INCHRON is an active member of the AUTOSAR consortium and has a strong footprint and proven track record of success in the automotive industry.

Is Timing On Your Radar? Take the Test!

Defining clear timing requirements alongside functional requirements has delivered proven advantages to automotive software development teams. But responsibility for timing goes beyond the system architect – it needs to live across the entire development process.

Participate in our Timing Checklist Assessment to learn how well timing is considered by your development team, and discover what could be improved.

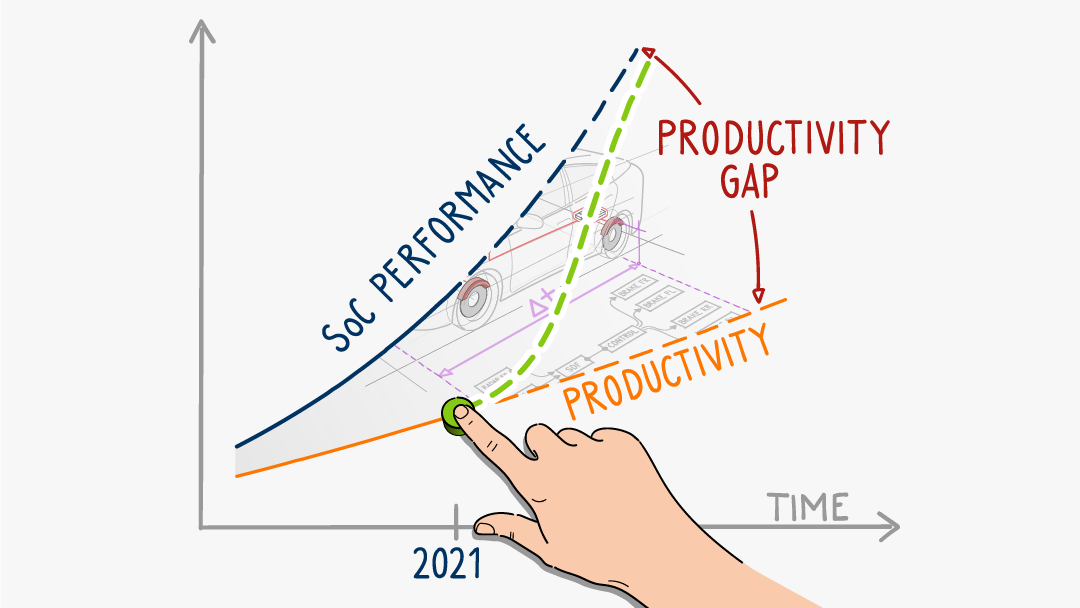

Tackling the HPC Design Productivity Gap

As the number of transistors per die grew, following Moore’s Law, engineers struggled to design and verify their chips using the available EDA tools. The difference between what was attainable using the latest technology, and what could feasibly be implemented, was termed the Design Productivity Gap.

Today’s HPCs and cross-domain controllers in automotive face a similar challenge. While recent SoCs are not short on performance, the projects they are being used in suffer from delays due to problems caused by the real-time demands of the application. This article explains how they are being tackled.

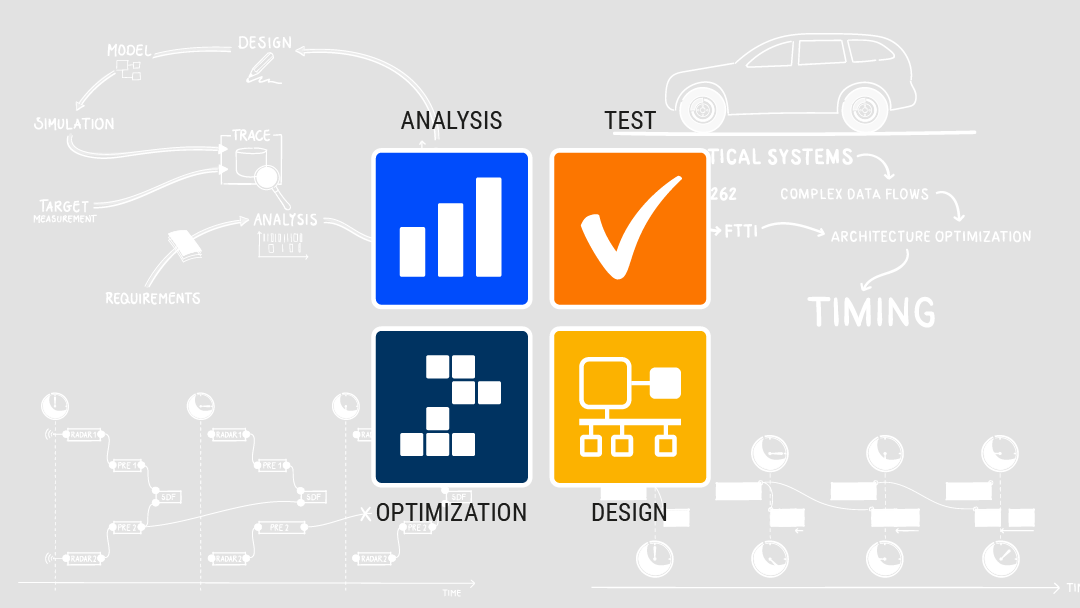

Keep an Eye On Timing, From Design Through to Test

Discover how our customers use our leading timing optimization toolkit in their projects. The design stage is critical to ensure timing issues are eliminated from day one of your projects, keeping clock drift and synchronicity in check. Because root cause analysis accounts for 80% of the time needed to fix an error, comprehensive analysis is a fundamental prerequisite to understand real-time system behavior. Brute force is no longer a valid approach to optimization. Instead, your engineers can efficiently explore the design space with a model-based approach. Finally, during test, our methodology supports virtual verification within a continuous integration workflow.

