Virtual Verification of Timing Requirements Shortens Development Cycles

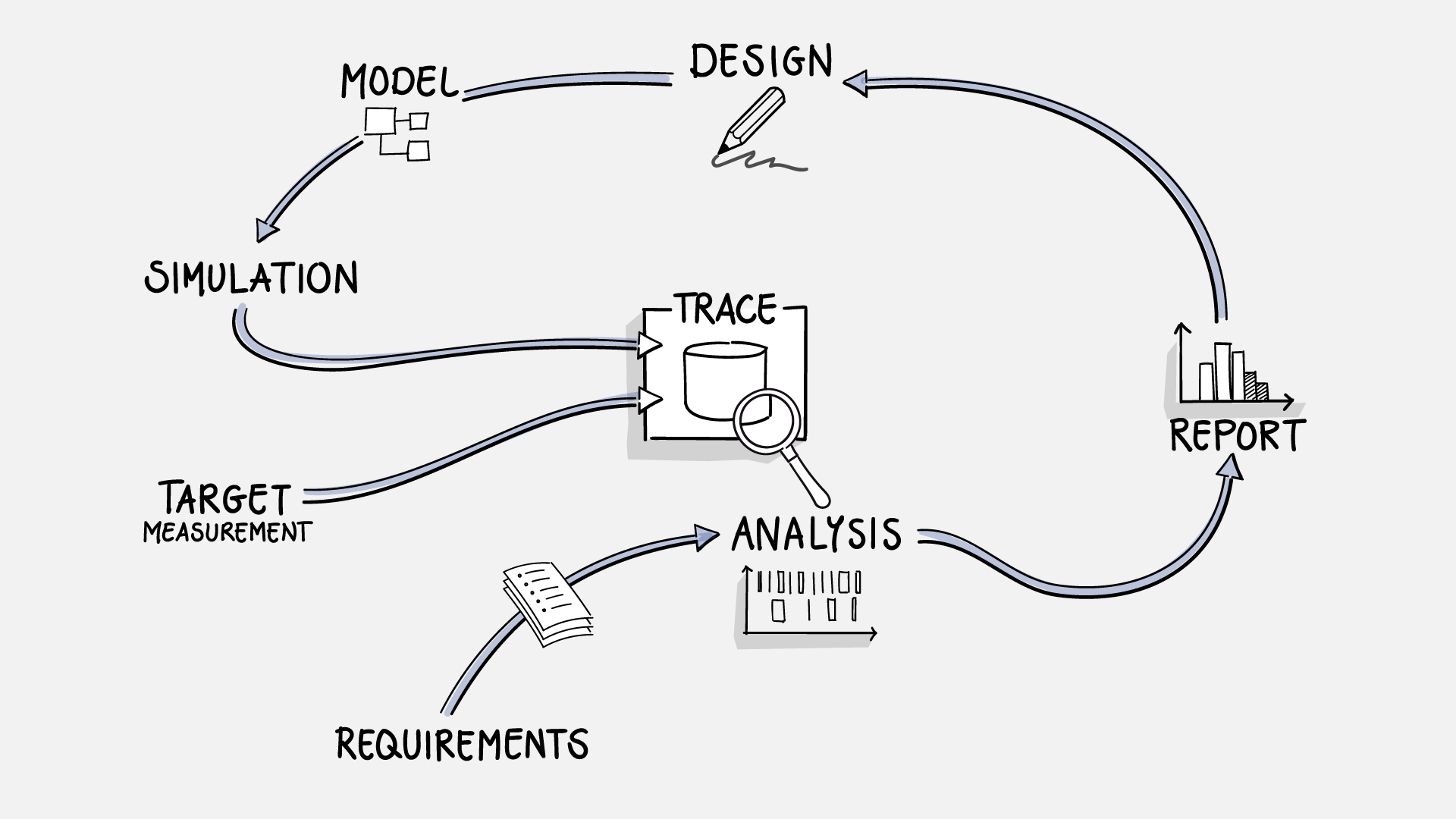

As the complexity of features continues to increase over the lifetime of a project, the consumption of available resources in the target hardware also increases. Verifying that performance requirements remain fulfilled only at HIL (Hardware-in-The-Loop) integration not only ties up valuable test resources but, due to its operational complexity, frequently stalls an agile workflow that is striving for shorter development cycles. For this reason, the industry is currently moving towards a model-based approach with real-time simulators evaluating increasing numbers of real-time requirements even without having to turn to real target hardware.

