined to be mapped to processes or tasks and source files.

Based on this information and with aid of the optional chronEST component the INCHRON Tool-Suite will estimate static execution times of functions and processes. Estimated execution times may be overridden individually by the user

The purpose of module architecture is to define the hardware mappings between microprocessors and communication controllers and buses. Thereby the communication relations between microprocessors are defined

In a multiprocessor system each processor has its own view of time, a clock triggered by its quartz. A major feature of the INCHRON Tool-Suite is that the simulation with chronSIM takes into account all effects of deviating local times due to different drifting microprocessor clocks. For that purpose parameters like granularity and the drift or range of values are specified for each clock individually.

The objective of chronSIM simulation and chronVAL validation with the INCHRON Tool-Suite is to asses whether a given system meets specific requirements under different scenarios of external stimulation. If this is not the case INCHRON Tool-Suite allows to analyze the causes for requirement violations and provides a means to evaluate system model variants without the need of prototypes in real hardware.

Real-time requirements like response times and functional requirements like stack limits are defined within INCHRON Tool-Suite and requirement violations are indicated in the simulation diagrams.

A chronSIM simulation can be stimulated in flexible ways with different stimulation scenarios. The module stimulation of the Tool-Suite allows for configuration of stimulation scenarios ranging from simple periodic signals to complex scenarios with mutual dependencies and stochastic generators or even with recorded data from field tests.

For chronSIM simulation the definitions and configurations of the system model are compiled into an independent simulation executable. The resulting simulation model is executed under the control of a timed event-driven simulator. All simulation times recorded and displayed in the various diagrams show real execution times of the target system and have no relation to any execution times on the simulation host.

Due to the compiled simulation the simulation runs much faster than e.g. the interpretation of each instruction of the binary code.

3.2 INCHRON Tool-Suite Modes of Operation #

INCHRON Tool-Suite uses three different modes of operation and an additional viewer only mode:

Project Mode

The project mode is in fact the INCHRON project editor which allows to define all aspects of the system model used by the INCHRON Tool-Suite components chronEST, chronSIM, chronBUS and chronVAL

Simulation Mode

The simulation mode simulates and analyzes the target system based on the project settings and its configuration.

Validation Mode

Provides chronVAL validation of the target system by means of chronVAL.

Viewer-Only Mode

A restricted (chronVIEW) license which allows for viewing and analysis of existing simulation traces with diagrams and histograms of the simulation mode.

Each of the first three INCHRON Tool-Suite modes uses a separate application main window. The viewer-only mode uses the same window as the simulation mode. For a better understanding of the following descriptions you may want to start the INCHRON Tool-Suite. After starting the application with → → → the INCHRON Tool-Suite project mode window will appear.

3.2.1 The Project Mode #

In project mode the INCHRON Tool-Suite window is presented as main window for user interaction. It presents different views for editing different aspects of a system model. A detailed description of features of the project mode is subject to Chapter 6, System Modeling.

Figure 3.1: The INCHRON Tool-Suite project mode window #

3.2.1.1 The Project Mode Modules #

The editing of a system model is divided into separate modules. Each module is represented by its own icon. All module icons are vertically arranged on the left side of the project mode window. Each module can be activated by ing module's respective icon which will show the modules input masks.

3.2.1.2 Module System: Overall Model View #

This module shows the system models hardware and software components a system tree and allows adding, removing and editing of the components.

See Section 6.2, “Module System” for a detailed description.

3.2.1.3 Module Architecture: Hardware Components and Connection Matrix #

Shows a hardware view of the system tree. Allows for editing of the system's microprocessor and hardware communication interfaces their peripheral components and the connections of peripheral ports.

See Section 6.3, “Module Architecture” for a detailed description.

3.2.1.4 Module Execution Times: Estimated Processor Cycles #

Contains function and process execution times estimated with chronEST.

See Section 6.4, “Module Execution Time” for a detailed description.