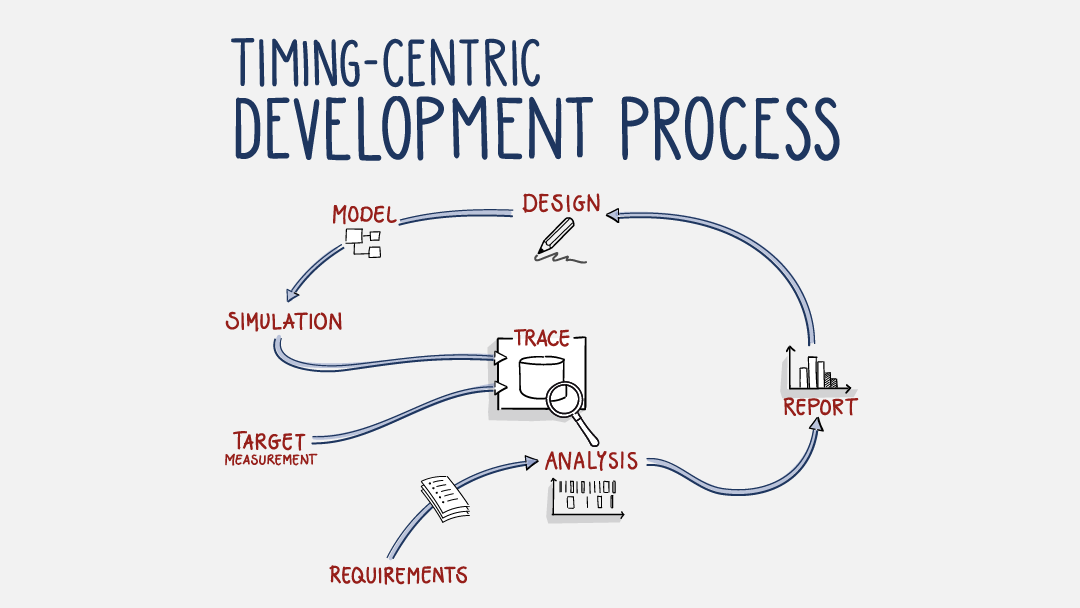

Put Timing at the Center of the Development Process

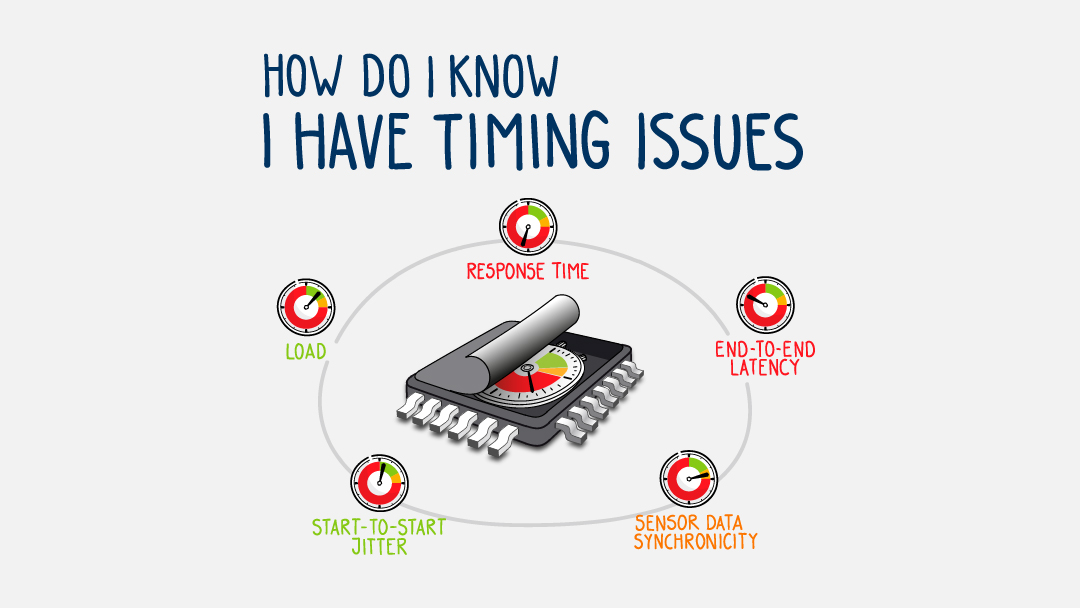

Would you prefer to find timing issues yourself, or have them find you?

