Cost-Effective Alternative to HIL

If there is one thing engineering teams would like more of, it is HIL resources. This tangible, but expensive, resource has earned an almost divine status as the only platform upon which failures can be tested and resolved.

However, with many failures being traced back to hard-to-find timing issues, and system complexity increasing exponentially, alternative approaches are needed. This has been highlighted further as employees relocate to home-offices and HIL access becomes impossible.

Model-based simulation, using clearly defined timing requirements, allows sporadic failures to be determined more quickly. This is possible thanks to rapid iteration cycles replacing repeated project builds to test potential solutions. It also allows remote teams to collaborate, share, and cooperate more easily than ever before.

Making the Case for Virtual Verification

Slipping deadlines are a sad reality of modern automotive programs as embedded control units (ECU) and domain controllers increase in complexity. Delays during the integration process are, sadly, a fact of life as teams attempt to determine how to resolve a host of issues.

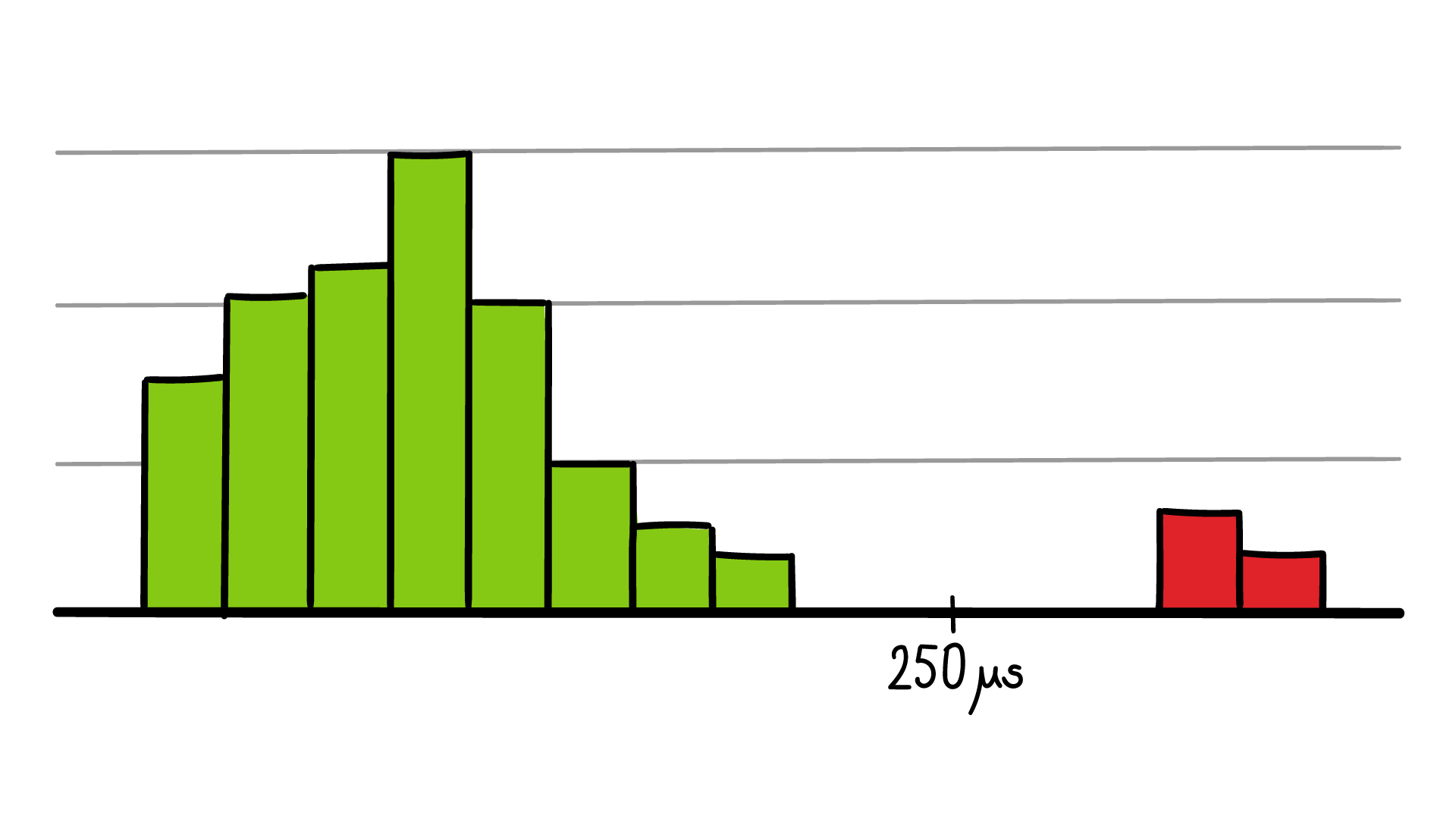

The most challenging issues to resolve are those that appear sporadically. Without a clear cause and effect, many hours of time can be lost just diagnosing under which conditions the issue can be reproduced. Teams rely on hardware-in-the-loop (HIL) systems due to their capability but, being complex and costly platforms, they often have limited availability.