3.2.1.5 Module Clocks: Processor Clocks #

This module comprises parameters of system clocks which define the individual time bases of the systems microprocessors and schedule tables of AUTOSAR systems.

See Section 6.5, “Module Clocks” for a detailed description.

3.2.1.6 Module Requirements: Conformance Criteria #

Definition of functional and real-time requirements for the specification conformance of the system. Real-time requirements are expressed as time budgets of e.g. processes, functions or processing steps. Criteria for functional requirements are e.g. function stack usage.

See Section 6.6, “Module Requirements” for a detailed description.

3.2.1.7 Module Stimulation #

Scenarios for external events and interrupts acting as input on the simulated system.

See Section 6.7, “Module Stimulation” for a detailed description.

3.2.2 The Simulation Mode #

The simulation mode requires the chronSIM license option and is entered by loading and compiling a simulation project from the project mode window. A detailed description of features of the simulation mode is subject to Chapter 7, Simulation. For a better understanding please open the example project from the INCHRON distribution:

Figure 3.2: chronSIM Real-Time Simulator window #

Together with the Real-Time Simulator window the Simulation Control window appears.

The purpose of the Simulation Control window is to enable of disable specific breakpoints. It may be toggled with → .

3.2.2.1 Functions for Simulation Control #

The basic functions for starting and stopping the simulation are available in the menu of the Real-Time Simulator window or with the buttons of the simulation control toolbar. Additional breakpoint functionality is provided by the Simulation Control Window .

Run Simulation.

The current simulation will be executed.

The current simulation will be executed.

Step into Simulation.

The simulation executes a single basic block.

The simulation executes a single basic block.

Break into Simulation.

A running simulation will be stopped (paused).

A running simulation will be stopped (paused).

3.2.2.2 Functions on Simulation Trace Files #

Open Trace File.

Allows for opening of saved INCHRON simulation traces.

Allows for opening of saved INCHRON simulation traces.

Save Trace File as.

A Simulation trace will be saved as

A Simulation trace will be saved as ISF file.

3.2.2.3 Functions for Simulation Visualization #

chronSIM provides a set of diagrams for the visualization of the dynamic system behavior, each offering a view on different aspects of the simulated system. All diagrams can be viewed from the Real-Time Simulator window, which becomes available when starting a simulation or loading a previously saved simulation trace file. The diagrams are available in the Diagrams menu or with the toolbuttons of the diagrams toolbar. Additional diagram functionality for printing or exporting data can be accessed via the windows menu bar or the diagrams context menu. For a detailed description of simulation diagrams see Section 7.7, “Visualization”.

Show Sequence Diagram.

This diagram shows communication activity between tasks

as well as between tasks and ISRs.

This diagram shows communication activity between tasks

as well as between tasks and ISRs.

Show Stack Diagram.

This diagram shows the stack usage of tasks over time.

This diagram shows the stack usage of tasks over time.

Show State Diagram.

This diagram visualizes each task's operating system states

running, ready, waiting or dead over time.

This diagram visualizes each task's operating system states

running, ready, waiting or dead over time.

Show Nesting Diagram.

This diagram shows the nesting depth of functions of a process over time.

This diagram shows the nesting depth of functions of a process over time.

Show Load Diagram.

Shows utilization of microprocessor resources over time.

Shows utilization of microprocessor resources over time.

Create Histogram.

Show a diagram for the statistical distribution of the time interval

of two events (e.g. process start and termination).

Unlike for other diagram types multiple histogram windows may be open at the same time.

The following images show diagram examples.

Show a diagram for the statistical distribution of the time interval

of two events (e.g. process start and termination).

Unlike for other diagram types multiple histogram windows may be open at the same time.

The following images show diagram examples.