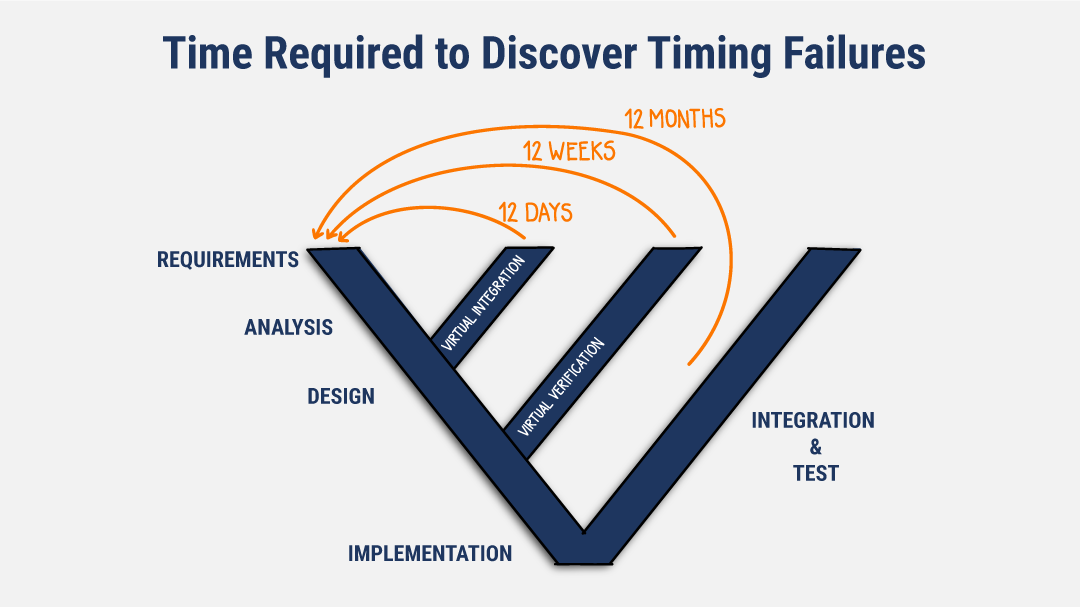

By placing timing at the center of your software development process, you and your team can learn the causes of timing issues before they happen, instead of discovering them during integration or later disguised as functional problems.

The Tell-Tale Signs of Timing Related Issues

Timing problems are not found; they find you. While such issues appear to be random, they can always be linked to a specific cause. Learn some of the technical indicators for timing issues, and the signs indicating a lack of consideration for timing in the development process, in this article.

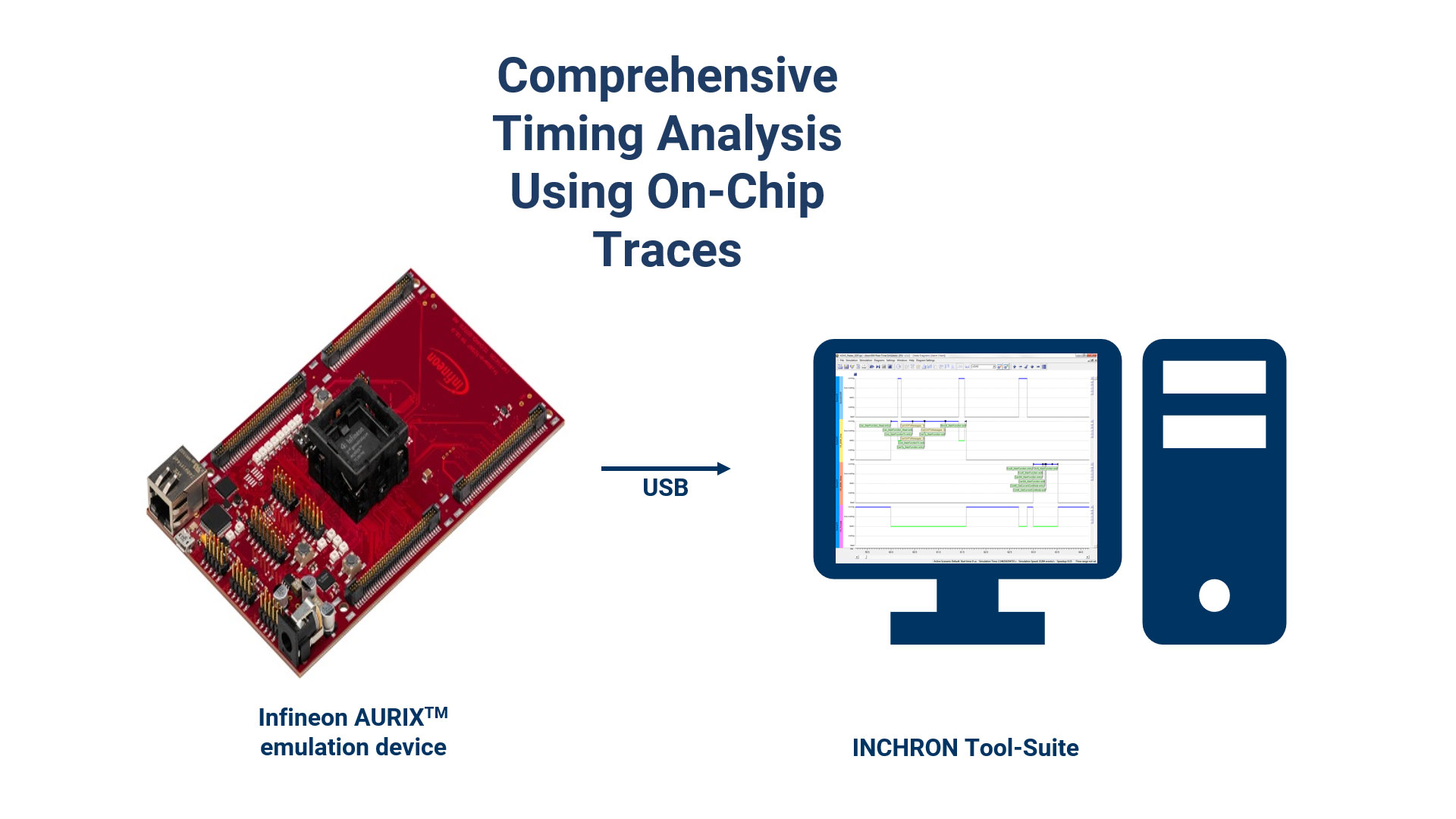

Intrusive vs. Non-Intrusive Tracing

Trace information serves as the basis for analyzing the root causes of a wide variety of problems that are revealed by system tests on the target hardware. When it comes to the mechanism of trace generation and recording, there are basically two approaches with their respective pros and cons: intrusive tracing and non-intrusive tracing.

