EDAG–INCHRON Partnership:

Known Latency Is The Future Currency.

INCHRON Teams Up with EDAG for in-depth software timing analysis in SDVs

Collaboration between EDAG and INCHRON is allowing the automotive industry to effectively manage software timing and latency in the new E/E architectures used in SDVs.

Summary

Your Advantage

- Early Risk Mitigation

- Optimized Performance

- Integrated Toolchain & Model Reuse

- Lifecycle Continuity and Digital Twin

- Process Efficiency and Team Alignment

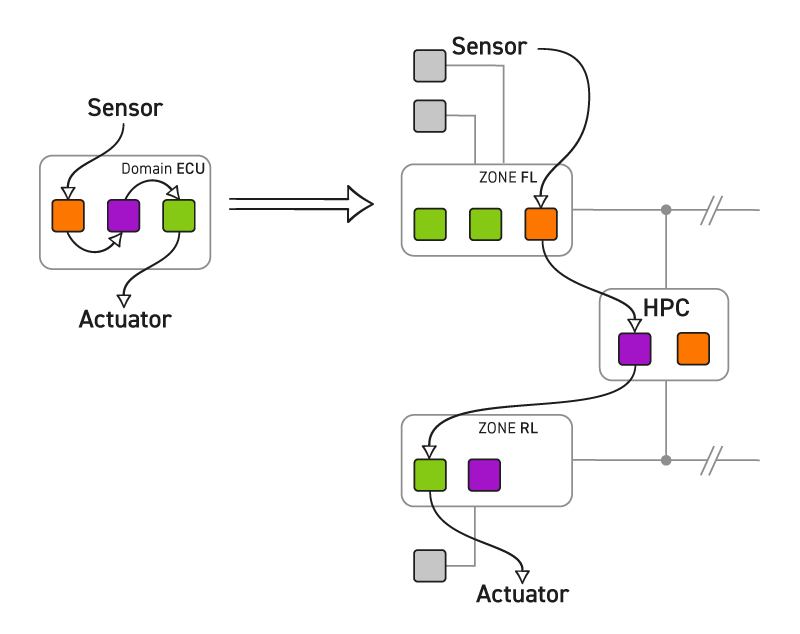

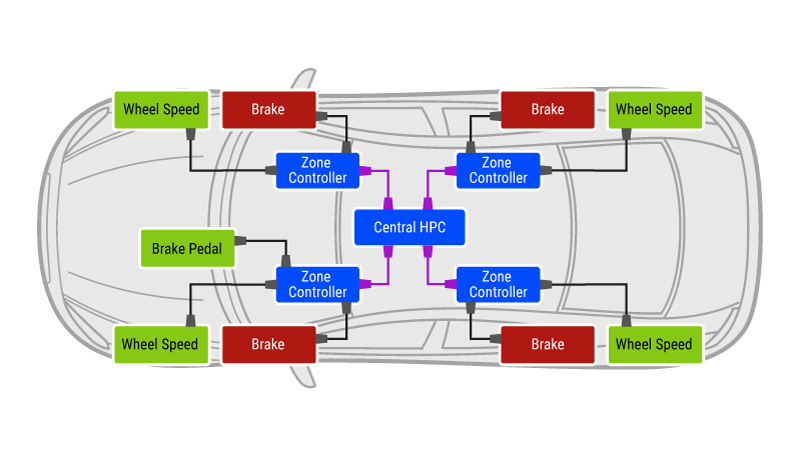

Modern vehicles are increasingly being defined by their software, from the day they roll off the production line to updates throughout their operational lives. With complex software functions now spread across the vehicle in zonal architectures, automotive development teams must keep a closer eye on timing and the end-to-end latencies that result.

EDAG and INCHRON are collaborating to ensure that model-based approaches persist beyond the development process, providing a “digital timing twin” that supports the rollout of over-the-air software updates.

Introduction

EDAG (a leading vehicle engineering firm) and INCHRON (a real-time systems simulation specialist) have partnered to address the challenges of Software-Defined Vehicle (SDV) development. This collaboration focuses on ensuring that modern automotive E/E architectures meet strict real-time constraints (like end-to-end response times) from the earliest design stages through to vehicle operation. By combining EDAG’s expertise in model-based E/E architecture design with INCHRON’s event-chain timing analysis tools, the partnership provides a comprehensive methodology to manage latencies and timing requirements throughout the development lifecycle. The core idea is to maintain a consistent, closed loop from requirements engineering to system release, so that latency and performance requirements are not just afterthoughts but are built into the architecture from day one. This ensures that safety-critical timing (for features like brake-by-wire or ADAS) and customer experience metrics (like user interface responsiveness) are met by design, rather than tackled late in prototyping or production.