An Alternative to the HIL

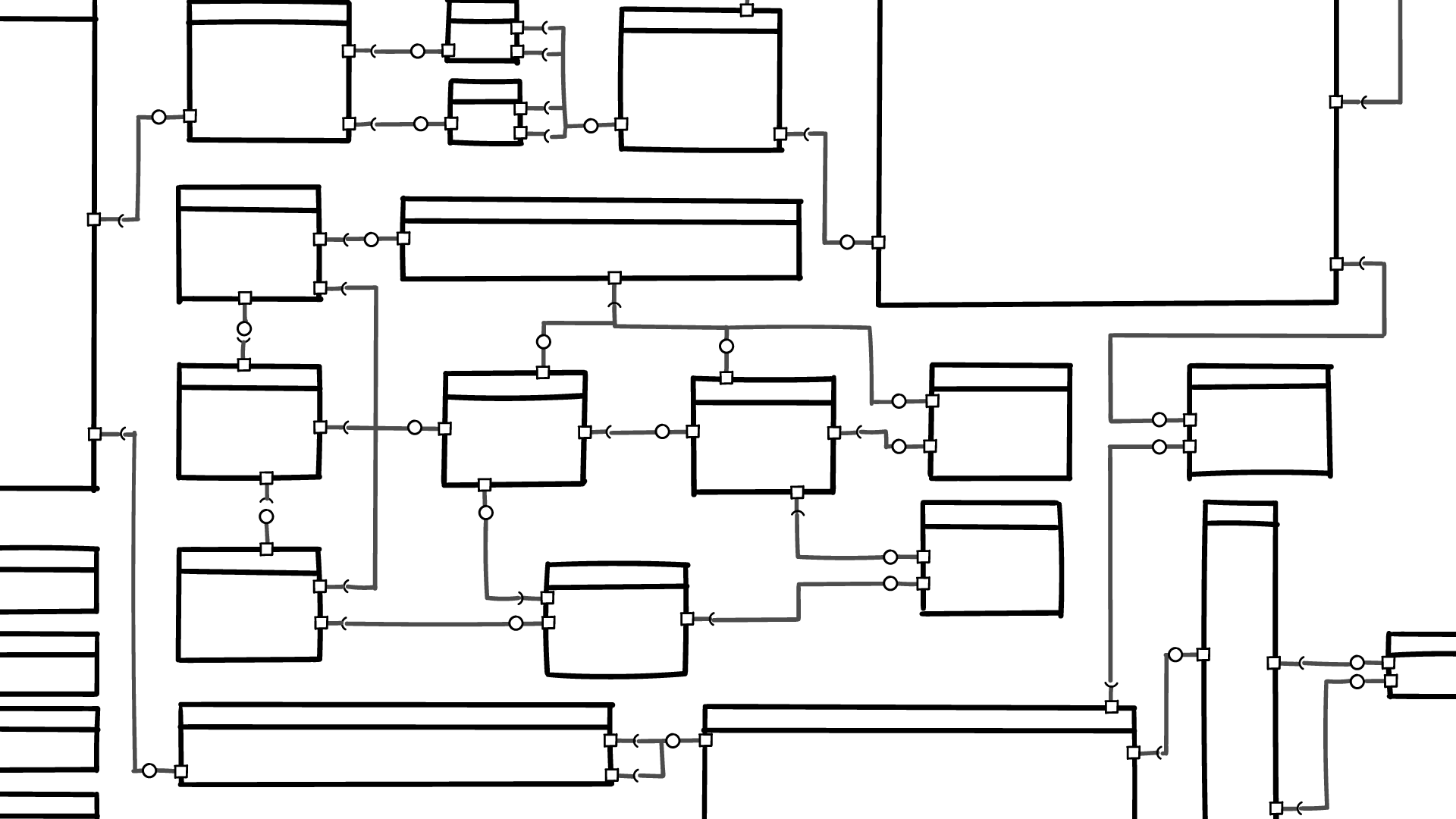

Model-based verification through system simulation provides a reliable, faster, and more cost-effective alternative to working exclusively with a HIL. Additionally, stress tests and in-depth analysis can be easily undertaken to check out the system’s robustness. Many ECUs are already modelled during the development phase of a project using tools such as chronSIM from INCHRON. These models can be reused and updated at any point during the development process.

Virtual verification also allows the impact of new features to be quickly evaluated before implementation in hardware. Using timing budgets, either based upon developer experience or determined from previous HIL runs, any detrimental effect can be analyzed and resolved early. As a result, sporadic errors can be found several weeks, or even months, earlier.