Read more about the pros and cons of both tracing methods in the context of embedded real-time systems, and how you can benefit from non-intrusive on-chip tracing for comprehensive timing analysis on the Infineon AURIX platform.

Auto-Testing Timing in Your CI/CD Pipeline

Many teams use continous build / continous deployment (CI/CD) pipeline in their development workflow. Timing requirements can automatically be checked in the test pipeline. chronVIEW is easily integrated using a Docker container.

Development of Safety-Critical Systems: The Timing Aspect

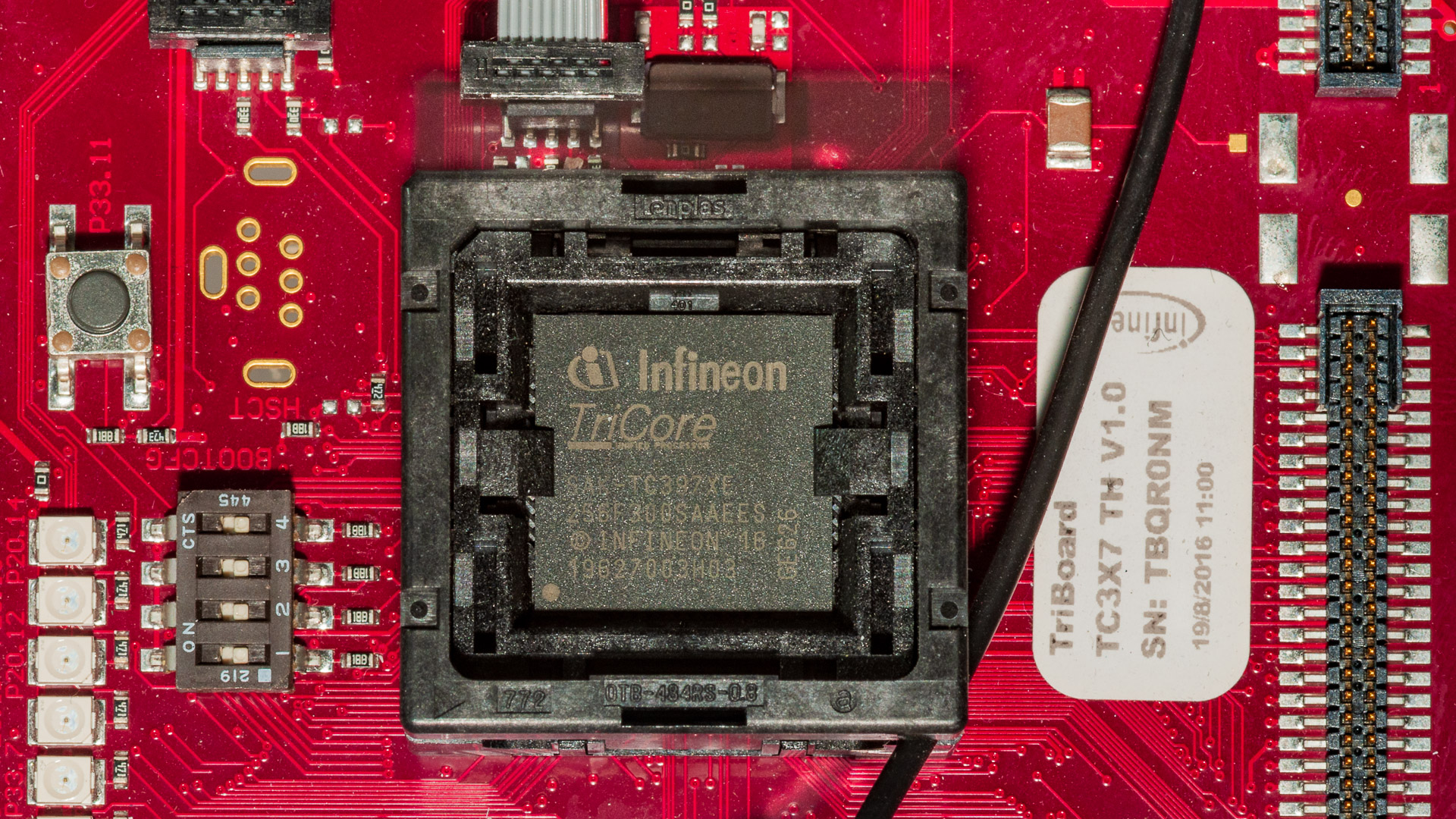

Timing issues that remain undetected or unresolved in a safety-critical system compromise safety – to an extent and in a way that is rarely predictable. Learn how to master the complexity of the timing aspect and how to perform a comprehensive timing analysis by using the INCHRON chronSUITE and the Infineon AURIX MCDS on-chip trace feature.

Infineon AURIX: Unlocking the Potential of Multi-Core Timing Analysis

Infineon’s Multi-Core Debug Solution (MCDS) provides non-intrusive, parallel trace output that is a very powerful tool to analyze and debug AURIX(TM)-based real-time systems in full operation. Learn how to maximize its benefit for comprehensive timing analysis.

End-to-End Performance Optimization for Autonomous Driving

High quality and safety-critical requirements, aggressive time to market schedule, and increasing technical and organizational complexity are fundamental constraints for autonomous driving. Using the most proven development methods and tools is the key to success. But which aspects are crucial?