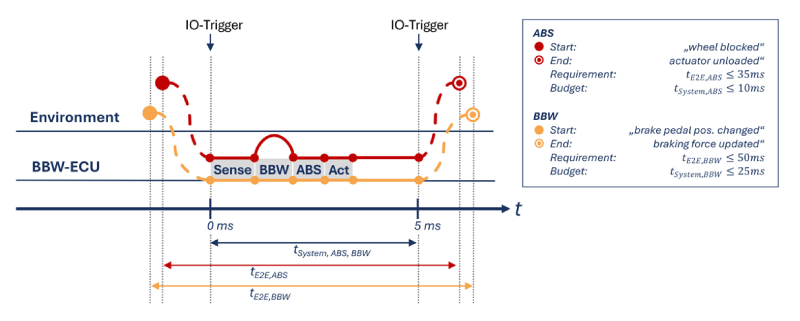

At the heart of the partnership’s approach is an event-chain-centric methodology. EDAG’s architecture modeling process defines each vehicle function (feature) and its static behavior as an event chain (German: Wirkkette) – a sequence of causally linked events from stimulus to response. INCHRON’s complementary method builds a logical event-chain model for each feature, independent of any specific hardware, capturing the cause-and-effect flow of the intended behavior. Crucially, end-to-end (E2E) latency requirements (stemming from legal standards, safety needs, or user experience targets) are embedded in these logical event chains from the start. This provides “track limits” – explicit timing budgets for each chain – against which the design is continuously validated.

The methodology has significant technical depth, allowing engineers to allocate timing budgets to each link in an event chain within the overall E2E deadline. This yields a timing-aware architecture blueprint where every function has defined latency targets and subdivisions. Early in development, the team conducts event-chain analyses and simulates expected latencies even before specific ECU hardware or software tasks are decided. The insights gained at this concept stage directly inform the architecture design, ensuring it is correct-by-design for timing. As development progresses, the logical event chains evolve into technical event chains (concrete implementations on ECUs or HPCs), but the timing requirements remain traceable and testable throughout. Real-time performance is continually analyzed in the context of the system’s causal flows, allowing design decisions to be evaluated for their impact on latency and scheduling. This rigorous methodology means potential timing bottlenecks or deadline violations are detected and resolved before they can cause late-stage issues. Overall, the event-chain-driven development approach gives decision-makers confidence that real-time constraints are systematically managed rather than left to chance.

A key enabler of this methodology is the integration of tooling. The partnership connects PREEvision (a model-based E/E architecture design tool) with INCHRON’s chronSIM (a scheduling and timing simulation tool) in a closed-loop workflow. Through a jointly developed interface, architects can exchange event-chain models and timing data bidirectionally between PREEvision and chronSIM. In practice, this means the architectural model (ECUs, networks, software components, etc.), along with its event chains and timing budgets, is exported to chronSIM for simulation of real-time behavior. chronSIM then evaluates scheduling, bus traffic, and processing delays to predict latencies and identify any constraint violations. The results (e.g., detailed latency measurements for each event chain) are fed back into PREEvision automatically. This tight integration allows for iterative refinement. Engineers can adjust the architecture in PREEvision (for example, reassign tasks, change scheduling parameters, or alter network layouts) in response to simulation findings, and then re-simulate to validate the improvement.

The toolchain integration is designed for continuous use across the development cycle. For instance, the partnership advocates using chronSIM in a CI (Continuous Integration) pipeline for automated timing regression tests. Every time the architecture model changes or software is updated, a new timing simulation can run to ensure no regressions in E2E latency. Because the event chains and timing requirements in the model correspond to real observable events in the eventual system, the same model can be used to verify timing on physical prototypes and vehicles. Importantly, the integration supports not just forward simulation but also feedback from the field: timing traces or measurements from real test drives can be imported back into the model to refine simulation accuracy. This closes the loop between virtual design and real-world data, enhancing the model’s fidelity over time. Overall, the PREEvision–chronSIM toolchain integration bridges the gap between high-level architecture design and low-level timing behavior, ensuring that the model-based design and analysis stay in sync at all times.

Lifecycle Integration: From Concept to After-Sales

The EDAG–INCHRON partnership explicitly addresses the entire vehicle lifecycle – from early concept through series development and even after the vehicle is on the road. This end-to-end perspective ensures that timing and performance remain under control as the product matures and evolves:

- Concept Phase (Upfront Architecture Design): In the early concept stage, the focus is on “shift-left” validation – modeling timing requirements in PREEvision and performing latency simulations before any implementation is undertaken. Engineers create an abstract SDV architecture with features and event chains, setting E2E latency targets for each chain. Using Model-Based Latency Simulation (MBLS), architects verify that each feature’s event chain can meet its timing budget under various scenarios. Early histograms of simulated latencies highlight which system paths are likely to be problematic, so the team can proactively optimize those paths. By catching timing issues in the concept phase, the partnership’s approach avoids costly redesigns later and establishes a “correct-by-design” foundation. The model-based systems engineering (MBSE) approach also yields a consistent event-chain database that can be maintained and reused as the project moves forward.