Figure 3.3: Sequence Diagram With Three Processes #

Figure 3.4: State Diagram With Three Processes #

3.2.2.4 Usage of the Simulation Control Window #

The Simulation Control window allows the user to define simulation breakpoints. The following breakpoint conditions are possible:

Time based breakpoints (absolute ore relative)

Event based breakpoints (function, process or user defined events)

Break on RTOS violations

Break on violations of defined limits for recursion, function nesting depth as well as stack size.

That way, the compliance with design requirements may be verified immediately during simulation.

Figure 3.5: Simulation Control Window #

3.2.3 Interactive Modeling with chronSYNTH #

The chronSYNTH mode provides interactive modeling features for simulation diagrams. This facilitates model changes from within the simulatior window, which trigger a simulation and an immediate update of simulation diagrams for an immediate update on any effects of model changes. For that purpose, the context menus of simulation diagrams have a sub-menu offering several actions for model modifications. See Chapter 10, Interactive Design of Dynamic Architectures for details. Any changes can be applied by clicking the Run Simulation toolbutton in the Project Window which will restart of the simulation. Once finished the diagrams in the Simulator window will be updated accordingly.

3.2.4 The Validation Mode #

The validation mode requires the chronVAL licensing option and is entered from the project mode window. A detailed description of features of the validation mode is subject to Chapter 8, Validation. For demonstration open the validation example project:

Open the dialog for example project with → and select the project

distributed.iprfrom thechronVAL/distributedfolder.-

Enter validation mode with

→

or alternatively with the shown icon from the toolbar.

Enter validation mode with

→

or alternatively with the shown icon from the toolbar.The chronVAL Response Time Composition and chronVAL Event Spectrum Viewer windows open.

Wait until chronVAL analysis of the project has finished. While not finished the Event Spectrum Viewer will display an Analyzing... message.

Figure 3.6: The chronVAL Validation windows #

3.2.5 The Viewer Mode #

The chronVIEW license option is a restricted mode for using the functionality of INCHRON Tool-Suite simulation diagrams on simulation traces. This includes viewing saved chronSIM traces and the import of custom CSV traces.

In chronVIEW mode INCHRON Tool-Suite will start with a simulation viewer window. The configuration of a chronVIEW license option is described in Section 2.2.2, “License Management”.

The usage of the diagram functions is like described in Section 7.2, “Running a Simulation”.

Opening a simulation trace is done as described in Section 7.8.2, “Loading a Trace-File”.

The import of custom trace files includes the automatic creation of a basic system model which may be opened in the model editor via (chronSIM license option assumed). Management of real-time requirements for imported traces is also available after opening the model editor.

4 Projects #

An inchron project comprises an embedded system's hardware and software model together with additional meta information, specification of real-time behaviour and requirements, generic tool settings and specific settings and configuration for reporting, chronSIM, chronVAL and chronOPT.

An INCHRON project is saved as an IPR file in an XML representation.

This project file contains all task specifications, all source modules including their parameters,

as well as paths to their files.

The Tool-Suite system model editor therefore requires the user to specify a project folder at runtime. By default, the project folder is created in the user's personal folder. With the default setting, the Tool-Suite expects to find all model specifications and associated files in this folder.

If an alternate folder is specified, it will apply to your project file, the project's C source code modules and will be the default search location for any additional model descriptions (e.g. OIL, DBC and FIBEX files).

Name and file identifiers used in simulation models are case-sensitive.

Files with the IPR file name extensions

are associated with the Tool-Suite application

so that ing

will automatically start the Tool-Suite and load the project.

4.1 Project Creation #

After being started the INCHRON Tool-Suite starts up with an empty project.

-

Select the Module System

and there select the project item in the system tree

Select the Module System

and there select the project item in the system treeThe project's global properties and settings are displayed on the right hand side as shown in the screenshot below.

Figure 4.1: Example of Project General Settings #

The project property view contains the following informational items on global project settings:

Project Directory

Project DirectoryThe location of your project's working directory on your file system. By default the project directory is set to the personal folder the user. Since the project related files are stored in the project's working directory it is recommended to use a separate folder for each project. In order to select a working directory the button with the shown icon.