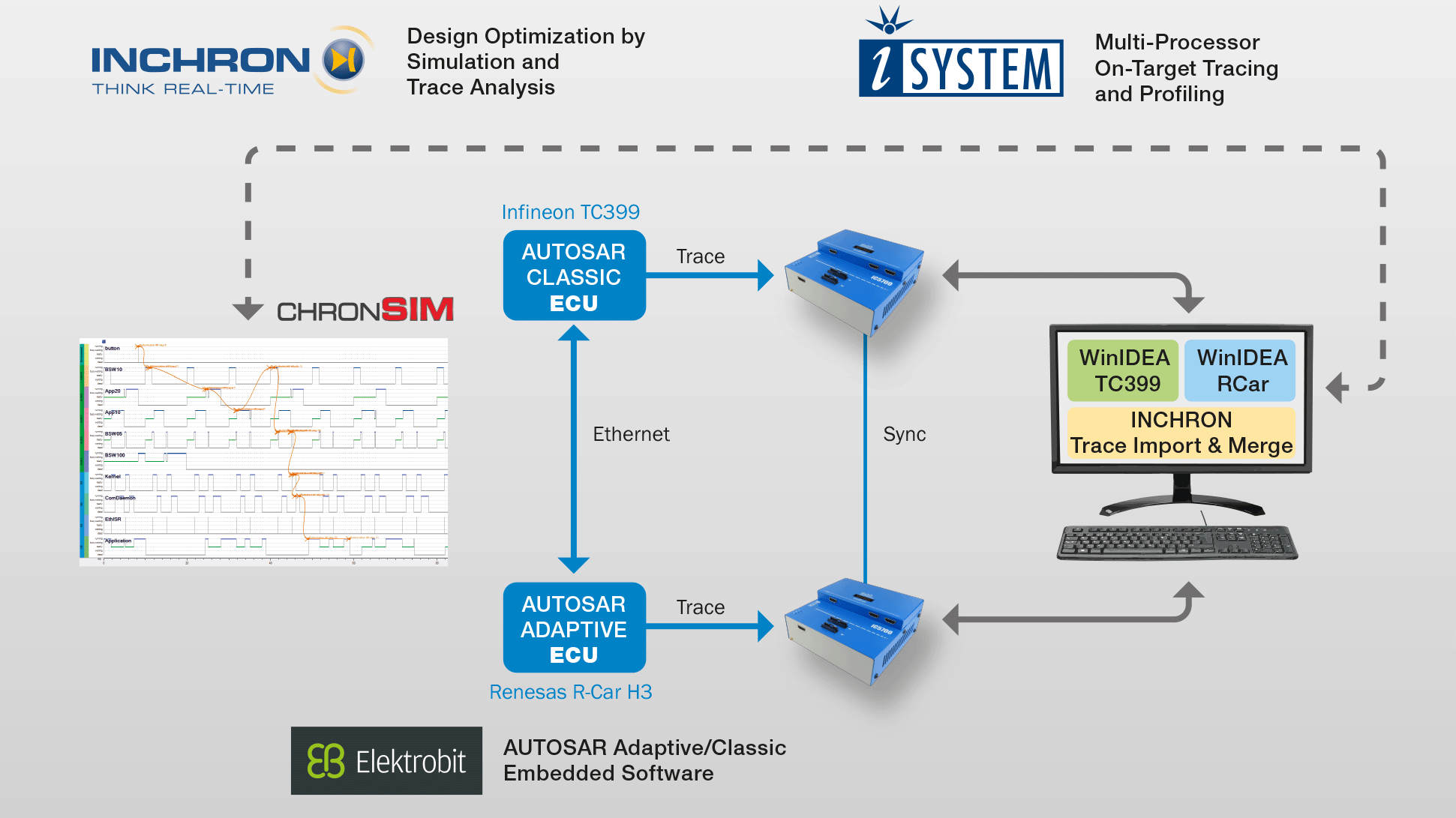

Event Chains in Mixed AUTOSAR Classic and Adaptive Platforms

Systems comprising devices based on AUTOSAR classic and adaptive platforms will soon be present in every major vehicle. End-to-end timing along the event chains will be a critical key design element.

Elektrobit, iSYSTEM and INCHRON have created an integrated solution (including demo) for design, software development and tracing.

Perfection in Real-Time: A Key Enabler for Autonomous Driving

Autonomous driving is the most disruptive innovation in the automotive sector ever. It is going to fundamentally change the way we travel by car. Major technological challenges, however, have yet to be overcome to enable fully autonomous driving.