The INCHRON chronSUITE incorporates everything needed for virtual verification of timing requirements at model level, be it a simple manual process or as part of a unified continuous integration scenario. Test results, findings, and even optimizations and resolutions require just a matter of minutes to hours to implement, not days. Hidden pitfalls are discovered at early stages of the design process, development cycles speed up and project delays are diminished

Free 30 Minutes Telephone Consultation

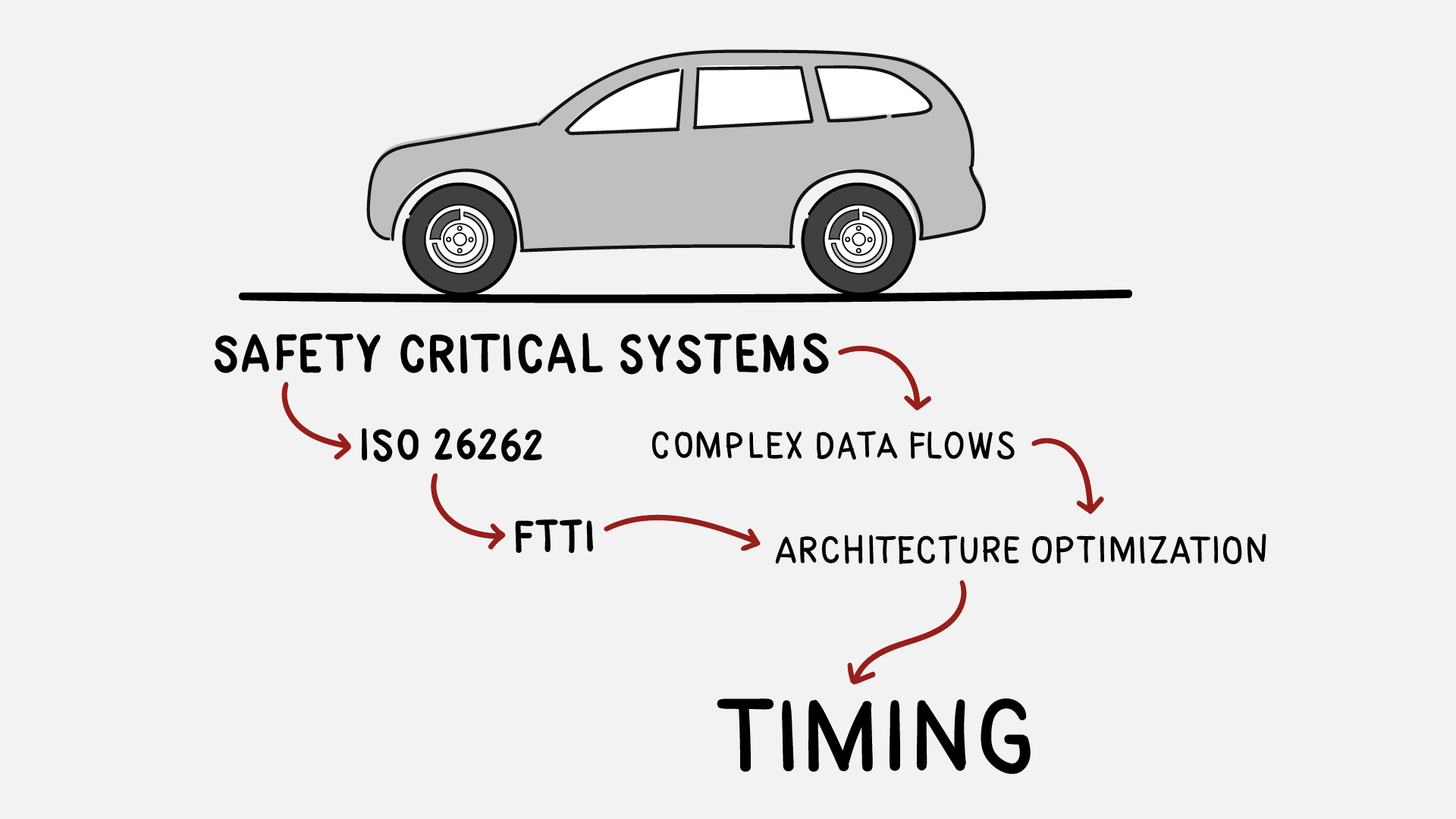

Model-Based Simulation of Safety-Critical Automotive Control Systems

Verification of Timing and Performance Requirements

Trace data obtained by virtual prototyping and simulation or by measurements on the target hardware is uploaded to a dedicated test system running the actual trace analysis solution. Here data from multiple ECU sources is merged, synchronized and afterwards verified against the set of timing and performance requirements. Eventually, an evaluation report is generated, and notifications to interested stakeholders are sent out.