Project name

Enter a unique project name. The project name will be used as basename for the project file.

Author and Email

Version and Last Modified

While the Last Modified field gets updated whenever the project is loaded or saved the Version has to be edited manually.

Project Description

This input is intended for a textual description of your project. You can modify and add information at any time, thus recording your project's progress.

Group Analysis

The Exactness parameter is the number of iterations after which the chronVAL analysis switches to approximation. A higher value for exactness will decrease the pessimism of calculated worst case response times, with the cost of increased analysis computation time.

Group Simulation

If Omit Stack Diagram is checked chronSIM simulation will not record any function stack changes.

if Omit Call Nesting Diagram is checked the chronSIM simulation will additionally suppress the recording of function entry and exit events (including AUTOSAR Runnables).

if Omit Implicit Event Chains is checked the simulation will not record information for tracing the connections of implicit process activation chains and dataflow chains

-

if Global Simulation Replacement override Chains Use this option to globally override the Simulation Replacement of processes and runnables. This does only apply to those processes and runnables with active Simulation Replacement, i.e. not to processes and replacement with assigned entry function.

Log

Log messages from e.g. loading projects, parsing source files and generating simulation

You may save your project settings using

→

or by clicking the

button from the toolbar.

The file extension

button from the toolbar.

The file extension IPR will be appended automatically.

4.2 Modifying the Project Directory #

In some cases you may wish to reorganize your projects on your hard disk, including INCHRON project files and their associated files.

You may use your operating system's tools to move and reorganize your projects in your file system.

The project file of a model contains information about the associated files, including their paths. Files in the project directory or a subfolder will be stored with relative paths. We recommend to also save the project file in the project directory or a subfolder thereof.

After the reorganization of the files associated to your project, the internal integrity of your project files is temporarily inconsistent.

When a project file is loaded into the Tool-Suite after moving in the filesystem, the project's internal file path and file references will be adjusted automatically. The project status will be set to modified and thus has to be saved with Ctrl–S to get a consistent project file.

4.3 Load and Save Projects #

If any of the project's specifications are modified the simulation project file should be saved.

For saving a project use

→ (Ctrl–S)

or click the  icon from the toolbar.

icon from the toolbar.

Alternatively to write to a new project file

in order not to overwrite an existing project file use

→

or click the

icon from the toolbar.

icon from the toolbar.

It is also possible to checkout a project from a subversion repository or to put a project under version control, see Section 12.3, “Version Control for Projects”.

4.4 Global Settings #

In addition to the project directories of your projects and their associated files, some paths to 3rd party tools required for enhanced functionality may be customized.

These additional 3rd party software tools were installed to your computer during the installation of INCHRON Tool-Suite and are used for the output of visualizations of chronSIM's simulation results.

Beside the paths to the additional software tools the length of the recent project list can be adjusted.

The configuration of an editor for source files is not required. chronSIM will use the default application which is associated with the file type.