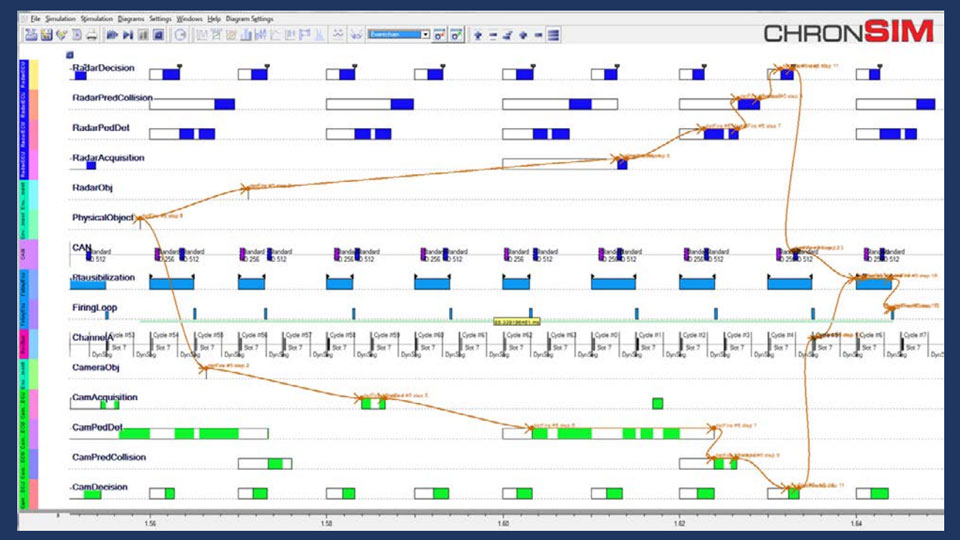

Simulation of Safety-Critical Automotive Control Systems

Electronic control units (ECUs) for safety-critical systems have been successfully developed for decades. In recent years, ADAS and autonomous driving have resulted in an increasing number of software components and microprocessor cores in such systems.

But what does a methodology look like, that considers different aspects of timing in complex safety-critical systems in an efficient, practical and well-proven way?