Rapidly Simulate Potential Solutions

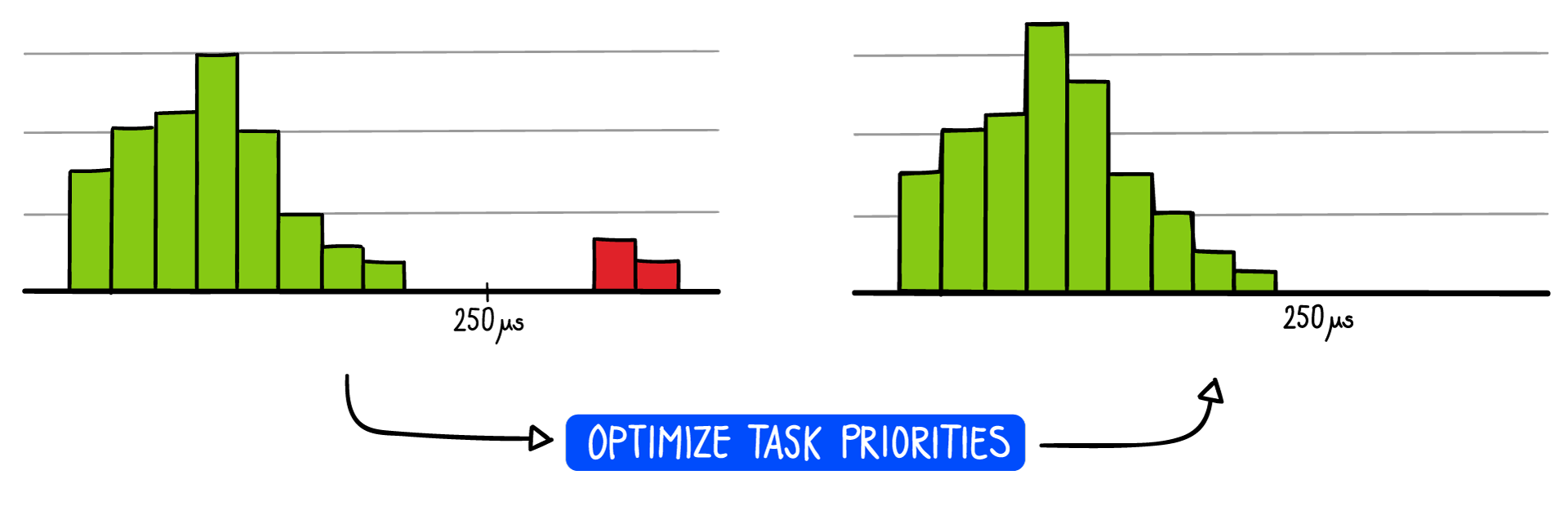

Once the issue has been determined, possible resolutions can be trialed immediately. Tasks priorities and core assignments can be changed, none of which require going through the process of rebuilding the code. This not only rapidly resolves the issue at hand, it also ensures that new issues are not being created.

The INCHRON Tool-Suite is ideal for remote teams collaborating together on complex software applications and resolving challenging timing issues. If your organization faces such timing problems during software integration, why not get in touch with our team to discover how we can help?