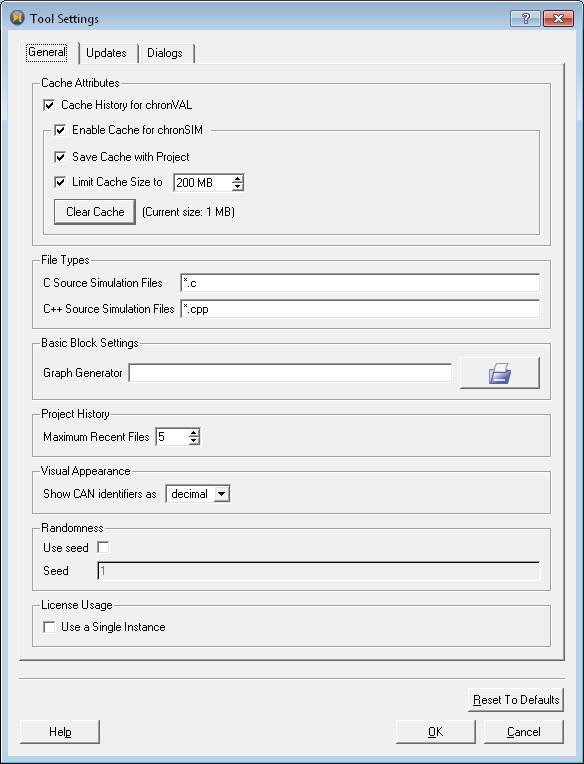

The Tool Settings dialog is available with → . The dialog contains the two tabs General for general settings and Updates for automatically checking for Tool-Suite updates.

4.4.1 General Settings #

Figure 4.2: General Settings Dialog #

4.4.1.1 Caching of Intermediate Files #

In order to speedup source code parsing and the generation of a simulation model the INCHRON Tool-Suite may use a cache of intermediate results on your hard drive.

Objects in the cache are used in favor of re-compilation if the cache object is more recent than the timestamp of the corresponding C source file and included header files. Also, cache data is always specific to a INCHRON Tool-Suite release so that cache data generated with one Tool-Suite release will not be used when running a different release.

The cache behavior may be influenced as follows:

Enable Cache is a global switch to enable the cache. If deactivated its contents will not be deleted automatically.

If option Save Cache with Project is checked, the location of the cache will be in the project working directory (see Section 4.1, “Project Creation”). Otherwise it will be located in the central user directory.

If Cache History for chronVAL is checked the calculation of chronVAL response times will be cached. This speeds up subsequent process state diagram calculation with the tradeoff of increased memory footprint during analysis.

With the currently selected cache location will be cleared. This is useful to cleanup disk space from cache data no longer used.

4.4.1.2 Source Code File Extensions #

Generally the Tool-Suite treats only files of the type .c

as C source code and .cpp as C++ source code.

By changing the field File Types you can adapt

the Tool-Suite to accept other file types in your projects.

Enter the file types as *.c as shown in Figure 4.2, “General Settings Dialog” . Multiple file types have to be separated by a semicolon (;).

The file types entered here can also be used as filters in the file dialogs when adding files to your project. They are stored permanently, too.

4.4.1.3 Basic Block Graph Viewer #

In order to view graphs resulting from the basic block analysis of the model's source code the external program dot.exe from the ATT GraphViz package is used. The directory path of the program is usually configured during Tool-Suite installation and does not need to be changed.

4.4.1.4 Project History Length #

Maximum Recent Files set the max. number of entries of the → menu.

4.4.1.5 Format of CAN Identifiers #

Packages of CAN messages have a numeric ID which is shown by some components of the INCHRON Tool-Suite. With Show CAN Identifiers as the base of numerical presentation may be changed for your convenience.

4.4.1.6 Initialization of Random Number Generators #

During simulation pseudo random numbers are applied in two cases:

Stimuli generators may be subject to random variation, and

the functions of the task model may explicitly call random generators.

In general random generators of stimuli generators are initialized with a pseudo random seed which results in a new pseudo random stimulation sequence for each simulation run. By checking Use seed random stimulation sequence will be reproducible with a given Seed value (see Figure 4.2, “General Settings Dialog”). The Seed value will be interpreted as a 64bit integer with each bit being evaluated to initialize the random number generator.

An activated seed also applies to the random generators and functions called in the model source code.