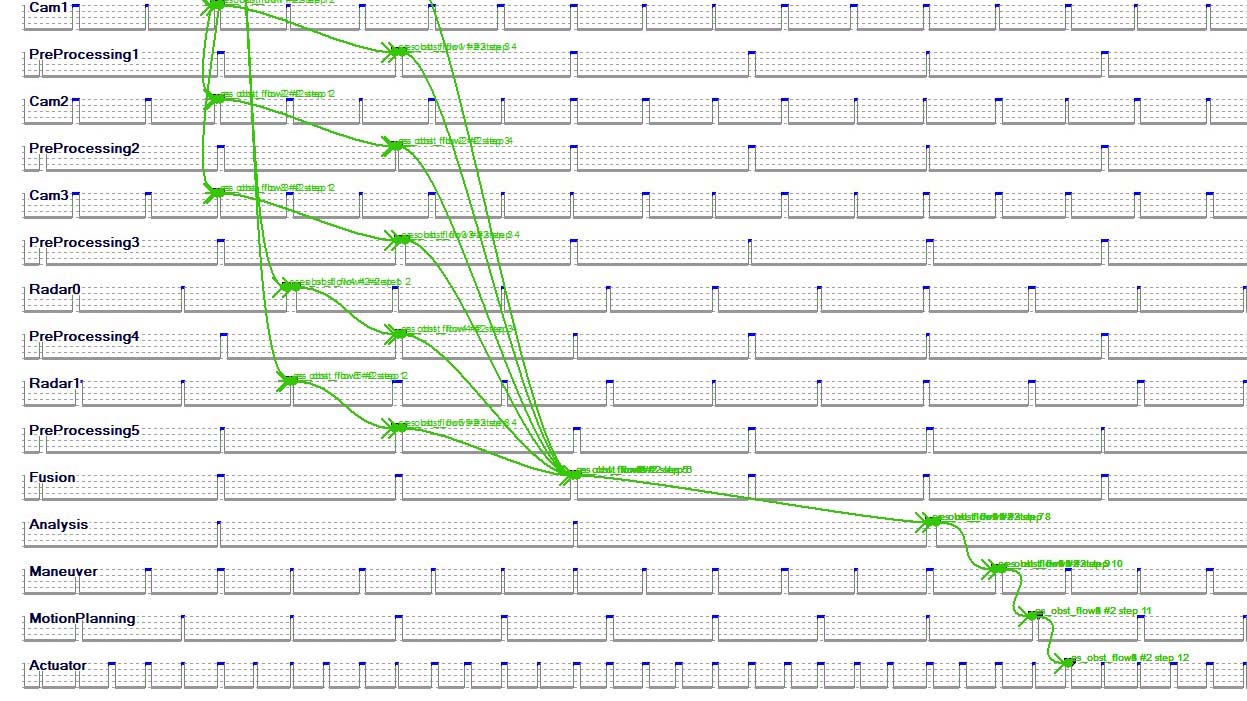

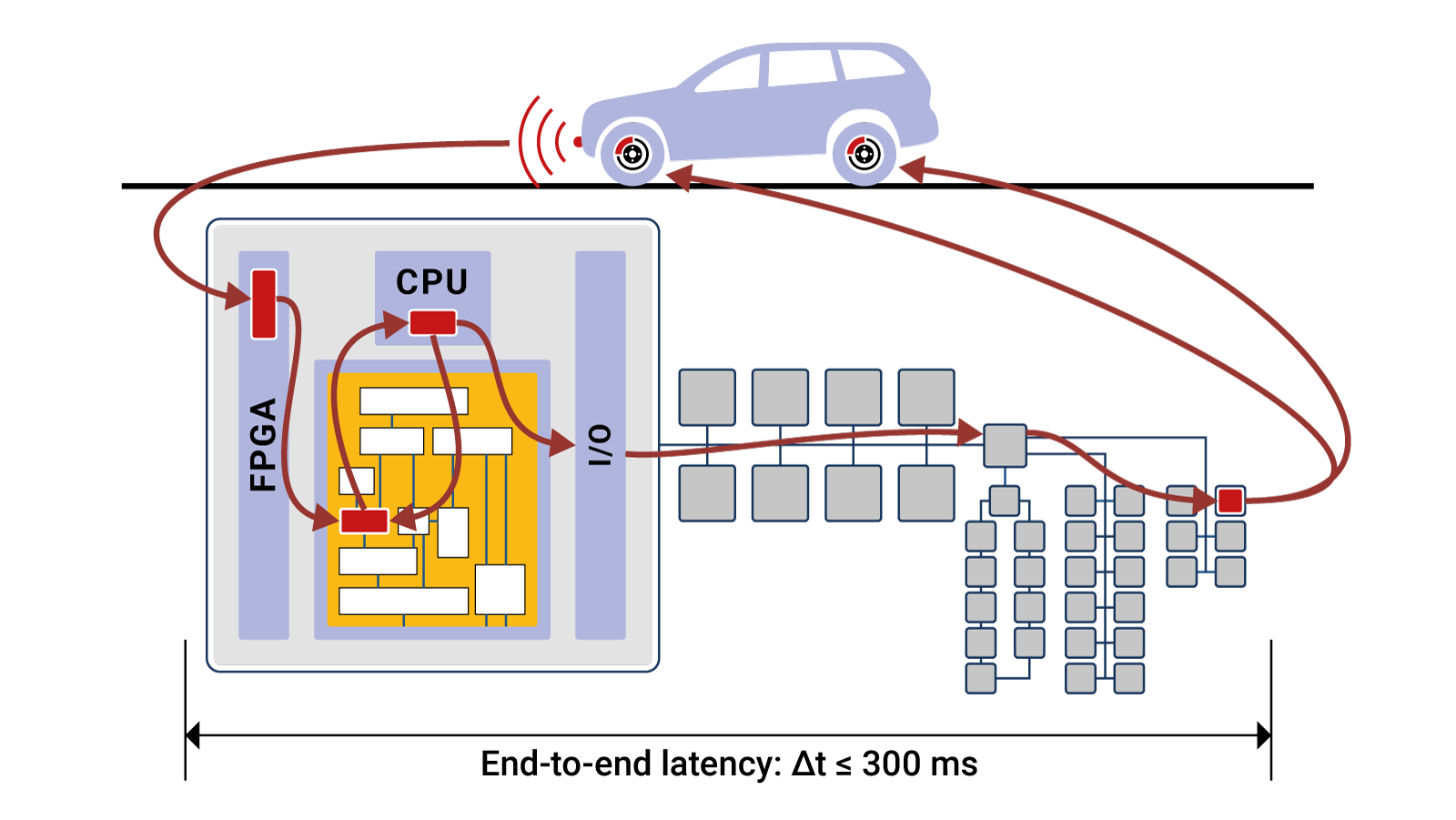

Autonomous Driving: A Real-Time Challenge

For today’s advanced driver assistance systems (ADAS), about 50 time critical event chains have to be jointly optimized – all across the system, from sensor to actuator, including embedded control units (ECUs), buses, gateway ECUs, hypervisors, and operating systems – to meet all real-time requirements.

When it comes to fully autonomous driving, well above 1000 time critical event chains have to be jointly optimized. This is not something that could be done manually anymore. This is where the INCHRON chronSUITE comes in handy, with model-based simulation and trace-based analysis & test.

Listen to the Voices of Our Automotive Customers

Click Here

AUTOSAR Adaptive Platform

The INCHRON chronSUITE supports comprehensive online event chain analysis and timing requirements evaluation, including scenarios highly relevant for the AUTOSAR Adaptive Platform, like parallel processing with multi-threading, event synchronization and sensor data fusion.

Event Chain Design for Renesas R-Car Gen3 SoC

The INCHRON chronSUITE now supports R-Car gen3, Renesas’ third generation R-Car automotive computing platform for the autonomous driving era.