- Series Development (Integration & Optimization): During the detailed development and integration phase, the event-chain model grows in fidelity as concrete software tasks (runnables), network communications, and ECU configurations are added. Here, the emphasis is on finding the optimal configuration within the design’s “track limits” (the timing requirements defined in concept). For example, if thousands of software runnables must be allocated across a few central high-performance computers (HPCs), the integrated toolchain can simulate different scheduling and partitioning strategies. Engineers perform what-if analyses in chronSIM to evaluate design alternatives, such as how deploying a set of functions on one processor versus another affects overall latency. The event-chain perspective provides a framework to measure end-to-end effects of these choices, distinguishing “good” vs. “bad” latency outcomes across the entire vehicle. This data-driven approach guides architects and integrators to iterate toward a design that meets all real-time requirements with minimal performance bottlenecks. Crucially, any design changes found effective in simulation can be fed back into the PREEvision model and implemented in the actual E/E architecture. Throughout series development, the partnership’s methodology promotes cross-team alignment, with architecture teams, function owners, and software integrators all working from the same timing model and KPIs (e.g., worst-case latencies, data age, synchronization metrics). This bridges traditional gaps between system design and implementation, even empowering “software-first” developers to understand and adhere to the timing requirements relevant to their code. The result is an optimized system design – a kind of “best possible racing line” within the given track limits – achieved long before physical prototypes or hardware tests, thereby saving time and ensuring reliability at launch.

- After-Sales (Operation and Updates): The partnership’s vision extends into the post-production phase, addressing how to maintain performance when the vehicle is in the field. As OEMs move toward continuous improvement and over-the-air (OTA) software updates, the challenge is to guarantee that new features or updates won’t violate real-time constraints in any vehicle variant or usage scenario. EDAG and INCHRON propose using a “digital timing twin” – a living model that augments the MBSE architecture and event-chain simulation with live vehicle data. In practice, the timing twin means that data from the vehicle fleet (e.g., timing traces from ECUs in customer cars or test vehicles) can be fed into the chronSIM model to keep it calibrated. Before deploying a software update or adding a new cloud service, engineers can run a virtual validation on this digital twin, testing the new software in a simulation that reflects real-world conditions and worst-case scenarios. This allows the team to see, for example, if an added ADAS feature might introduce an unacceptable delay in a braking sequence under heavy network load, all before the update is rolled out to actual cars. By catching such issues virtually, the partnership’s approach cuts down on validation costs and prevents trial-and-error in the field. It also ensures a consistent customer experience over the vehicle’s lifetime. Even as functionalities change, the vehicle will continue to meet its defined timing and performance targets. In short, the EDAG–INCHRON digital timing twin concept enables OEMs to “stretch-right” the quality assurance, continually optimizing and verifying vehicle performance throughout its operational life.

For decision-makers, such as heads of E/E architecture, CTOs, and platform managers, this partnership offers tangible benefits grounded in technology:

- Early Risk Mitigation: By front-loading latency analysis into the concept phase, the approach catches timing issues when they are fastest and cheapest to fix. This early validation avoids late-stage surprises and costly redesigns, keeping development timelines on track.

- Optimized Performance by Design: The event-chain-centric method ensures that real-time performance is engineered deliberately, not left to chance. Design decisions, such as ECU consolidation, scheduling policies, or network selections, can be evaluated quantitatively for their impact on end-to-end latency. The result is an architecture tuned for best performance within given constraints, which translates to reliable and responsive features for end users.

- Integrated Toolchain & Model Reuse: The seamless integration of PREEvision with chronSIM means architecture models and timing simulations stay in sync. Engineers can reuse the same model and data throughout the project, from design to testing, reducing duplicate work and human error. This continuity, along with a consistent event-chain database, accelerates development and improves quality through model reuse and knowledge transfer to future vehicle projects.

- Lifecycle Continuity and Digital Twin: The methodology creates a single source of truth for timing requirements that carries through to after-sales. The digital timing twin concept allows manufacturers to continuously monitor and optimize vehicle E/E performance using real data, enabling safe deployment of updates and new services. This reduces in-field issues and validation costs by shifting testing into the virtual domain, all while guaranteeing a consistent user experience over the vehicle’s lifetime.

- Process Efficiency and Team Alignment: Adopting this event-chain-driven development process can streamline E/E development workflows (development process optimization). It encourages better collaboration between system architects, software developers, and suppliers by providing clear, formalized timing targets for each stakeholder. Everyone works toward the same performance goals, supported by concrete simulation data and timing KPIs, which improves transparency and trust in the design. Ultimately, this leads to higher-quality outcomes (fewer late bug-fixes) and can reduce both development time and costs through fewer iterations.

By addressing the new complexities of SDV architectures with a rigorous, tool-supported approach, the EDAG–INCHRON partnership helps OEMs and Tier-1 suppliers de-risk their E/E systems and build the next generation of vehicles with confidence in their real-time behavior.