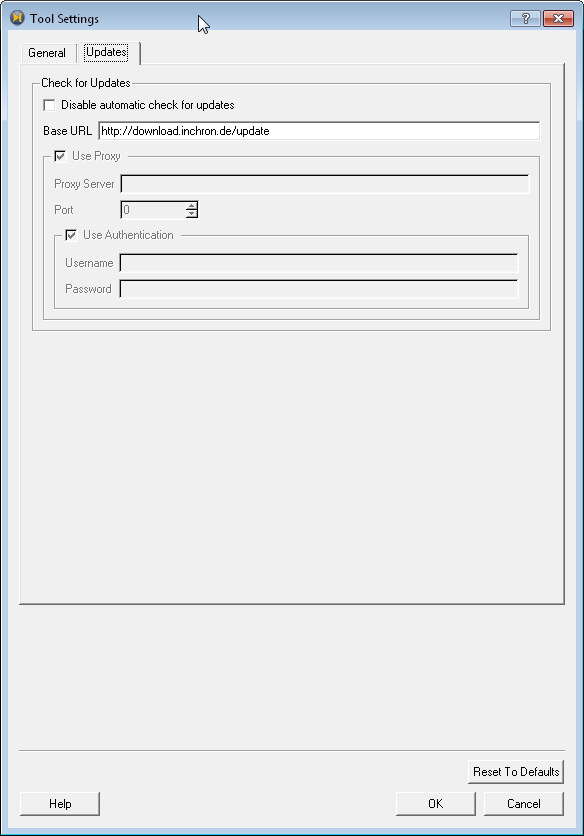

4.4.2 Update Settings #

4.4.2.1 Automatic Update Checking #

INCHRON Tool-Suite may check automatically for release updates. This check may also be done manually from the menu.

For configuration of the automatic update check select the Updates tab of the Tool Settings dialog.

Figure 4.3: Tool-Suite Update Settings #

For checking available updates the INCHRON Tool-Suite will send its release number, build date and the number of the support contract to the INCHRON update server. In case an update is available the information of the update server's response will be shown in the Update Status dialog. It contains the number of the latest available release and the latest build date of the release currently in use.

Automatic update checking may be suppressed by checking Disable automatic check for updates.

The Base URL option allows to set an intranet server instead of the INCHRON update server in order to restrict update to releases approved by your responsible department. Please contact your sales partner for details.

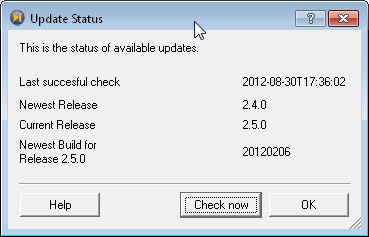

A manual update check is triggered with → which will show the Update Status dialog shown below.

Figure 4.4: Tool-Suite Update Status #

ing Check Now will trigger an update check which will provide the following information items:

Last successful check shows the time of the last successful update check.

Newest Release is the release number of the latest available INCHRON Tool-Suite release.

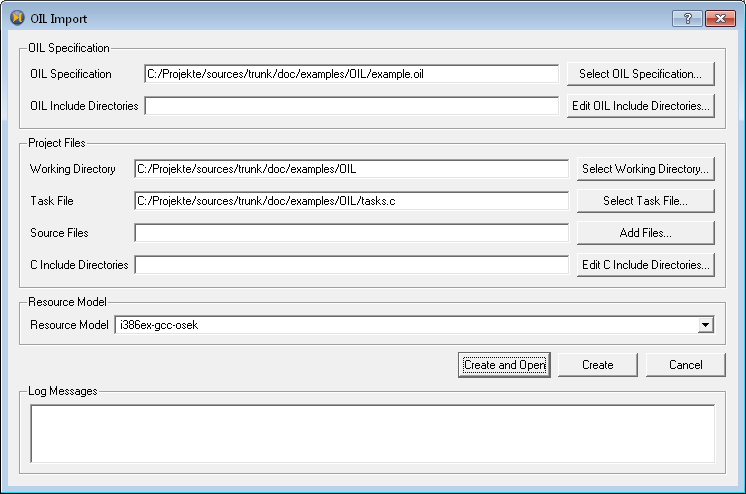

Current Release is the release number of the currently running INCHRON Tool-Suite.