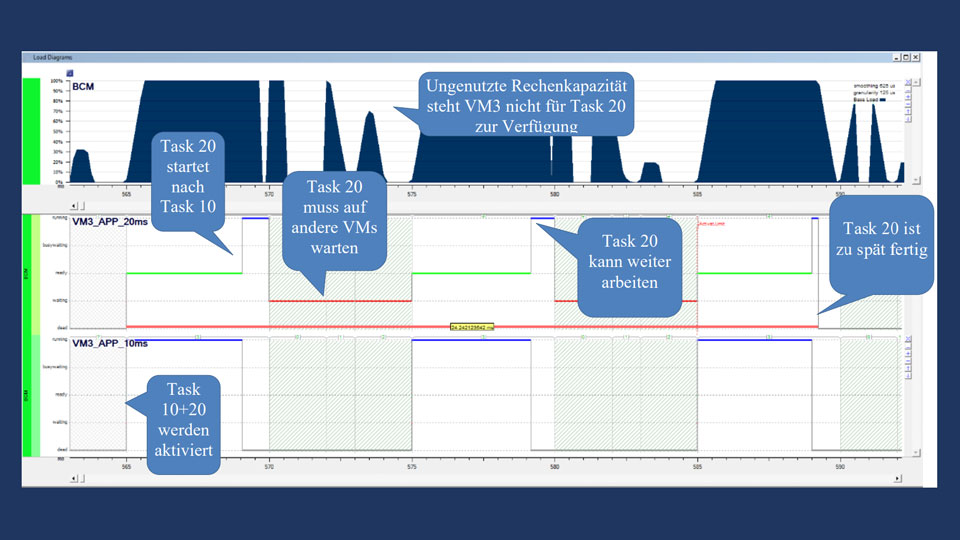

Virtualisation for Safe Software Architectures

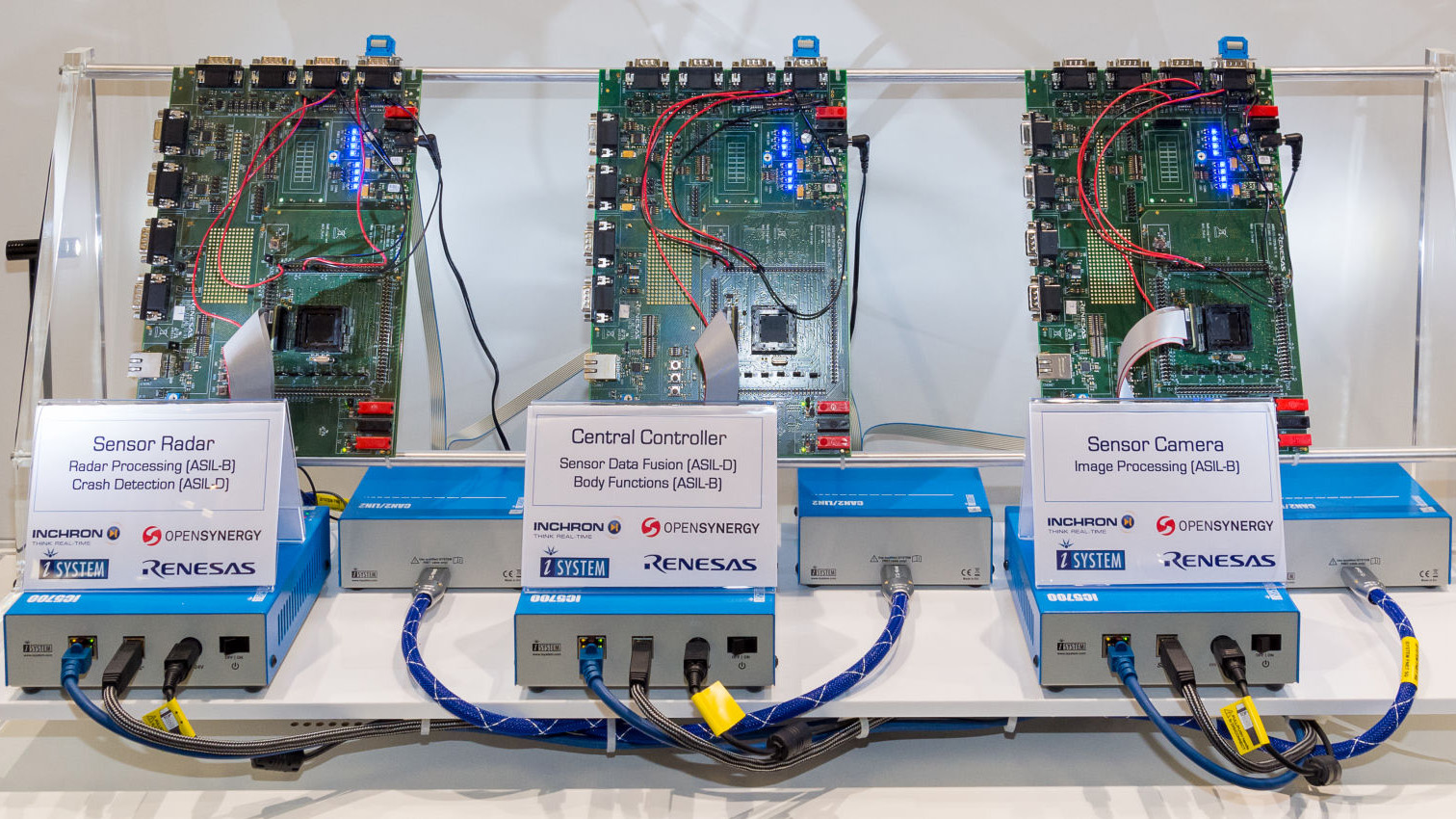

In cooperation with iSystem, OpenSynergy and Volkswagen.

In the automotive industry, the trend is towards integration of an increasing number of features, that are being developed by an increasing number of independent tier-2 suppliers, on central controllers. Any change wrt. any feature might negatively impact the whole system, such that changes affecting just a single component may result in the need to perform another full verification run on the whole system …

... read more

The objective of a Volkswagen prototyping project is to reduce the strongly increasing efforts for test and re-certification. Software encapsulation is intended to enable tier-2 suppliers to independently verify their respective software component. A hypervisor provides virtual machines (VMs) with well separated memory regions and run time supervision. Such an architecture provides a high degree of flexibility: Each VM can be developed independently of others. Applications of the same ASIL level can be combined into a single VM. We showcase best practices for the design of a hypervisor based architecture and analyse event chains with the help of tracers.

Architecture Variants of Safety-Critical Real-Time Systems

In cooperation with MethodPark, Schaeffler and INCHRON.

More and more embedded systems are considered to be safety-critical and are quite often characterised by a combination of high availability requirements and hard real-time requirements. In the automotive industry, safety features and driver assistance features are both falling into this category. In case real-time requirements are not being paid attention to right from the beginning, costly changes of system / software / hardware architecture will be among the consequences …

... read more

In the joined work, an example for a consistent approach is being discussed, covering safety analysis to functional architecture to technical architecture. Safety-critical event chains are being identified, end-to-end real-time requirements are being assigned, and time budgets are being derived – as early as in the functional architecture. Based upon the given functional architecture, possible technical architecture variants are being developed, the respective real-time behavior is being simulated, and finally the variants are being assessed in a systematic way.

Virtual Verification of Timing Requirements Shortens Development Cycles

As the complexity of features continues to increase over the lifetime of a project, the consumption of available resources in the target hardware also increases. Verifying that performance requirements remain fulfilled only at HIL (Hardware-in-The-Loop) integration not only ties up valuable test resources but, due to its operational complexity, frequently stalls an agile workflow that is striving for shorter development cycles. For this reason, the industry is currently moving towards a model-based approach with real-time simulators evaluating increasing numbers of real-time requirements even without having to turn to real target hardware.